Abstract

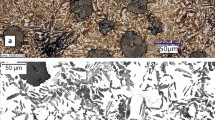

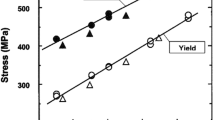

Ductile iron with a matrix of ferrite plus martensite was produced using a ductile iron alloyed with ∼0.7 wt% manganese and ∼0.5 wt% nickel. Three different volume percentages of martensite (16, 24 and 37 vol %) were formed by austenitizing in the intercritical region (ferrite + austenite) followed by quenching in a polymeric solution to room temperature. The materials were evaluated in the untempered condition and after tempering at 400C (752F) and 500C (932F) for one hour. This paper reports the effects of volume percent martensite and tempering conditions on microstructure and tensile properties. Semi-quantitative chemistry and microhardness of ferrite and martensite were also determined as a function of martensite volume percent. The results indicated that the carbon available to form the austenite during intercritical austenitizing came mainly from the carbon in the matrix and that partitioning of substitutional elements is limited. The results also showed that ultimate and yield strength and hardness increased and elongation decreased as the volume fraction of martensite increased. Tempering significantly increased the elongation with only a small decrease in the strengths.

Similar content being viewed by others

References

Sorelmetal, “The Sorelmetal Book of Ductile Iron,” vol. 1, pp. 123–30, Rio Tinto Iron and Titanium, Québec, Canada (2004).

Rundman, K.B., “Heat Treating of Ductile Irons,” ASM Handbook Volume 04: Heat Treating, ASM International, pp. 682–692 (1991).

Kobayashi, T., Yamamoto, H., “Development of High Toughness in Austempered Type Ductile Cast Iron and Evaluation of its Properties,” Met Trans A, vol. 19, pp. 319–327 (1988).

Druschitz, A.P., Aristizabal, R.E., Druschitz, E., Hubbard, C.R., Watkins, T.R., Walker, L., Ostrander, M., “In-Situ Neutron Diffraction Studies of Intercritically Austempered Ductile Iron,” Met Trans A, vol. 43, Issue 5, pp. 1468–1476 (2012).

Aristizabal, R.E., Druschitz, A.P., Druschitz, E., Bragg, R., Hubbard, C.R., Watkins, T.R., Ostrander, M., “Intercritically Austempered Ductile Iron,” AFS Transactions, vol. 119, pp. 407–413 (2011).

Druschitz, A.P., Aristizabal, R.E., Druschitz, E., Hubbard, C.R., Watkins, T.R., Ostrander, M., “Neutron Diffraction Studies of Intercritically Austempered Ductile Irons,” SAE International, Journal of Materials Manufacturing, vol. 4, pp. 111–118 (2011).

Basso, A.D., Martinez, R.A., Sikora, J.A., “Influence of Austenitizing Temperatures on Microstructure and Properties of Dual Phase ADI,” Materials Science and Technology, vol. 23, pp. 1321–1326 (2007).

Basso, A.D., Caldera, M., Chapetti, M., Sikora, J., “Mechanical Properties of Dual Phase Austempered Ductile Iron,” ISIJ International, vol. 50, pp. 302–306 (2010).

Kilicli, V., Erdogan, M., “Tensile Properties of Partially Austenitised and Austempered Ductile Irons with Dual Matrix Structures,” Materials Science & Technology, vol. 22, pp. 919–928 (2006).

Erdogan, M., Kilicli, V., Demir, B., “The Influence of Austenite Dispersion on Phase Transformation during the Austempering of Ductile Cast Iron Having a Dual Phase Matrix Structure”, International Journal of Materials Research, vol. 99, pp. 751–760 (2008).

Kilicli V., Erdogan M., “The Strain-Hardening Behavior of Partially Austenitized and the Austempered Ductile Irons with Dual Matrix Structures,” Journal of Materials Engineering and Performance, vol. 17, pp. 240–249 (2008).

Kilicli, V., Erdogan, M., “The Nature of the Tensile Fracture in Austempered Ductile Iron with Dual Matrix Microstructure,” Journal of Materials Engineering and Performance, vol. 19, pp. 142–149 (2010).

Valdés, C., Pérez, M.J., Figueroa, M., Ramírez, L.E., “Austempered Ductile Irons with Dual Phase Matrix Structures,” Revista Mexicana de Fisica, vol. 55, pp. 48–51 (2009).

Erdogan, M., Kilicli, V., Demir, B., “Transformation Characteristics of Ductile Iron Austempered from Intercritical Austenitizing Temperature Ranges,” Journal of Materials Science and Engineering, vol. 44, pp. 1394–1403 (2009).

Basso, A.D., Sikora, J., “Review on Production Processes and Mechanical Properties of Dual Phase Austempered Ductile Iron,” International Journal of Metalcasting, vol. 6, pp. 7–14 (2012).

Rashidi, M., Moshrefi-Torbati, M., “Effect of Tempering Conditions on the Mechanical Properties of Ductile Cast Iron with Dual Matrix Structure (DMS),” Materials Letters, vol. 45, pp. 203–207 (2000).

Kocatepe, K., Cerah, M., Erdogan, M., “Effect of Martensite Volume Fraction and its Morphology on the Tensile Properties of Ferritic Ductile Iron with Dual Matrix Structures,” Journal of Materials Processing Technology, vol. 178, pp. 44–51 (2006).

Cerah, M., Kocatepe K., Erdogan, M., “Influence of Martensite Volume Faction and Tempering Time on the Tensile Properties of Partially Austenitized in the (α+γ) Temperature Range and Quenched + Tempered Ferritic Ductile Iron,” Journal of Materials Science, vol. 40, pp. 3453–3459 (2005).

ASTM International, “ASTM E8-04 Standard Test Methods for Tension Testing of Metallic Materials,” Annual Book of ASTM Standards, vol. 3.01, pp. 62–85 (2005).

Speich, G.R., Demarest, V.A., Miller R.L., “Formation of Austenite during Intercritical Annealing of Dualphase Steels,” Met. Trans. A, vol. 12, pp. 1419–1428 (1981).

Taran, Y.V., Daymond, M.R., Schreiber, J., “Interplay of Stresses Induced by Phase Transformation and Plastic Deformation during Cyclic Load of Austenitic Stainless Steel,” Physica B, vol. 350, pp. 98–101 (2004).

Jenkins, L.R., Forrest, R.D., “Ductile Iron” ASM Handbook, Volume 01: Properties and Selection: Irons, Steels, and High-Performance Alloys, pp. 33–55 (1990).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Aristizabal, R., Foley, R. & Druschitz, A. Intercritically Austenitized Quenched and Tempered Ductile Iron. Inter Metalcast 6, 7–14 (2012). https://doi.org/10.1007/BF03355534

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355534