Abstract

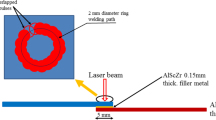

Aluminium alloys have great potential in industrial applications due to their high strength and low weight, specially the AA5xxx and AA6xxx series that have particular applications in the aerospace, military and information technology industries. Laser welding is quite used for joining these materials despite their high reflectivity against laser beam radiation. Nd:YAG lasers are used in pulsed wave mode to overcome a set of difficulties, such as the material absorptivity, its thermal expansion coefficient and thermal conductivity. Autogenous welding of dissimilar aluminium alloys brings additional difficulties due to chemical, thermal and mechanical incompatibility, so the use of a correctly selected filler material improves the compatibility of both alloys being joined. This paper describes the work performed aiming to study laser welding of dissimilar alloys of AA6xxx series and of AA5xxx to AA6xxx series with filler wire. A Nd:YAG laser was used in a pulsed wave mode and a set of filler wires was tested aiming to select the filler presenting better performance. The quality of the welds was evaluated by macro and microstructural analysis. Scanning electron microscopy and hardness measurements were also performed. The results indicate that filler wires with low magnesium and high silicon contents allow for a better weld quality, free of porosity (individual or in clusters). However, the mechanical strength has to be considered in order to assure adequate service performance of the components or structures.

Similar content being viewed by others

References

Cicala E., Duffet G., Andrzejewski H., Grevey D. and Ignat S.: Hot cracking in Al-Mg-Si alloy laser welding — Operating parameters and their effects, Materials Science and Engineering A, 2005, vol. 395, no. 1, pp. 1–9.

Haboudoua A., Peyrea P., Vannes A.B. and Peix G.: Reduction of porosity content generated during Nd:YAG laser welding of A356 and AA5083 aluminium alloys, Materials Science and Engineering A, 2003, vol. 363, no. 1, pp. 40–52.

ASM Handbook, Welding Brazing and Soldering, American Society for Metals (ASM), vol. 6, 2004.

http://www.matweb.com — online resources on Material Property Database, last visited on May 2009.

Technical information, Laser build-up welding in tool and mold making, TRUMPF Laser GmbH + Co. KG Copyright © Novembre de 2007.

Quintino L., Vilaça P. and Gonçalves V: Nd:YAG laser welding of aluminum alloys, Tecnologia & Qualidade, Oct/Dec 2003, vol. 46, 34–36 (in Portuguese).

Paleocrassas A.G.: Feasibility investigation of laser welding aluminum alloy 7075-T6 through the use of a 300 W, Single-mode, ytterbium fiber optic laser, Degree of Master of Science, Graduate Faculty of North Carolina State University, 2005.

ASM Handbook, Metallography and microstructures, American Society for Metals (ASM), vol. 9, 2004.

Prasad Rao K., Ramanaiah N. and Viswanathan N.: Partially melted zone cracking in AA6061 welds, Materials and Design, 2008, vol. 29, no. 1, pp. 179–186.

ASM Handbook, Properties and selection: Nonferrous alloys and special-purpose materials, American Society for Metals (ASM), vol. 2, 2004.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pinto, L.A., Quintino, L., Miranda, R.M. et al. Laser Welding of Dissimilar Aluminium Alloys with Filler Materials. Weld World 54, R333–R341 (2010). https://doi.org/10.1007/BF03266747

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266747