Abstract

The mechanical properties of ductile iron (DI) and compacted graphite iron (CGI) are measured and reported on standard machined specimens (as per ASTM). However, most castings retain most of the as-cast surface. This surface layer (the casting skin) includes both surface and subsurface features. Because of the casting skin, the mechanical properties of the part are typically significantly lower than those found on standard ASTM machined specimens.

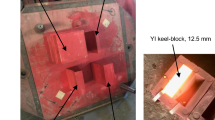

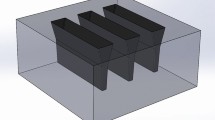

The technical objectives of this research were to identify the individual features that together define skin quality in DI and CGI, to develop a method for the measurement of skin thickness, and to quantify the influence of the skin of thin wall (2 to 6 mm) DI castings on its tensile properties.

The features of the casting skin include surface (roughness) and subsurface (graphite degradation, graphite depletion, pearlitic rim) elements. Graphite shape measurements were used to evaluate graphite degradation. Graphite area measurements were used to determine the thickness of the graphite depleted layer. Microhardness measurements are useful when a pearlitic rim occurs. The average thickness of the skin for thin wall DI castings ranged from 0.15 to 0.45mm, while for CGI it ranged from 0.7 to 2.5mm.

It was found as expected that the strength decreased with thicker casting skin. The tensile and yield strength skin factor (ratio between the strength of as-cast and machined test plates) was about 0.93. This should be viewed as an upper limit, as only one of the surfaces of the mechanical properties test plate was as-cast. More significant reduction in strength should be expected.

Diffusion calculations confirmed that graphite degradation, graphite depletion and the pearlitic rim are the result of magnesium and carbon depletion at the mold/metal interface because of their oxidation. Alternatively, carbon diffusion from the mold can also result in pearlitic rim formation.

Similar content being viewed by others

References

G.M. Goodrich and R.W. Lobenhofer, “Effect of Cooling Rate on Ductile Iron Mechanical Properties”, AFS Transactions, vol. 110 (2002) pp. 1003–1032.

F. Mampaey, P. Li and E. Wittink, “Variation of Gray Iron Strength Along the Casting Diameter”, AFS Transactions, vol. 111 (2003) pp. 755–772.

J.W. Torrance and D.M. Stefanescu, “Investigation on the Effect of Surface Roughness on the Static Mechanical Properties of Thin-Wall Ductile Iron Castings”, AFS Transactions, vol. 112 (2004) pp. 757–772.

L.P. Dix, R. Ruxanda, J. Torrance, M. Fukumoto and D.M. Stefanescu, “Static Mechanical Properties of Ferritic and Pearlitic”, AFS Transactions, vol. 111 (2003) pp. 895–910.

C. Labrecque, M. Gagne, A. Javaid, and M. Sahoo, “Production and Properties of Thin-Wall Ductile Iron Castings”, International Journal of Cast Metals Research, Vol. 16, Part 1/3 (2003) pp. 313–318.

R.C. Aufderheide, R.E. Showman and M.A. Hysell, “Controlling the “Skin Effect” on Thin-Wall Ductile Iron Castings”, AFS Transactions, vol. 113 (2005) pp. 567–579.

F.C. Duncan and J. Kroker, “Difficulties in Controlling and Measuring Flake Skin in CGI”, WFO Technical Forum, Dusseldorf, Germany (2007).

Azterlan, Euskadia, Spain, Private Communication.

C. Labrecque, M. Gagne, P. Cabanne, C. Francois, C. Becret, and F. Hoffman, “Comparative Study of Fatigue Endurance Limit For 4 and 6 MM Thin Wall Ductile Iron Castings”, International Journal of Metalcasting, vol. 2, issue 2 (2008) pp. 7–17.

D.M. Stefanescu and F.R. Juretzko, “Study of the Effect of Some Process Variables on the Surface Roughness and the Tensile Properties of Thin Wall Ductile Iron Castings”, AFS Transactions, vol. 115 (2007) pp. 637–645.

R.E. Ruxanda, D.M. Stefanescu, T.S. Piwonka, “Microstructure Characterization of Ductile Thin Wall Iron Castings”, AFS Transactions, vol. 110 (2002) pp. 1131–1147.

D.M. Stefanescu, Stephanie Collins and J. Massone, “Study of the Effect of the Casting Skin on the Tensile Properties of Light Weight Ductile Iron Castings” AFS Report (Jan. 2008).

D.M. Stefanescu, “Thermodynamic Properties of Iron-Base Alloys”, ASM Handbook, Vol. 15: Casting (1988) pp. 61–70.

A. Habibollahzadeh and J. Campbell, “Surface Films on Liquid Grey Cast Iron: A Study by SEM”, AFS Transactions, vol. 111 (2003) pp. 675–684.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stefanescu, D., Wills, S., Massone, J. et al. Quantification of Casting Skin in Ductile and Compacted Graphite Irons and Its Effect on Tensile Properties. Inter Metalcast 2, 7–28 (2008). https://doi.org/10.1007/BF03355433

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355433