Abstract

Separation of metal laden solid wastes for their recycling utilization using passive pulsed air and active pulsing air classifiers was studied. Laboratory investigation showed that the active pulsing air separator performs more efficiently than the passive pulsed air separator due to the ability to accurately control operating parameters. By studying the difference of drag coefficients of the particles moving through the airflow of varying Reynolds numbers, models of the dynamic particle motion were developed and a computer simulation was prepared. Results of the simulation were reported to predict the observed results with artificial tracing spheres being separated by the laboratory equipment. Two different, real world feed materials were separated with the laboratory scale active pulsing air classifier. The discarded catalyst consisting of precious metal components and sintered magnetic beads was separated with the separation efficiency, of 97.6 %. The second real-world feed, electronic scrap crushed to a size of 0.5 to 2 mm, showed a separation efficiency of 92.41 %. At the same time, the grade of the recovered concentrate of metals was above 98 %.

Similar content being viewed by others

References

Batchelor, G. K., (1967). An introduction to fluid dynamics. Cambridge Univ. Press, Cambridge, UK.

Birkhoff, G., (1960). Hydrodynamics: A study in logic, fact, and similitude. Revised Ed., Princeton Univ. Press, New York, USA.

Brush, L. M.; Wo, H. W.; Yen, B. C., (1964). Accelerated motion of a sphere in a viscous fluid. J. Hydrodynamics, 90(1), 149–160 (12 pages).

Cao, Y. J.; Wen, X. F.; Zhao, Y. M.; Wang, Q. Q, (2002). Research on selective shredding of wasted printed circuit boards. J. China Univ. Min. Tech., 12(1), 25–29 (5 pages).

Carstens, M. R., (1952). Accelerated motion of a spherical particle. Transactions of American Geophysics Union, 33(5), 713–721 (9 pages).

Crowe, P. B.; Peirce, J. J., (1988). Particle density and air-classifier performance. J. Environ. Eng., 114(2), 282–399 (18 pages).

Cui, J.; Forssberg, E., (2003). Mechanical recycling of waste electric and electronic equipment: A review. J. Hazard Mater., B 99(3), 243–263 (21 pages).

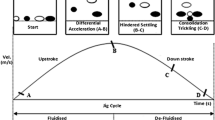

Duan, C. L.; He, Y. Q.; Wang, H. F.; Zuo, W. R., (2003). Separating mechanism of passive pulsing air classifier. J. China Univ. Min. Tech., 32(6), 725–728 (4 pages).

Feng, X. D.; Huang, W. L.; Yang, C.; Dang, Z., (2009). Chemical speciation of fine particle bound trace metals. Int. J. Environ. Sci. Tech., 6(3), 337–346 (10 pages).

He, Y. Q.; Wang, H. F.; Duan, C. L.; Song, S. L.; Zhao, Y. M., (2005). Airflow fields simulation on passive pulsing air classifiers. J. S. Afr. Ins. Min. Metal., 106(4), 525–531 (7 pages).

He, Y. Q.; Zhao, Y. M.; Duan, C. L.; Zuo, W. R.; He, J. F., (2007). Mechanism of active pulsing air classification and its application to waste PCBs disposal. in: International Symposium on Environmental Science and Technology. Beijing, China 8–11 Nov.

He, Y. Q.; Zhao, Y. M., (2009). Technology of pulsing air separation. Chem. Eng. Industry Press, Beijing, China.

Hjelmfelt, A. T.; Mockros, L. F., (1967). Stokes flow behavior of an accelerating sphere. J. Eng. Mech., 93(6), 87–102 (16 pages).

Houghton, E. L.; Carpenter, P. W., (2002). Aerodynamics for Engineering Students. 5th Edition, Butterworth — Heinemann, Oxford, MA, USA.

Igwe, J. C.; Abia, A. A.; Ibeh, C. A., (2008). Adsorption kinetics and intraparticulate diffusivities of Hg, As and Pb ions on unmodified and thiolated coconut fiber. Int. J. Environ. Sci. Tech., 5(1), 83–92 (10 pages).

Ito, S., (2003). Development of pneumatic separator using acceleration column. Metallic ore dressing abroad, 23(5), 38–42 (6 pages).

Jackson, C. R.; Stessel, R. I.; Peirce, J. J., (1988). Passive pulsing air-classifier theory. J. Eng., 114(1), 106–119 (14 pages).

Joseph, W. L., (1979). Coal Preparation. The American Institute of Mining, Metallurgical, and Petroleum Engineers, INC., New York.

Karanfilian, S. K.; Kotas, T. J., (1978). Drag on a sphere in unsteady motion in a liquid at rest. J. Fluid Mech., 87(1), 85–96 (12 pages).

