Abstract

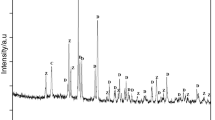

Calcium phosphate in the range of 3 to 10 mass-% partially substituted soda feldspar in five recipes in an attempt to produce white porcelain stoneware tiles. The added phosphate had a double effect on the behavior of the ceramic body during firing. The penta-valent phosphorous accommodated into the tetrahedron co-ordination of the glass melt and lowered its viscosity, leading to the early dissolution of the primary mullite and the crystallization of acicular secondary mullite, as well as fine grained nano-anorthite grains. The calcium ion played its role in increasing the degree of whiteness of the body.

The addition of 3 to 5 mass-% calcium phosphate was found to improve the degree of whiteness (L*) without compromising the MOR. The addition of 3 mass-% phosphate improved the degree of resistance to abrasion of the tile-body.

Similar content being viewed by others

References

Manfredini, T., Pellacani, G.C., Romagnoli, M., Pennisi, L.: Porcelainized stoneware tiles. Am. Ceram. Soc. Bull. 74 (1995) [5] 76–79

Dondi, M., Ercolani, G., Melandri, C., Mingazzini, C., Marsigli, M.: The chemical composition of porcelain stoneware tiles and its influence on microstructural and mechanical properties. Interceram 48 (1995) 75–83

Biffi, G.: Porcelain stoneware market in Europe: Development and future forecasts. Ceram. Inform. 385 (1999) [34] 54–60

McIlvain, J.: Ceramic Tile: Know what to look for when selecting and specifying modern ceramic tiles. The construction specifier. 47 (1994) [5] 126–136

Cavalcante, P.M.T., Dondi, M., Ercolani, G., Guarini, G., Melandri, C., Raimondo, M.: The influence of microstructure on the performance of white porcelain stoneware. Ceram. Int. 30 (2004) 953–963

Baldi, G., Generali, E., Blundo, D.S.: Preparazione, caratterizzazione ed applicazione industriale di un vetroceramico appartenente al sistema ZrO2-CaO-SiO2 (ZCS) come componente in impasti da gres porcellanato. Ceramurgia 30 (2000) 161–171

Biasini, V., Dondi, M., Guicciardi, S., Melandri, C., Raimondo, M., Generali, E., Blundo, D.S.: Mechanical properties of porcelain stoneware tiles: The effect of glass ceramic system. Key Eng. Mater. 206–213 (2002) 1799–1802

Abdel Aziz D.A., El-Fadaly, E.: Effect of LiF or B2O3 as co-flux in porcelain stoneware bodies. Interceram 57 (2008) [2] 103–107

Taylor, A., Nijhawan, K.K., Norris, A.W.: Replacing bone ash in bone china. Brit. Ceram. Trans. 78 (1979) [5] 108–112

Ibrahim, D.M., Mostafa, A.A.: Two-step firing of phosphate modified ceramic compositions. Interceram 51 (2002) [1] 6–12

Rado, P.: Bone China. Ceramic monographs. Handbook of ceramics, 2.1.3. Verlag Schmid GmbH, Freiburg (1981) 1–10

El Fadaly, E.: Study the production of anorthite porcelain from beneficiated Egyptian raw materials. Ph.D. thesis, Faculty of Science, Cairo University (2005)

Pierre, P.D.S.: Constitution of Bone China: 1. High temperature phase equilibrium studies in the system tricalcium phosphate alumina silica. J. Am. Ceram. Soc. 37 (1954) [6] 243–251

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Fadaly, E., Ibrahim, D.M. Influence of Phosphate-Substituted Flux on Microstructure and Technological Properties of White Porcelain Stoneware Tiles. Interceram. - Int. Ceram. Rev. 63, 22–25 (2014). https://doi.org/10.1007/BF03401030

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401030