Abstract

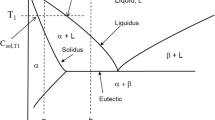

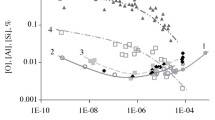

The method of heat generation, heat transfer characteristics, and ingot structure are very different in the VAR and ESR processes, which result in different tendencies and mechanisms for macrosegregation formation in forged IN-718. Freckles are niobium rich and can be generated in both ESR and VAR, with higher incidence in ESR than VAR. White spots are niobium lean and can only be found in VAR-processed materials. Freckles are indige-nous in nature, and result from the flow of solute-rich interdendritic liquid in the mushy zone during solidification. The most plausible cause for white spots is exogenous material, which remains unmelted, falling into the molten pool. The best way to minimize the formation of freckles is to improve the ingot heat transfer rate, a more difficult task in ESR than in VAR.

Similar content being viewed by others

References

J.A. Dominque, K.O. Yu and H.D. Flanders, “Characterization of Macrosegregation in ESR IN-718,” Proceedings of the Symposium on Fundamentals of Alloy Solidification Applied to Industrial Processes, NASA Lewis Research Center, Cleveland, September 12 and 13, 1984, pp. 139–149.

H.L. Eiselstein, “Metallurgy of a Columbium-Hardened Nickel-Chromium-Iron Alloy,” Advances in the Technology of Stainless Steels and Related Alloys, ASTM STP 369, 1965, pp. 62–79.

M.C. Flemings and G.E. Nereo, “Macrosegregation, Part I,” Trans. Met. Soc. AIME, 212, 1967, p. 1449.

M.C. Flemings, G.E. Nereo and R. Mehrabian, “Macrosegregation, Part II,” Trans. Met. Soc. AIME, 242, 1968, p. 41.

M.C. Flemings and G.E. Nereo, “Macrosegregation, Part III,” Trans. Met. Soc. AIME, 242, 1968, p. 50.

R. Mehrabian, M. Keane and M.C. Flemings, “Interdendritic Fluid Flow and Macrosegregation: Influence of Gravity,” Met. Trans., 1, 1970, p. 1029.

R. Mehrabian, M.A. Keane and M.C. Flemings, “Experiments on Macrosegregation and Freckle Formation,” Met. Trans., 1, 1970, pp. 3238–3241.

R. Mehrabian and M.C. Flemings, Trans. Met. Soc. AIME, 245, 1969, p. 2347.

T. Fujii, D.R. Poirer and M.C. Flemings, “Macrosegregation in a Multicomponent Low Alloy Steel,” Met. Trans. B., 10B, 1979, p. 331.

C.L. Jeanfils, J.H. Chen and H.J. Klein, “Modeling of Macrosegregation in Electroslag Remelting of Superalloys,” Superalloys 1980, p. 119, Tien et. al., Eds., ASM, Metals Park, OH, 1980.

S. Kou, D.R. Poirer and M.C. Flemings, “Macrosegregation in Rotated Remelted Ingots,” Met. Trans. B, 1978, p. 711.

S. Kou, D.R. Poirer and M.C. Flemings, “Macrosegregation in Electroslag Remelted Ingots,” Electric Furnace Proceedings, 1977, 35, p. 221.

S.D. Ridder, F.C. Reyes, S. Chakravorty, R. Mehrabian, J.D. Nauman, J.H. Chen and H.J. Klein, “Steady State Segregation and Heat Flow in ESR,” Met. Trans. B, 9B, 1978, p. 415.

S. Kou, “Macrosegregation in Electroslag Remelted Ingots,” Ph.D. Thesis, MIT, February 1978.

K.O. Yu and H.D. Flanders, “Comparison of ESR-VAR Processes: Part II. Melting Phenomena and Ingot Structure,” Proc. Vac. Met. Conf. on Specialty Metals Melting and Processing, Pittsburgh, PA, June 11–13, 1984, pp. 107–118, Bhat and Lherbier, Eds., Iron and Steel Soc., 1985.

R. Mehrabian, “Relationship of Heat Flow to Structure in Rapid Solidification Processing” Proc. Int. Conf. on Rapid Solidification Processing, Reston, VA., November 13–16, 1977, pp. 9–27, Mehrabian et. al., Eds., Baton Rouge, Claitor’s Publishing Div.

K.O. Yu, C.B. Adasczik and W.H. Sutton, “Heat Transfer Characteristics in an Industrial Scale ESR System,” Proc. of the 7th Int. Conf. on Vac. Met. (ICVM), November 1982, Japan, pp. 1495–1501.

K.O. Yu, “The Influences of P_l Profile and Grain Growth Pattern on Dendrite Structure of ESR and VAR Ingots,” submitted to Met. Trans. B.

K.O. Yu, “Comparison of ESR-VAR Processes: Part I. Heat Transfer Characteristics of Crucible,” Proc. 1984 Vac. Met. Conf. on Specialty Metals Melting and Processing, Pittsburgh, PA, June 11–13, 1984, pp. 83–92. Bhat and Lherbier, Eds., Iron and Steel Soc, 1985.

K.O. Yu et. al., “Summary Report of Technical Department 718 White Spot Meeting,” SMC Internal Memo, August 20, 1982.

J.F. Wadier, G. Raisson and J. Morlet, “A Mechanism for White Spot Formation in Remelted Ingots,” Proc. Vac. Met. Conf. on Specialty Metals Melting and Processing, Pittsburgh, PA, June 11–13, 1984, pp. 119–126, Bhat and Lherbier, Eds., Iron and Steel Soc., 1985.

Additional information

K.O. Yu received his Ph.D. in metallurgical engineering from the University of Kentucky in 1978. He is currently a Senior Process Modeling Engineer at Special Metals Corporation, New Hartford, New York. Dr. Yu is also a member of TMS.

John A. Domingue received his Ph.D. in physical chemistry from Syracuse University in 1977. He is currently Senior Engineer, Process Metallurgy, Special Metals Corp., New Hartford, New York.

G.E. Maurer received his Ph.D. in materials engineering from Rensselaer Polytechnic Institute. He is currently the Director of Re-search and Development at Special Metals Corporation, New Hartford, New York.

H.D. Flanders, Jr. graduated from the Academy of Aeronautics in 1954. He has been active in primary and secondary melting at Special Metals Corporation for the last 30 years.

Rights and permissions

About this article

Cite this article

Yu, K.O., Domingue, J.A., Maurer, G.E. et al. Macrosegregation in ESR and VAR Processes. JOM 38, 46–50 (1986). https://doi.org/10.1007/BF03257955

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03257955