Abstract

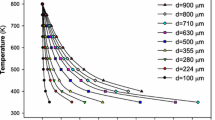

Droplets of Ag60Sb34Cu6 ternary alloy within the diameter range of 60–800 μm were rapidly solidified by means of drop tube containerless processing, and the solidification mechanism is analyzed. With a decrease in droplet size, the cooling rate increases from 57 to 5.8×104 K/s. The maximum undercooling is determined to be 180 K (0.23T L) and the microstructure of primary ε(Ag3Sb) dendrite refines drastically until homogenous equiaxed dendrite forms. Experimental results indicate that (ε+Ag) pseudobinary eutectic cannot form under high undercooling conditions and the solubility of Ag in primary ε phase increases as undercooling increases. Based on thermal analysis and crystal growth morphology, it is found that this alloy is solidified in two ways corresponding to different undercooling levels.

Similar content being viewed by others

References

Plapp, M., Karma, A., Eutectic colony formation: A phase-field study. Phys Rev E, 2002, 66: 061608–061624.

Hawksworth, A., Rainforth, W. M., Jones, H., A novel microstructure in the Al-La-Ni ternary eutectic alloy, Scripta Materialia, 1998, 39: 1371–1376.

Ingerly, D. B., Swenson, D., Jan, C. H. et al., Phase equilibria of the Ga-Ni-As ternary system, J. Appl. Phys., 1996, 80: 543–550.

Akamatsu, S., Faivre, G., Traveling waves, two-phase fingers, and eutectic colonies in thin-sample directional solidification of a ternary eutectic alloy, Phys. Rev. E, 2000, 61: 3757–3770.

Takahashi, M., Shoji, H., Kadowaki, S. et al., Saturation magnetization and uniaxial magnetocrystalline anisotropy for Co-based binary and Co-Ge-Cr ternary alloys, Appl. Phys. Lett., 2000, 76: 3457–3459.

Mansour, A. N., Marcelli, A., Cibin, G. et al., Amorphous Al90Fe x Ce10−x alloys: X-ray absorption analysis of the Al, Fe and Ce local atomic and electronic structures, Phys. Rev. B, 2002, 65: 134207–134214.

McCormack, M., Kammlott, G. W., Chen, H. S. et al., Significantly improved mechanical properties in Pb-free, Sn-Zn-In solder alloy by Ag doping, Appl. Phys. Lett., 1994, 65: 1100–1102.

Dutta, B., Rettenmayr, M., Effect of cooling rate on the solidification behavior of Al-Fe-Si alloys, Mater. Sci. Eng., 2000, 283A: 218–224.

Wang, N., Wei, B., Containerless rapid solidification of Ag28.1Cu41.4Ge30.5 ternary alloy, J. Alloy Comp., 2000, 302: 274–280.

Wang, H. P., Cao, C. D., Wei, B., Rapid monotectic solidification during free fall in a drop tube, Chin. Sci. Bull., 2004, 49: 220–224.

Yao, W. J., Han, X. J., Wei B. High undercooling and rapid dendritic growth of Cu-Sb alloy in drop tube, Chin. Sci. Bull., 2002, 47: 1312–1316.

Cao, C. D., Lu, X. Y., Wei, B., Peritectic solidification under high undercooling condition, Chin. Sci. Bull., 1999, 44: 1338–1343.

Dutkiewicz, J., Massalski, T. B., Search for metallic glasses at eutectic compositions in the Ag-Cu-Ge, Ag-Cu-Sb and Ag-Cu-Sb-Ge systems, Metall Trans. A, 1981, 12A: 773–778.

Rogers, J. R., Davis, R. H., Modeling of collision and coalescense of droplets during microgravity processing of Zn-Bi immiscible alloys, Metall Trans. A, 1990, 21A: 59–68.

Lee, E., Ahn, S., Solidification process and heat transfer analysis of gas-atomized alloy droplets during spray forming, Acta Metall Mater., 1994, 42: 3231–3243.

Author information

Authors and Affiliations

About this article

Cite this article

Ruan, Y., Wang, N., Cao, C. et al. Rapid solidification mechanism of Ag60Sb34Cu6 ternary alloy in drop tube. Chin.Sci.Bull. 49, 1801–1805 (2004). https://doi.org/10.1007/BF03183403

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF03183403