Abstract

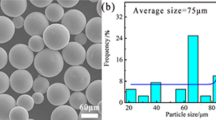

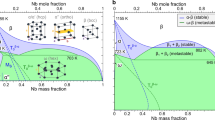

To determine the optimum method of producing TiAl intermetallic compounds with an oriented lamellar microstructure the authors applied reactive diffusion and high-temperature deformation in a two-phase state on Ti-43 mol.%Al and Ti-46 mol.%Al. The reactive diffusion process produces an α single-phase state with orientations that reflect the texture of the starting titanium foils; the high-temperature deformation aims to rotate the lamellar interface by means of preferential activation of the crystal slip systems that are parallel to the interface. The reactive diffusion process can effectively control the texture in an α single-phase state, though many voids are formed at the initial stages of reactive diffusion. Furthermore, after the heating process for the construction of the lamellar microstructure, uniaxial compression at 1323 K is quite effective for ensuring that the lamellar interface is rotated parallel to the compression plane. Finally, the deformation causes about one half of all the lamellae to be arranged within 20 degrees of the compression plane.

Similar content being viewed by others

References

H. Inui, M. H. Oh, N. Nakamura, and M. Yamaguchi,Acta matel.,40, 3095–3104 (1992).

S. Yokoshima and M. Yamaguchi,Acta matel.,44, 873–883 (1996).

D. R. Jonson, H. Inui, and M. Yamaguchi,Acta Mater.,44, 2523–2535 (1996).

H. A. Lipsitt, D. Shechtman, and R. E. Schafric,Metall. Trans. A,6, 1991 (1975).

S. M. Sastry and H. A. Lipsitt,Proceedings of the 4 th International Conference of Titanium, p. 1231, AIME (1981).

K. S. Park, K. Matsumura, and H. Fukutomi,J. Jpn Inst. Met.,66, 425–430 (2002).

H. Fukutomi, K. S. Park, T. Iseki, and T. Takahashi,Materials Science Forum,426, 1703–1708 (2003).

A. Nomoto and H. Fukutomi,J. Jpn. Inst. Met.,61, 378–384 (1977).

H. Fukutomi, A. Nomoto, and T. Ota,Trans. JIM,36, 610 (1995).

Y. W. Kim,Acta metal. mater.,40, 1121 (1992).

H. Fukutomi, M. Ueno, M. Nakamura, T. Suzuki, and S. Kikuchi,Mat. Trans. JIM 40, 654–658 (1999).

T. B. Massalski, H. Okamoto, P. R. Subramanian, and L. Kacprzak, Binary Alloy Phase Diagrams Second Edition CD-ROM, ASM (1990).

M. J. Blackbum,Science, Technology and Application of Titanium (eds., R. T. Jaffee and N. E. Promisel), p. 633, Pergamon Press, London (1979).

M. Dahams and H. J. Bunge,J. Appl. Cryst.,22, 439–444 (1989).

K. S. Park, D. S. Bae, G. H. Lee, and S. K. Lee,Met. Mater.-Int. 11, 481–486 (2005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, K.S., Bae, D.S., Kim, H.J. et al. Deformation behavior of TiAl intermetallic compounds and orientation control by reactive diffusion and high-temperature uniaxial compression deformation. Met. Mater. Int. 12, 447–451 (2006). https://doi.org/10.1007/BF03027713

Issue Date:

DOI: https://doi.org/10.1007/BF03027713