Khanfekr, A.; Arzani, K.; Nemati, A.; Hosseini, M., (2009). Production of perovskite catalysts on ceramic monoliths with nanoparticles for dual fuel system automobiles. Int. J. Environ. Sci. Tech., 6(1), 105–122 (8 pages).

Kozlowski, J.; Mazurck, T.; Czyzyk, H., (2000). The recovering metals and alloys from the electronic scrap. Metal, 54(11), 645–649 (5 pages).

Luga, A.; Morar, R.; Samuila, A., (2001). Electrostatic separation of metals and plastics from granular industrial wastes. IEE Proc. Sci. Meas. Tech., 148(2), 47–54 (8 pages).

Mockros, L. F.; Lai, R. Y. S., (1969). Validity of stokes theory for accelerating spheres. J. Eng. Mech., 95(3), 629–640 (12 pages).

Nwuche, C. O.; Ugoji, E. O., (2008). Effects of heavy metal pollution on the soil microbial activity. Int. J. Environ. Sci. Tech., 5(3), 409–414 (6 pages).

Nwachukwu, M. A.; Feng, H.; Alinnor, J., (2010). Assessment of heavy metal pollution in soil and their implications within and around mechanic villages. Int. J. Environ. Sci. Tech., 7(2), 347–358 (12 pages).

Olayiwola, O.; Walzel, P., (2007). Flow pulsation and modified dust surface for process heat transfer intensification. Int. J. Chem. Reactor Eng., 5(A71), 1–9 (9 pages).

Peirce, J. J.; Wittenberg, N., (1984). Zig-zag configurations and air classifier performance. J. Energ. Eng., 110(1), 36–47 (12 pages).

Senden, M. M. G., (1978). Performance of zig-zag air classifiers at low particle concentrations. Ph. D Dissertation of the Eindhoven Univ. Tech., Eindhoven, Netherlands.

Shah, B. A.; Shah, A. V.; Singh, R. R., (2009). Sorption isotherms and kinetics of chromium uptake from wastewater using natural sorbent material. Int. J. Environ. Sci. Tech., 6(1), 77–90 (14 pages).

Stessel, R. I.; Peirce, J. J., (1986). Comparing pulsing classifiers for waste-to-energy. J. Energ. Eng., 112(1), 1–13 (13 pages).

Stessel R. I., (1992). Controlling pulsed incompressible flow. J. Eng., 118(1), 1–17 (17 pages).

Taub, J. B.; Peirce J. J., (1983). Instabilities in air classification of fuels. J. Energ. Eng., 109(2), 74–87 (14 pages).

Tehrani, S. M.; Karbassi, A. R.; Monavari, S. M.; Mirbagheri, S. A., (2010). Role of E-shopping management strategy in urban environment. Int. J. Environ. Res. 4(4), 681–690 (10 pages).

Tippayawong, N.; Khongkrapan P., (2009). Development of a laboratory scale air plasma torch and its application to electronic waste treatment. Int. J. Environ. Sci. Tech., 6(3), 407–414 (8 pages).

Wang, X. F.; Xiong, A. K., (2003). Advanced fluid mechanics. Huazhong Univ. Sci. Tech. Press, Wuhan, China.

Wang, H. F., (2004). Study on the separation mechanism and airflow pattern of pulsed air classifiers. Master’s Thesis of China Univ. Min. Tech., Xuzhou, China.

Winter, D.; Courtney, K., (2001). From here to eternity: recycling Hi-tech junk. Waste Age, 32(3), 186–190 (5 pages).

Wu, J.; He, Ch., (2010). Experimental and modeling investigation of sewage solids sedimentation based on particle size distribution and fractal dimension. Int. J. Environ. Sci. Tech,. 7(1), 37–46 (10 pages).

Zhang, S.; Forssberg, E.; Menad, N., (1998). Metals recycling from electronic scrap by air table separation-theory and application. In: The TMS Annual Meeting: EPD Congress, San Antonio, USA 16–19 Feb.

Zhang, Z. X.; Dong, Z. N., (2004). Viscous fluid mechanics. Tsinghua Univ. Press, Beijing, China.

Zhao, Y. M.; He, Y. Q.; Duan, C. L.; Zuo, W. R.; Wen, B. F., (2008). Simulation and application of the active pulsing air classification. in: Proceedings of the 11 th International Mineral Processing Symposium. Belek-Antalya, Turkey 11–14 Oct.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, Y., Duan, C., Wang, H. et al. Separation of metal laden waste using pulsating air dry material separator. Int. J. Environ. Sci. Technol. 8, 73–82 (2011). https://doi.org/10.1007/BF03326197

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03326197