Abstract

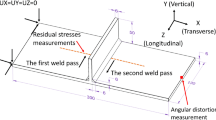

The experiment was carried out using a bead-on-plate specimen with the groove placed to accurately predict welding distortion. The experiment was simulated with thermal elastic-plastic analysis based on FEM. Comparing and investigating both results, the dominant factors for high accuracy prediction of welding distortion were determined. In the thermal elastic-plastic analysis, the yield condition should be satisfied regardless of the magnitude of yield stress of the material. It was not known if the predicted results of welding distortion obtained without satisfying the yield condition in the whole temperature range were overestimated or underestimated. The accuracy of prediction of welding distortion was improved by applying heat input to the weld metal bead shape, not just the groove profile. It was determined that satisfying the yield condition in the entire temperature range and considering the weld metal shape as the deposited metal were the dominant factors for high accuracy prediction of welding distortion.

Similar content being viewed by others

References

Kim Y.-C.: Development of tool for predicting welding distortion with high accuracy, Special Session of JWS, 2003, pp. 21–22 (in Japanese).

Kim Y.-C., Lee J.-Y, Inose K.: The high accurate prediction of welding distortion generated by fillet welding, Quarterly Journal of the Japan Welding Society, 2005, vol. 23, no. 3, pp. 431–435 (in Japanese).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kim, YC., Lee, JY. & Inose, K. Determination of Dominant Factors in High Accuracy Prediction of Welding Distortion. Weld World 54, R234–R240 (2010). https://doi.org/10.1007/BF03263509

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03263509