Abstract

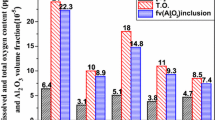

The Al2O3-MgO-Cr2O3 brick, which is used for wear lining in the ladle slag line, was selected, and the static crucible method was applied to perform a slag sticking test with the refining slag and then investigate the effect of the lime-fluorite slag melting agent with different recipes. The slag corrosion and penetration rate of samples were measured, and the microscopic structure was analyzed through a scanning electron microscope (SEM), the possible slag melting effect and the proportion of active lime and fluorite were discussed. The results show that, with an increase of CaF2 in the slag melting agent, the corrosion and penetration rate rise as well, and a corrosion ring in the sample was observed while the content of CaF2 reached the certain value. The high melting point phases including MA, CA2, CA6, C3T2 and the low melting point phases including C2AS, CAS2, CA were distributed discontinuously. Suitable slag melting agents could reduce the viscosity of the slag, form the discontinuous high melting phases and corrosion ring, so as to achieve the purpose of slag melting for ladle lining.

Similar content being viewed by others

References

Yao, J.F., Tian, S.X., Mou, J.N.: Study on the mechanism of ladle slag. Baosteel Technology (2002) [6] 59–64

Wang, J., Gu, H.Z., Wang, H.Z.: Effects of different slag on aluminum-magnesia-chrome refractory of ladle. J. Chinese Ceram. Soc. 26 (2007) [2] 390–393

Ouyang, D.G., Li, P., Hu, Q.M.: Study of slag melting agents for soaking pit furnace. Wuhan Iron and Steel Technology 37 (1999) [4] 11–14

Li, W.X.: Research and applications of premelted refining slag of LF furnace. Northeastern University (2003)

Hu, H.T.: The design of protection slag for high-speed continuous casting crystallizer. Wuhan University of Science and Technology (2000)

Wang, J., Gu, H.Z., Wang, H.Z., Liu, G.M.: Effects of different slag on aluminum-magnesia-chrome refractory of ladle. J. of Chinese Ceram. Soc. 26 (2007) [2] 390–393

Mao, H.X., Hu, H.T., Ma, G.J.: The fluorine pollution of continuous casting protecting slag to environment and countermeasures. Steelmaking 15 (1999) [3] 41–45

Sun, Y.J., Xiong, Y.C.: Development and applications of composite steel-making slag agents. Steelmaking 17 (2001) [5] 28–31, 46

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Huang, A., Gu, H. et al. Study on a Lime-Fluorite Slag Melting Agent for Ladle Slag Buildup. Interceram. - Int. Ceram. Rev. 64, 116–118 (2015). https://doi.org/10.1007/BF03401112

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401112