Abstract

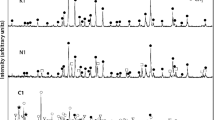

Castable porous ceramics combine the high refractoriness of ceramics, the useful characteristics of porous materials and the straightforward installation of castable systems. In this study, particles of aluminium hydroxide (Al(OH)3) and magnesium hydroxide (Mg(OH)2) of similar average size were added separately to an alumina castable (up to 67 vol.-%). During thermal treatment (1100–1500°C), variations occurred in their porosity levels, mechanical properties, phase composition and microstructure. These were related to physical-chemical changes and Al2O3-MgO solid-state reactions. Both systems have potential to be technologically useful. AH-based structures showed intermediate levels of porosity (around 60%) and higher compression strength (above 10 MPa), which enable them to be employed as sintered lightweight aggregates for refractory insulating mortars. The MH-based castables, on the other hand, exhibited higher porosity levels (above 60%) and excellent dimensional stability. They can therefore be used as primary thermal insulators for long-life services at steelmaking, cement production and petrochemical plants.

Similar content being viewed by others

References

Studart, A.R., Gunzenbach, U.T., Tervoot, E., Gauckler, L.J.: Processing routes to macroporous ceramics: A review. J. Am. Ceram. Soc. 89 (2006) [6] 1771–1789

Souza, A.D.V., Sousa, L.L., Fernandes, L., Cardoso, P.H.L., Salomão, R.: Al2O3-Al(OH)3-Based castable porous structures. J. Eur. Ceram. Soc. 35 (2015) [6] 1943–1954

Nishikawa, A.: Technology of monolithic refractories. Tokyo: Technical Report No. 33-7, PLIBRICO Japan Co. Ltd. (1984) 98–101

Salomão, R., Villas Boas, M.O.C., Pandolfelli, V.C.: Porous alumina-spinel ceramics for high temperature applications. Ceram. Inter. 37 (2011) [7] 1393–1399

Sousa, L.L., Souza, A.D.V., Fernandes, L, Arantes, V.L., Salomão, R.: Development of densification-resistant castable porous structures form in situ mullite. Ceram. Inter. 41 (2015) [8] 9443–9454

Lyckfeldt, O., Ferreira, J.M.F.: Processing of porous ceramics by starch consolidation. J. Eur. Ceram. Soc. 18 (1998) [2] 131–140

Deng, Y., Fukasawa, T., Ando, M.: Microstructure and mechanical properties of porous alumina ceramics fabricated by the decomposition of aluminum hydroxide J. Am. Ceram. Soc. 84 (2001) [11] 2638–2644

Ortega, F.S., Sepulveda, P., Pandolfelli, V.C.: Monomer systems for the gelcasting of foams. J. Eur. Ceram. Soc. 22 (2002) [9–10] 1395–1401

Dhara, S., Bhargava, P.: A simple direct casting route to ceramic foams. J. Am. Ceram. Soc. 86 (2003) [10] 1645–1650

Tang, F., Fudozi, H., Sakka, Y.: Fabrication of macroporous alumina with tailored porosity. J. Am. Ceram. Soc. 86 (2003) [12] 2050–2054

Ortega, F.S., Valenzuela, F.A.O., Scurachio, C.H., Pandolfelli, V.C.: Alternative gelling agents for the gelcasting of ceramic foams. J. Eur. Ceram. Soc. 23 (2003) [1] 75–80

Hotta, Y., Alberius, P.C.A., Bergstrom, L.: Coated polystyrene particles as templates for ordered macroporous silica structure with controlled wall thickness. J. Mater. Chem. 13 (2003) [3] 496–501

Salomão, R., Brandi, J.: Filamentous alumina-chitosan porous structures produced by gelcasting. Ceram. Inter. 39 (2013) [7] 7751–7757

Salomão, R., Brandi, J.: Macrostructures with hierarchical porosity produced from Al2O3-Al(OH)3-chitosan wet-spun fibers. Ceram. Inter. 39 (2013) [7] 8227–8235

Salomão, R., Cardoso, P.H., Brandi, J.: Gelcasting porous alumina beads of tailored shape and porosity. Ceram. Inter. 40 (2014) [10B] 16595–16601

Deng, Z.Y., Fukasawa, T., Ando, M.: High-surface-area alumina ceramics fabricated by the decomposition of Al(OH)3. J. Am. Ceram. Soc. 84 (2001) [3] 485–491

