Abstract

Recent work with aluminum alloy castings indicated that bubbles of oxidising gases emanating from sand cores produced trails of oxide that could form leakage defects. The present work was conducted to determine if similar behavior could be observed in iron castings.

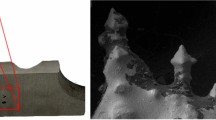

Leakage defects in large grey iron diesel engine crankcase castings were therefore opened by fracturing. The fracture surfaces were subjected to an SEM study, revealing the leak paths that were determined to be bubble trails resulting from the blowing of a core. There appeared to be two distinct types of leak structure.

-

1)

Well-formed clusters of perhaps 10 or 20 bubble trails. Some trails were formed from films that were translucent when viewed by SEM, being only a few tens of nanometres thick and seemed likely to be amorphous, and possibly recorded the passage of single bubbles. Thicker films probably originated from the passage of multiple oxidising bubbles, and had crystallised, consisting of crystals approximately 1 µm diameter. Both thin and thick trails appeared to consist of tubes formed from films of iron silicates. These are thought to originate from fairly modest core blow events characterised by only microscopic exits at the surface of the casting.

-

2)

Severe damage from more serious blow events more akin to volcanic eruptions, creating deep craters on the casting surface measured in millimetres. Internal features include masses of siliceous oxide slag material that was thought to be the residue of early silicate trails, plus highly damaged carbonaceous trails composed of what appeared to be graphitic films. It is not clear whether the different bubble trail compositions can be attributed to the different oxidising and reducing gases evolved by the core during the progress of the decomposition of its organic binder or whether the effect is a natural consequence of the oxidation of cast iron at different temperatures.

Similar content being viewed by others

References

J Campbell “Castings” 1st Edition 1991 pp 21–24.

J Campbell “Castings” 2nd Edition 2003 pp 50–53, 156–160.

M Divandari and J Campbell; Trans AFS 2001 109 201–212

K-H Caspers; AFS International Cast Metals Journal 1980 5 (1) 20–22.

X Cao and J Campbell; University of Birmingham, UK. Unpublished work 2002.

Y Kuroda and H Takada; AFS Cast Metals Research Journal 1970 6 (2) 63–74.

L Petrzela; Foundry Trade Journal 1968 October 31, 693–696

R L Naro; AFS Transactions 2004 112 527–545.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Campbell, J. Leakage Defects via Bubble Trails in Grey Iron Castings. Inter Metalcast 1, 7–20 (2007). https://doi.org/10.1007/BF03355414

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355414