Abstract

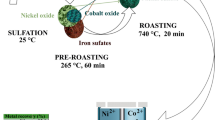

As an alternative to the smelting of nickel sulfides, nickel may be leached from laterite by copper sulfate solutions. The copper sulfate can be regenerated to form a continuous part of the process, leading to economic and environmental advantages.

Similar content being viewed by others

References

E. T. Carlson and C. S. Simons, “Acid Leaching Moa Bay’s Nickel,” J. Met., 12 (3) (1960) pp. 206–13

M. H. Caron, “Fundamental and Practical Factors in Ammonia Leach of Nickel and Cobalt Ores,” Trans. TMS-AIME, 188 (1950) pp. 67–90

N. Zubryckyj, P. T. O’Kane, and V. N. Mackiw, “Leaching Process for Reduced Nickel and Cobalt-Bearing Lateritic Ores,” Canadian Patent 811,078, April 1969

L. G. Stevens, L. A. Goeller, and M. Miller, “Hydrometallurgical Recovery of Nickel Values from Laterites,” U.S. Patent 3,903,241, September 1975

C. E. O’Neill, “Acid Extraction of Nickel from Lateritic Ores” U.S. Patent 3,773,891, October 1972

K. Matsuzuka, “A Method of Treating Nickel-Chromium-Containing Iron Ores,” British Patent 951,063, March 1964

N. Hedley and J. J. Kress, “Treatment of Garnierite Ores,” U.S. Patent 2,349,223, May 1944

P. E. Queneau and H. J. Roorda, “Impressive New Process Uses Chlorine and Seawater for Improved Recovery of Cobalt from Nickeliferrous Limonites,” Mining Eng., 23 (8) (1971) pp. 70–3

J. R. Boldt, “Extractive Metallurgy of Sulfide Ores” in The Winning of Nickel, P. Queneau ed., pp. 348, 370, Longmans, Toronto, 1967

D. J. MacKinnon, “Recovery of Copper by Cementation on Nickel Powder,” Can. Met. Quart., 13 (3) (1974) pp. 473–77

R. M. Nadkami, C. E. Jelden, K. C. Bowles, H. E. Flanders, and M. E. Wadsworth, “A Kinetic Study of Copper Precipitation on Iron,” Trans. TMS-AIME, 239 (4) (1967) pp. 581–5

R. D. Groves, “Preparation of Copper Powder from Leach Solutions after Precipitation with Iron,” U.S. Bur. Mines, Rept. Invest. No. 6486, 1964

D. J. MacKinnon, T. R. Ingraham, and R. Kerby, “Copper Cementation on Nickel Discs,” Can. Met. Quart., 10 (3) (1971) 165–9

R. L. Miller and M. E. Wadsworth, “Kinetics of Copper Cementation on Nickel,” presented at Annual Meeting of AIME, February 25-29, 1968, New York, N.Y.

S. I. Mitrofanov, “Combined Process of Concentration and Hydrometallurgical Treatment of Oxidized Copper Ores,” Chem. Abstr., 52 (1958) 7052e

V. F. Faleev, “Reprocessing of Dzhezkazgan Oxidized Ores by the Mostovich Method,” Chem. Abstr., 61 (1964) p. 3973h

K. Kinson, J. E. Dickeson, and C. B. Belcher, “The Determination of Metallic Iron, Nickel and Cobalt in Reduced Ores and Oxides,” Anal. Chim. Acta., 41 (1968) pp. 107–12

P. D. Bush, L. F. Engle, E. H. Gates, and M. D. Vijayaraghavan, “The Pressure Leaching—Cementation—In—Pulp Process for Nickel Laterites and Sulfides” in International Symposium on Hydrometallurgy, D. J. I. Evans and R. S. Shoemaker eds., pp. 63–80, AIME, New York, N.Y., 1973

Author information

Authors and Affiliations

Additional information

P. A. Distin is Associate Professor of Metallurgy at McGill University, Montreal, Quebec. He received his BSc and PhD degrees in Metallurgical Engineering from the University of London, England. He was a Post-Doctoral Fellow with the National Research Council of Canada and has also worked at the Sheridan Park Laboratories of INCO Metals Co. of Canada, near Toronto.

Rights and permissions

About this article

Cite this article

Distin, P.A. Nickel Extraction from Reduction-Roasted Laterite Ores by Copper Sulfate Leaching. JOM 30, 30–35 (1978). https://doi.org/10.1007/BF03354389

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03354389