Abstract

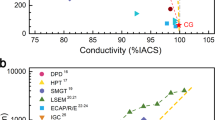

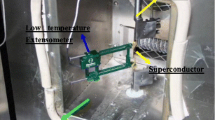

The metallic precursor process, used in the production of high-temperature superconducting ceramics, exploits the relatively high formability of the metallic state to fabricate multifilament wires with excellent transport and mechanical properties. Multifilament wires, containing 9,583 filaments, exceed by tenfold the filament counts achieved by any other process. Oxide critical current densities of 17.7 kA/cm2 at 77 K in self-field surpass the best electrical performance reported for any other process used to fabricate multifilament composite wires. The mechanical properties of these wires approach the behavior of ideal composites, resulting in the flexibility, durability, and strain tolerance required for large-scale use in power generation, distribution, and end-use applications such as motors and current limiters.

Similar content being viewed by others

References

H. Kumakura, K. Togano, and H. Maeda, Stud. High Temp. Supercond., 7 (1991), pp. 1–21.

J.L. Tallon et al., Nature, 333 (1988), p. 153.

K.H. Sandhage et al., “The Metallic Precursor Approach to Long Lengths of YBa2Cu3O7−x Superconducting Wire,” High Temperature Superconducting Compounds III, ed. S.H. Wang, A. DasGupta, and E. Collings (Warrendale, PA: TMS, 1991), pp. 347–362.

A. Otto et al., “Multifilamentary Bi-2223 Composite Tapes Made by a Metallic Precursor Route:” IEEE Trans. Appl. Supercon., 3 (1) (1993), pp. 915–922.

K.H. Sandhage, G.N. Riley, Jr., and W.L. Carter, “Critical Issues in the OPIT Processing of High-Jc BSCCO Superconductors,” JOM, 43 (March 1991), pp. 21–25.

P. Haldar and L. Motowidlo, “Processing High Critical Current Density Bi-2223 Wires and Tapes,” JOM (October 1992), pp. 54–58.

K. Sato et al., “Development of Silver Sheathed Bismuth Superconducting Wires and Their Application,” J. Appl. Phys., 70 (10, 15 November 1991), pp. 6484–6488.

Q. Li et al., “Thermomechanical Processing of Ag-Sheathed Bi-2223 Tapes” (Paper presented at the Materials Research Society Conference, Boston, MA, 30 November–4 December 1992).

Y. Yamada et al., “Microstructure and Superconducting Properties of Ag-Sheathed (Bi,Pb)2Sr2Ca2Cu3Ox Tapes” (Paper presented at the Fifth International Symposium on Superconductivity ISS’92, Kobe, Japan, 16–19 November 1992).

H. Yamasaki et al., “Critical Current Density in High-Quality Bi2Sr2Ca2Cu3Ox Thin Films Prepared by Metalorganic Chemical-Vapor Deposition,” J. Appl. Phys. 72 (7) (1992), pp. 2951–2957.

A.P. Malozemoff et al., “Progress in the Development of Bismuth-Based High Temperature Superconducting Tapes,” Cryogenics, 32 (ICMC supplement) (1992), pp. 478–484.

H. Mukai et al., “Multifilamentary Bismuth (2223) Multilayer-Wound Conductors for Power Transmission Lines” (Paper presented at the Materials Research Society Conference, San Francisco, CA, 27 April–1 May 1992).

W. Gao and J.B. Vander Sande, “Textured BSCCO/Ag Superconducting Microcomposites with Improved Critical Current Density Through Mechanical Deformation,” Supercond. Sci. Technol., 5 (1992), pp. 316–328.

A. Otto, R. Kontra, and J.B. Vander Sande, “Superconducting Oxide Formation in the Yb-Ba-Cu-O System,” Physica C 190 (1992), pp. 581–596.

A. Otto, “The Oxidation Formation and Properties of YbnBa2nCu3n+1Ox [n=1,2,∞] J Superconducting Oxide—Silver Composites,” Ph.D. thesis, Massachusetts Institute of Technology (1991), pp. 25–108.

R. Kontra, “An Electron Microscopy Study of Phase Transformations in Yb-Ba-Cu-O Superconductors,” D.Sc. thesis, Massachusetts Institute of Technology (1992), pp. 16–167.

K.H. Sandhage, “The Preparation of Superconducting YBa2Cu3O7−y/Ag Microlaminates by an Oscillating Oxidation Scheme,” J. Electrochem. Soc., 139 (6) (1992), pp. 1661–1671.

J.S. Benjamin, “Dispersion Strengthened Superalloys by Mechanically Alloying,” Met. Trans., 1 (1970), pp. 2943–2951.

R.A. Outlaw et al., “Oxygen Transport through High-Purity, Large-Grain Ag,” J. Mater. Res., 3 (6) (1988), pp. 1378–1384.

G.N. Riley and W.L. Carter, “Recent Progress of OPIT-Processed Composite Wires,” Am. Cer. Soc. Bull., 72 (7) (1993), pp. 91–97.

M.P. Maley et al., “Behavior of Critical Currents in Bi-Pb-Sr-Ca-Cu-O/Ag Tapes from Transport and from Magnetization Measurements: Dependence upon Temperature, Magnetic Field and Field Orientation,” Phys. Rev. B, 143 (45) (1992), pp. 7566–7569.

L. Civale et al., “Superconducting Current Density Enhancement by Heavy Ion Irradiation of Bi-2223 Silver Clad Tapes,” Physica C, 208 (1993), pp. 137–142.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Otto, A., Craven, C., Daly, D. et al. Properties of high-Tc wires made by the metallic precursor process. JOM 45, 48–52 (1993). https://doi.org/10.1007/BF03222435

Issue Date:

DOI: https://doi.org/10.1007/BF03222435