Abstract

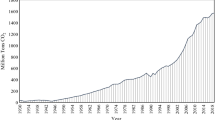

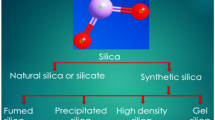

This article discusses the history and progress of silica materials production in the Czech Republic over the last 30 years, including descriptions of production capacity, characteristics and quality of individual product types as well as technological changes in the production of silica-based material. Current operational conditions and material applications are summarized. The last chapter of the article focuses on development of new kinds of silica materials and their possible utilization by customers, especially in the field of glass production.

Similar content being viewed by others

References

Lach, V., Lang, K., Novotny, B.: Fázové složení mikrostruktury některých našich a zahraničních dinasových výrobků. Stavivo 64 (1986) 343–352

Lang, K.: High-Duty Silica Refractories for Glass Melting Furnaces. Glass 72 [7] 254

Brunk, F.: Silica bricks for modern coke oven batteries. Cokemaking Internat. (2000) [2] 37–40

Lepere, K.E., Overkot, E.: Nároky na dinasové cihly jakožto na stavební materiál pro koksovací pece příští generace, (překlad). Cokemaking Internat. (1992) [1] 28–32

Zamboni, L.A., Caligaris, M.G.: Silica bricks after 15 years in service: critical study. Interceram (1997) [3] 162–166

Brunk, F., Spitz, J.: Experience with coke oven wall repairs using low thermal expansion silica brick material. Cokemaking Internat. (1998) 74–76

Snyder, W.J., Wu, K.T.: Reduction of alkali volatilization and refractory corrosion for OXY-FUEL fired furnaces. Internat. glass journal 102 (1999) 116–119

Brown, J.T., Spaulding, R.F.: New silica refractory for OXY-FUEL glass melting. Internat. glass journal 102 (1999) 120–124

Bauer, R.A., Lankhorst, A.M.: Advanced furnace design for energy efficient glass melting, Internat. glass journal 102 (1999) 128–131

Ercole, P.: Spalování kyslíku: Problémy a perspektivy rozvoje jeho použití ve výrobě obalového skla. Internat. glass journal 102 (1999) 136–139

Leblanc, J.R.: Konstrukce pece s kyslíkovým palivem a provozní úvahy pro sodno-vápenaté sklo, Internat. glass journal 102 (1999) 148–151

Vasica, L., Strouhal, T., Lang, K.: Průzkum vlastností hutných dinasových kamenů po 20 letech provozního zatížení ve stěně koksovací komory velkoprostorové KB, 30.Mezinárodní koksárenská konference, Malenovice; 9.–12.11. 2004.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lang, K., Kotouček, M. & Nevřivová, L. History, Present State and Future of Czech Silica Bricks. Interceram. - Int. Ceram. Rev. 63, 266–271 (2014). https://doi.org/10.1007/BF03401067

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401067