Abstract

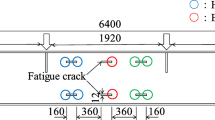

This study investigates improvement effects of fatigue strength by burr grinding and hammer peening treatments. High-cycle fatigue tests with constant and variable amplitude loadings are performed on out-of-plane gusset plate specimens. Test results indicate that the reduction of stress concentration by the burr grinding greatly improves the fatigue life under both the constant and variable amplitude loadings. For the variable amplitude loading, the damage accumulation D obtained by Miner’s rule with the mean curve of constant amplitude loading is conservative (D > 1.5). However, under the variable amplitude loading, since the beneficial effects of the peening treatment on the fatigue life decrease due to the relaxation of compressive residual stress, the damage accumulations in specimens prepared by cleaning and subsequent hammer peening are extremely non-conservative (D ≈ 0.2). In addition, the stress patterns do not affect the fatigue life significantly.

Similar content being viewed by others

References

Konishi T., Takahashi K. and Miki C.: Application of high strength steel on steel bridge and its effect on weight reduction, Proceedings of JSCE, 2000, vol. 654, pp. 91–103.

Okada J., Murakami T. and Kawabata A.: Study of longer continuous composite two I-girder bridges utilizing the bridge high performance steels, Proceedings of JSCE, 2007, vol. 63, no. 2, pp. 141–155.

Roy S., Fisher J.W. and Yen B.T.: Fatigue resistance of welded details enhanced by ultrasonic impact treatment (UIT), International Journal of Fatigue, 2003, vol. 25, no. 9-11, pp. 1239–1247.

Weich I., UmmenhoferT., Nitschke-Pagel Th., Dilger K. and Eslami H.: Fatigue behaviour of welded high strength steels after frequency mechanical post-weld treatments, IIW Doc. XII I-2154-07, 2007.

Weich I.: Edge layer condition and fatigue strength of welds improved by mechanical post-weld treatment, Doc. IIW-2075, Welding in the World, 2011, vol. 55, no. 1/2, pp. 3–12.

Kuhlmann U., Dürr A. and Günther H.-P.: Application of post-weld treatment methods to improve the fatigue strength of high strength steels in bridges, IABMAS-06, 2006.

Haagensen P.J. and Maddox S.J.:IIWRecommendations on post weld fatigue life improvement of steel and aluminium structures, IIW Document XIII-2200r7-07, 2010.

Schajer G.S.: Application of finite element calculations to residual stress measurements, Materials and Technology, 1981, vol. 103, no. 2, pp. 157–163.

Schajer G.S.: Measurement of non-uniform residual stresses using the hole drilling method — Part I — Stress calculation procedures, Materials and Technology, 1988, vol. 110, no. 4, pp. 338–343.

Schajer G.S.: Measurement of non-uniform residual stresses using the hole drilling method — Part II — Practical application of the integral method, Materials and Technology, 1988, vol. 110, no. 4, pp. 344–349.

Zhang Y-H and Maddox S.J.: Investigation of fatigue damage to welded joints under variable amplitude loading spectra, International Journal of Fatigue, 2009, vol. 31, no. 1, pp. 138–152.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tai, M., Miki, C. Improvement Effects of Fatigue Strength by Burr Grinding and Hammer Peening Under Variable Amplitude Loading. Weld World 56, 109–117 (2012). https://doi.org/10.1007/BF03321370

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321370