Abstract

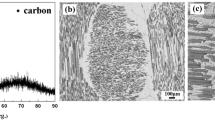

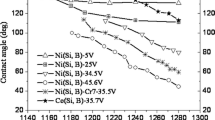

Carbon fibre-reinforced silicon carbide matrix composite (Cf/SiC composite) is a new heat-resistant ceramic matrix composite, and it shows a high potential for applications in high temperature environments. However, reliable joining technology is still lacking for this material. In the present paper, the contact angles of Pd-Co-V system alloys on Cf/SiC composite were measured using the sessile drop method. On this basis, one kind of Pd-Co-V alloy, in the powder form of the mixture of elemental components was used as brazing filler metal, and Cf/SiC composite joints were achieved after brazing at 1 523 K for 20 min. The microstructure of the Cf/SiC composite joints was examined with SEM and XEDS. It was found that elements Pd and V in the filler metal participated in the interfacial reactions between the composite and the brazing filler metal. The reaction products were analysed, and the joining mechanism was discussed.

Similar content being viewed by others

References

McDermid J.R. and Drew R.A.L.: Thermodynamic brazing alloy design for joining silicon carbide, Journal of the American Ceramic Society, 1991, vol. 74, no. 8, pp. 1855–1860.

McDermid J.R., Pugh M.D. and Drew R.A.L.: The interaction of reaction-bonded silicon carbide and Inconel 600 with a nickel-based brazing alloy, Metallurgical Materials Transactions A, 1989, vol. 20, no. 9, pp. 1803–1810.

Tong Q. and Cheng L.: Liquid infiltration joining of 2D C/SiC composite, Science and Engineering of Composite Materials, 2006, vol. 13, no. 1, pp. 31–36.

Xiong J., Li J., Zhang F. and Huang W.: Joining of 3D C/SiC composites to niobium alloy, Scripta Materialia, 2006, vol. 55, no. 2, pp. 151–154.

Peteves S.D., Paulasto M., Ceccone G. and Stamos V.: The reactive route to ceramic joining: fabrication, interfacial chemistry and joint properties, Acta Materialia, 1998, vol. 46, no. 7, pp. 2407–2414.

Loehman R.E.: Recent progress in ceramic joining, Key Engineering Materials, 1999, vol. 161–163, no. 2, pp. 657–662.

Fukai T., Naka M. and Schuster J.C.: Interfacial structure and reaction mechanism of SiC/V joints, Transactions of JWRI, 1997, vol. 26, no. 1, pp. 93–98.

Gülpen J.H., Kodentsov A.A. and van Loo F.J.J.: Growth of silicides in Ni-Si and Ni-SiC bulk diffusion couples, Z. Metallkd., 1995, vol. 86, no. 8, pp. 530–539.

Bhanumurthy K., Schmid-Fetzer R.: Interface reactions between silicon carbide and metals (Ni, Cr, Pd, Zr), Composites Part A: Applied Science and Manufacturing, 2001, vol. 32, no. 2, pp. 569–574.

Xiong H.P., Chen B., Kang Y.S., Mao W., Kawasaki A., Okamura H. and Watanabe R.: Wettability of Co-V, and PdNi-Cr-V system alloys on SiC ceramic and interfacial reactions, Scripta Materialia, 2007, vol. 56, no. 2, pp. 173–176.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Xiong, HP., Chen, B., Mao, W. et al. Joining of Cf/SiC Composite With Pd-Co-V Brazing Filler. Weld World 56, 76–80 (2012). https://doi.org/10.1007/BF03321149

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321149