Summary

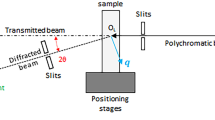

The role of residual stresses in the premature failure of metallic components has long been recognized. However, the most prevalent methods of measuring these stresses are at least partly, if not completely, destructive. This, as well as the availability of more rapid and portable x-ray diffraction instrumentation, has led to a renewed interest in this nondestructive residual stress measurement methodology.

This paper discusses the three most popular x-ray diffraction techniques for measuring residual stresses and describes theoretical, as well as experimental, results showing the sensitivity of two of the techniques to specimen-to-detector distance, i.e., displacement, errors. Further, the inherent theoretical advantage of the double-exposure over the single-exposure technique is derived. Theoretical and experimental evidence is then offered showing experimental difficulties in realizing this advantage. Finally, the inherent insensitivity of the single-exposure technique to displacement errors is demonstrated.

Similar content being viewed by others

References

“Methods of Residual Stress Measurement-SAEJ936,” SAE, Warrendale, Pennsylvania, 1965.

C. O. Ruud, “A Review of Nondestructive Method for Residual Stress Measurement,” J. Metals, 33(7), 1981, pp. 35–40.

“Residual Stress Measurement by X-Ray Diffraction-SAE J784a,” SAE Warrendale, Pennsylvania, 1971.

B. D. Cullity, Elements of X-Ray Diffraction, 2nd Ed., Addison-Wesley, Reading, Massachusetts

J. T. Norton, “X-Ray Stress Measurement by the Single-Exposure Technique,” Adv. in X-Ray Anal., Vol. 11, Plenum Press, New York, 1968, p. 401–410.

C. O. Ruud, “Position-Sensitive Detector Improves X-Ray Powder Diffraction,” Ind. Res. and Dev., January 1983.

B. D. Cullity, “Some Problems in X-Ray Stress Measurements,” Adv. in X-Ray Anal., Vol. 20, Plenum Press, New York, 1977, pp. 259–271.

C. O. Ruud, P. S. DiMascio, and D. J. Snoha, “A Miniature Instrument for Residual Stress Measurement,” Adv. in X-Ray Anal., Vol. 27, Plenum Press, New York, to be published in 1984.

Author information

Authors and Affiliations

Additional information

Dr. Ruud received his BS in physical metallurgy from Washington State University, and his MS from San Jose State College and PhD from the University of Denver, both in materials science. At Penn State, he is principal investigator for research in NDT&E methods for materials measurement and conducts research in residual stress measurement and measurement methodology development. He is a member of The Metallurgical Society of AIME.

Mr. Snoha received his degree in mechanical engineering from Pennsylvania State University. His current research activities deal primarily with residual stress measurement instrumentation and methodology.

Rights and permissions

About this article

Cite this article

Ruud, C.O., Snoha, D.J. Displacement Errors in the Application of Portable X-Ray Diffraction Stress Measurement Instrumentation. JOM 36, 32–38 (1984). https://doi.org/10.1007/BF03339934

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03339934