Abstract

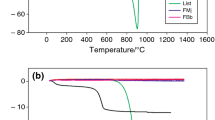

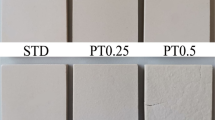

Porcelain scrap, a by-product from the table ware industry, was gradually added to a soda-lime-silica scrap-glass-containing traditional porcelanized stoneware tile body replacing sand. The effect of this addition on the vitrification and physico-mechanical properties was studied by measuring the linear shrinkage, bulk density, apparent porosity, and flexural strength of the samples heated in the temperature range 1100–1250°C. The results revealed that the presence of both glass and porcelain scrap had beneficial effects in relation to vitrification at lower temperatures and development of higher flexural strength. The improvement in strength was mainly because of the formation of well-developed needle-shaped mullite crystals and stronger pre-stress caused by the difference in thermal expansion coefficient between the glassy matrix, quartz, and mullite during the cooling process. Circumferential cracking around quartz grains was observed in quartzitic sand-containing samples. XRD studies were also carried out to determine differences in phase evolution.

Similar content being viewed by others

References

Enrico, B., Leonardo, E., Elisa, R., Antonella, T., Sandro, H.: Recycle of waste glass into glass-ceramic stoneware. J. Am. Ceram Soc. 91 (2008) [7] 2156–2162

Johnson, C.D.: Waste glass as coarse aggregate for concrete. J. Testing and Evaluation 2 (1998) 344–350

Paki, T.: Properties of masonry blocks produced with waste limestone sawdust and glass powder. Constr. and Build. Mater. 22 (2008) [7] 1422–1427

Bernardo, E., Castellan, R., Hreglich, S., Lancellotti, I.: Sintered sanidine glass-ceramics from industrial wastes. J. Eur. Ceram. Soc. 26 (2006) [15] 3335–3341

Alexander, K., Mario, P., Alessandro, H.: Sintered glass-ceramics from municipal solid waste-incinerator fly ashes. Part 1: The influence of the heating rate on the sinter-crystallisation. J. Eur. Ceram. Soc. 23 (2003) [6] 827–832

Pontikes, Y., Christogerou, A., Angelopoulos, G.N., Rambaldi, E., Esposito, L., Tucci, A.: Use of scrap soda-lime-silica glass in traditional ceramics. Glass technology. Eur. J. Glass Sc. and Tech., Part A. 46 (2005) [7] 200–206

Tucci, A., Esposito, L., Rastelli, E., Palmonari, C., Rambaldi; E.: Use of soda-lime scrap glass as a fluxing agent in a porcelain stoneware tile mix. J. Eur. Ceram. Soc. 24 (2004) 83–92

Matteucci, F., Dondi, M., Guarini, G.: Effect of soda lime glass on sintering and technological properties of porcelain stone ware tiles. Ceram. Int. 28 (2002) 873–880

Dondi, M., Marsigli, M., Fabbri, B.: Recycling of industrial and urban wastes in brick production — A review (Part 1). Tile and Brick Int. 13 (1997) [3] 218–225

Dondi, M., Marsigli, M., Fabbri, B.: Recycling of industrial and urban wastes in brick production — A review (Part 2). Tile and Brick Int. 13 (1997) [4] 302–315

Oluseyi, A.K.: Development of ceramic matrix composite for structural application using industrial waste. Post Doctoral study report under CSIR-TWAS scholarship programme, (2013)

Karamanov, A., Karamanova, E., Ferrari, M.A., Ferrante, F., Pelino, M.: The effect of fired scrap addition on the sintering behaviour of hard porcelain. Ceram. Int. 32 (2006) 727–732

Agote, I., Odriozola, A., Gutierrez, M., Santamaria, A., Quintanilla, J., Coupelle, P., Soares, J.: Rheological study of waste porcelain feed stocks for injection molding. J. Eur. Ceram. Soc. 21 (2001) 2843–2853

Dana, K., Das, S.K.: Partial substitution of feldspar by BF slag in tri-axial porcelain: Phase and microstructural evolution. J. Eur. Ceram. Soc. 24 (2004) 3833–3839

Dana, K., Dey, J., Das, S.K.: Das; Synergistic effect of fly ash and BF slag on the mechanical strength of traditional porcelain tiles. Ceram. Int. 31 (2005) 147–152

Hillebrand, W.F., Lundell, G.E.F., Bright, H. A., Hoffman, J.I.: Applied Inorganic Analysis, 2nd ed. John Wiley & Sons, New York (1953) 507–511

Magghussian, V.K., Yekta, B.E.: Single fast fired wall tiles containing Iranian iron slag. Br. Ceram. Trans. 93 (1994) [4] 141–145

Fiori, C., Brusa; A.: in Ceramic Powders, edited by Vincenzini, P., Elsevier Scientific, Amsterdam, Oxford, New York (1983) 161–172

Dana, K., Das, S.K.: High strength ceramic tiles containing Indian metallurgical slag. J. Mat. Sci. Lett. 22 (2003) [5] 387–389

Dana, K., Das, S.K.: Some studies on ceramic body composition for wall and floor tiles. Trans. Ind. Ceram. Soc. 61 (2002) [2] 83–86

Zsolnay, L.M.: Mechanical strength of porcelain. J. Am. Ceram. Soc. 40 (1957) [9] 299–306

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oluseyi, A.K., Das, S.K. Synergistic Effect of Soda-Lime-Silica Glass and Porcelain Scrap on the Vitrification Behavior of Porcelanized Stoneware Tile. Interceram. - Int. Ceram. Rev. 63, 193–197 (2014). https://doi.org/10.1007/BF03401057

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401057