Abstract

This paper introduces modeling and simulation results for pipeline inspection gauge (PIG) with bypass flow control in natural gas pipeline. The dynamic behaviour of the PIG depends on the different pressure across its body and the bypass flow through it. The system dynamics includes: dynamics of driving gas flow behind the PIG, dynamics of expelled gas in front of the PIG, dynamics of bypass flow, and dynamics of the PIG. The bypass flow across the PIG is treated as incompressible flow with the assumption of its Mach number smaller than 0.45. The governing nonlinear hyperbolic partial differential equations for unsteady gas flows are solved by method of characteristics (MOC) with the regular rectangular grid under appropriate initial and boundary conditions. The Runge-Kuta method is used for solving the steady flow equations to get initial flow values and the dynamic equation of the PIG. The sampling time and distance are chosen under Courant-Friedrich-Lewy (CFL) restriction. The simulation is performed with a pipeline segment in the Korea Gas Corporation (KOGAS) low pressure system, Ueijungboo-Sangye line. Simulation results show us that the derived mathematical model and the proposed computational scheme are effective for estimating the position and velocity of the PIG with bypass flow under given operational conditions of pipeline.

Similar content being viewed by others

Abbreviations

- A :

-

Pipe cross section [m2]

- c :

-

Wave speed [m/s]

- C :

-

Linear damping coefficient of the PIG [Ns/m]

- C c :

-

Convection heat transfer coefficient [W/m2K]

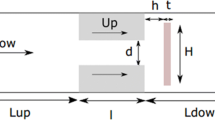

- d :

-

Internal diameter of pipe [m]

- d valve :

-

Bypass valve diameter [m]

- F b :

-

Braking force [N]

- F f :

-

Friction force per unit pipe length [N/m]

- F fp :

-

Friction force between the PIG and pipeline’s wall including [N]

- −F fpsta :

-

Static friction force

- −F fpdyn :

-

Dynamic friction force

- F p :

-

The PIG driving force [N]

- h :

-

The opening height of valve [m]

- k :

-

Pipe wall roughness [m]

- K :

-

Wear factor per distance travel [N/m]

- K SC :

-

Sudden constraction loss coefficient

- K SE :

-

Sudden expansion loss coefficient

- K total :

-

Total loss coefficient

- L PIG :

-

Length of the PIG [m]

- m :

-

Hydraulic mean radius of pipe [m]

- M :

-

Weight of the PIG [kg]

- p :

-

Flow pressure [N/m2]

- q :

-

Compound rate of heat inflow per unit area of pipe wall [W/m2]

- S :

-

Perimeter of pipe [m]

- T :

-

Flow temperature [K]

- T ext :

-

Seabed temperature [K]

- u :

-

Flow velocity [m/s]

- u V :

-

Flow velocity through valve [m/s]

- v PIG :

-

Velocity of the PIG [m/s]

- x :

-

Distance from pipe inlet [m]

- x PIG :

-

Position of the PIG [m]

- X :

-

Denote flow parameter values

- γ:

-

The ratio of specific heat

- ν:

-

Kinetic viscosity of flow [m2/s]

- ϱ:

-

Flow density [kg/m3]

- L, R, M, N, S, O, P :

-

Denote the grid points, and

- 0, l :

-

Denote the points at inlet and outlet of pipeline

References

Azevedo, L. F. A., Braga, A. M. B., Nieckele, A. O., Naccache, M. F. and Gomes, M. G. F. M., 1996, “Simple Hydrodynamic Models for the Prediction of Pig Motions in Pipelines,” inProceedings of the 1996 Offshore Technology Conference, TX., USA, pp. 729–739.

Cordell, Jim and Vanzant, Hershel, 1999, “All About Pigging,” On-Stream Systems Limited and Hershel Vanzant & Associates.

Fox, J. A., 1977,Hydraulic Analysis of Unsteady Flow in Pipe Networks, John Wiley & Sons Pub.

Korea Gas Corporation, 2000, “The First Stage of Development of Intelligent PIG for Low Pressure Pipeline.”

Lima, P. C. R., Petrobas, S. A., and Yeoung, H., 1999, “Modeling of Pigging Operations,” inProceedings of SPE Annual Technical Conference and Exhibition, pp. 563–578, TX., USA.

Nguyen, T. T., Yoo, H. R., Rho, Y. W., and Kim, S. B., 2000, “Modelling and Simulation for PIG Flow Control in Natural Gas Pipeline,” inProceedings of the 15th Korea Automatic Control Conference, pp. 448–451, Yong-in, Korea.

Nguyen, T. T., Yoo, H. R., Rho, Y. W., and Kim, S. B., 2001, “Modelling and Simulation for PIG Flow Control in Natural Gas Pipeline,”KSME International Journal, Vol. 15, No. 8, pp. 1165–1173.

Out, J. M. M., 1993, “On the Dynamics of Pigslug Trains in Gas Pipeline,” OMAE, Vol. V,Pipeline Technology, ASME, pp. 395–403.

Sim, W. G. and Park, J. H., 1997, “Transient Analysis for Compressible Fluid Flow in Transmission Line by the Method Of Characteristics,”KSME International Journal, Vol. 11. No. 2, pp. 173–185.

Smith, G. L., 1992, “Pigging Velocities and the Variable-Speed PIG,”Proceedings of Pipeline Pigging and Integrity Monitoring Conference, Amsterdam, Netherlands, 28th September-2nd.

Tannehill, John C., Anderson, Dale A. and Pletcher, Richard H., 1997, “Computational Fluid Mechanics and Heat Transfer,” Taylor & Francis Pub.

White, Frank M., 1999,Fluid Mechanics, McGraw-Hill Pub.

Willson, D. J. and Yokota, J. W., 1994, “Speed Control Research and Development,” Nowsco Pipeline Service.

Wylie, E. Benjamin, Streeter, Victor L. and Suo, Lisheng 1993,Fluid Transients in Systems, Prentice-Hall, Inc.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nguyen, T.T., Kim, S.B., Yoo, H.R. et al. Modeling and simulation for PIG with bypass flow control in natural gas pipeline. KSME International Journal 15, 1302–1310 (2001). https://doi.org/10.1007/BF03185671

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03185671