Abstract

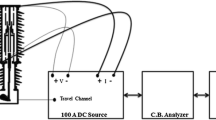

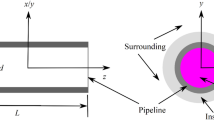

This paper describes an arc sensor system for automatic MAG welding. Based on conventional mathematical models of spray transfer, a new arc sensor model of short-circuiting transfer in the high-speed oscillating (10 Hz–50 Hz) MAG process has been developed. The simulation results of short-circuiting transfer behaviour agree with the experimental results. An optimisation of the oscillating frequency, for the short-circuiting frequency, sustains to improve the sensitivity and reliability of the arc sensor. The arc sensor system based on this principle enables to keep practical accuracy for seam tracking at short-circuiting metal transfer condition, and the automatic welding machine with this sensor was applied to field welding of gas pipelines.

Similar content being viewed by others

References

Sugitani Y.: Automatic pipeline GMA welding technology for high efficiency and intellectualization, IIW doc. XII-1641–00.

Sugitani Y.: Development of Automatic MAG Welding System for Pipeline, SW-1498-83–1983.

Ushio M., Mao W.: Modelling of the arc sensor for DC MIG/MAG welding on open arc mode, Journal of Japan Welding Society, 1996, vol. 14, No. 1 (in Japanese).

Maruo H., Hirata Y.: Wire melting rate in pulsed MIG welding, Journal of Japan Welding Society, 1985, vol. 3, No. 1 (in Japanese).

Ushio M., Mao W.: Dynamic characteristics of arc sensor in GMA welding in dip transfer mode, Journal of Japan Welding Society, 1997, vol. 15, No. 2 (in Japanese).

Xu P.: Circuit simulation for gas metal arc welding, Science and Technology of Welding and Joining, 1999, vol. 4, No. 6.

Lesnewich A.: Control on melting rate and metal transfer in gas shielding metal arc welding, Weld. J., 1958, vol. 37, No. 8.

Halmoy E.: Wire melting rate, droplet temperature, and effective anode melting potential, Conference on arc physics and weld pool behavior in London, 1979.

Lancaster J.F.: The physics of welding, 1986, Oxford Pergamon Press.

Ikuno Y.: Fast automatic welding machine for gas pipelines, IIW doc. XII-1643–00.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kodama, S., Ichiyama, Y., Ikuno, Y. et al. A Mathematical Model of Short-Circuiting Transfer in the High-Speed Oscillating MAG Process Development of Automatic MAG Welding Machine with Arc Sensor and its Application to Field Welding of Gas Pipelines. Weld World 48, 27–34 (2004). https://doi.org/10.1007/BF03266440

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266440