Bhattacharya, I.N., Das, S.C., Mukherjee, P.S., Paul, S., Mitra, P.K.: Thermal decomposition of precipitated fine aluminium trihydroxide. Scandinavian J. Metal. 33 (2004) [4] 211–219

Gan, B.K., Madsen, I.C., Hockridge, J.G.: In situ X-ray diffraction of the transformation of gibbsite to alpha-alumina through calcination: effect of particle size and heating rate. J. Appl. Crystallography 42 (2009) [4] 697–705

Souza, A.D.V., Arruda, C.C., Fernandes, L., Antunes, M.L.P., Kiyohara, P.K., Salomão, R.: Characterization of aluminum hydroxide Al(OH)3 for its use as a porogenic agent in castable ceramics. J. Eur. Ceram. Soc. 35 (2015) [2] 803–812

Salomão, R., Milena, L.M., Wakamatsu, M.H., Pandolfelli, V.C.: Hydrotalcite synthesis via co-precipitation reactions using MgO and Al(OH)3 precursors. Ceram. Inter. 37 (2011) [8] 3063–3070

Domínguez, C., Chevalier, J., Torrecillas, R., Fantozzi, G.: Microstructure development in calcium hexaluminate. J. Eur. Ceram. Soc. 21 (2001) [3] 381–387

Fernandes, L., Arruda, C.C., Souza, A.D.V., Salomão, R.: Characterization of synthetic amorphous silica (SAS) used in the ceramic industry. Interceram 63 (2014) [4] 220–224

Shah, S.R., Chokshi, A.H., Raj, R.: Porous Al2O3-Spinel based polycrystals that resist free-sintering. J. Am. Ceram. Soc. 91 (2008) [10] 3451–3454

Braulio, M.A.L., Castro, J.F.R., Pagliosa, C., Bittencourt, L.R.M., Pandolfelli, V.C.: From macro to nanomagnesia: designing the in situ spinel expansion. J. Am. Ceram. Soc. 91 (2009) [9] 3090–3093

Salomão, R., Pandolfelli, V.C.: Microsilica addition as an antihydration technique for magnesia-containing refractory castables. Am. Ceram. Soc. Bull. 86 (2007) [6] 9301–9309

Schneider, H., Schreuer, J., Hildman, B.: Structure and properties of mullite — a review. J. Eur. Ceram. Soc. 28 (2008) [2] 329–344

Kitamura, A., Onizuka, K., Tanaka, K.: Hydration characteristics of magnesia. Taikabutsu Overseas 16 (1995) [3] 3–11

Salomão, R., Bittencourt, L.R.M., Pandolfelli, V.C.: A novel approach for magnesia hydration assessment in refractory castables. Ceram. Inter. 33 (2007) [5] 803–810

Salomão, R., Arruda, C.C., Souza, A.D.V., Fernandes, L.: Novel insights into MgO hydroxylation: Effects of testing temperature, samples’ volume and solid load. Ceram. Inter. 40 (2014) [9B] 14809–14815

Salomão, R., Arruda, C.C., Kawamura, M.A.: A systemic investigation on the hydroxylation behavior of caustic magnesia and magnesia sinter. Ceram. Inter. In Press, corrected proof, available online 10 July 2015

Ismael, M.R., Salomão, R., Pandolfelli, V.C.: Refractory castables based on colloidal silica and hydratable alumina. Am. Ceram. Soc. Bull. 86 (2007) [9] 58–61

Bayley, J.T., Russell Jr., R.: Sintered spinel ceramics Am. Ceram. Soc. Bull. 47 (1968) [11] 1025–1029

Bayley, J.T., Russell Jr., R.: Preparation and properties of dense spinel ceramics in the MgAl2O4-Al2O3 system. Trans. Brit. Ceram. Soc. 68 (1969) [4] 159–164

Bayley, J.T., Russell Jr., R.: Magnesia-rich MgAl2O4 spinel ceramics Am. Ceram. Soc. Bull. 50 (1971) [5] 493–496

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Salomão, R., Souza, A.D.V. & Cardoso, P.H.L. A Comparison of Al(OH)3 and Mg(OH)2 as Inorganic Porogenic Agents for Alumina. Interceram. - Int. Ceram. Rev. 64, 193–199 (2015). https://doi.org/10.1007/BF03401122

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401122