Abstract

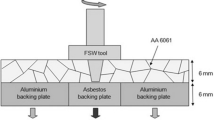

The Boeing Company designed and fabricated a prototype Small Munitions Dispenser (SMD). The SMD’s main structural element is a 7050-T7451 aluminium alloy, box beam. To manufacture it, two, rough machined upper and lower caps are friction stir welded together at opposing 2.5 m long butt joints. The resulting weldment is then machined to the final box beam configuration. The welds pass through the short-transverse grain direction of the plates from which the upper and lower caps were machined. Because Boeing did not have mechanical property data for friction stir welds made in 7050-T7451 plate with this grain orientation, specimens were made that simulated the upper cap to lower cap welds. From these test specimens, coupons were extracted and mechanically tested in transverse and longitudinal tension, single shear, constant amplitude fatigue, and crack growth fatigue. The results show the friction stir welds met all of their design requirements. Base metal and weld metal specimens were corrosion tested. The specimens passed the exfoliation corrosion and stress corrosion cracking tests. Only the base metal and heat-affected zones passed Boeing’s requirements for electrical conductivity and stress corrosion cracking susceptibility factor.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bolser, D., Talwar, R. & Lederich, R. Mechanical and Corrosion Properties of Friction Stir Welded 7050-T7451 Aluminium Alloy. Weld World 49, 27–33 (2005). https://doi.org/10.1007/BF03266472

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266472