Abstract

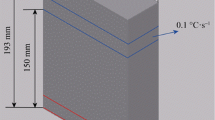

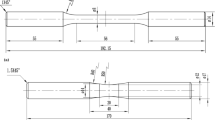

Rotating-bending uniaxial fatigue tests and micro-fatigue crack initiation tests were carried out using a permanent mold cast (PMC) and semi-solid die cast (SDC) with Al−7%Si−0.35%Mg composition in order to examine the relationship between solidification structures and fatigue behaviors. The crack length was measured using a replication method. Fatigue strength was improved in SDC, which was almost consistent with the predicted fatigue strength using the size of Si particle cluster. Resistance to fatigue crack initiation and fatigue strength were improved in SDC owing to the finer Si cluster and to higher ultimate tensile strength. Fatigue crack in PMC was preferentially initiated at pores. For SDC, the fatigue crack was initiated at the Si particle/matrix interface, and then sucessively grew along eutectic cell boundaries.

Similar content being viewed by others

References

T. Reinhart,ASTM Handbook 19, 813 (1996).

I. J. Polmear,Light Alloys, Metallurgy of the Light Metals, 2nd Ed., p. 144, Edward Arnold, London (1989).

J. Allison, J. Jones, M. Caton, and J. Boileau,Proc. of the 7th Int. Fatigue Congress: Fatigue 99 (eds. X. R. Wu and Z. G. Wang), vol. 3, p. 2021, Beijing, P.R. China (1999).

M. Kubota, Y. Ochi, and R. Shibata,Proc. 93rd Conf. of Jpn. Inst. Light Met., p. 307, Jpn. Inst. Light Met. (1999).

S. Kumai, S. Aoki, S. W. Han, and A. Sato,Mater. Trans JIM 40, 685 (1999).

K. Gall, N. Yark, M. Horstemeyer, D. L. Madowell, and J. Fan,Metall. Mater. Trans. A 30, 3079 (1999).

K. Gall, N. Yark, M. Horstemeyer, D. L. Madowell, and J. Fan,Mech. Mater. 32, 265 (2000).

Y. Kuroki, T. Tanaka, T. Sato, and A. Kamio,J. Jpn. Inst. Light Met. 50, 116 (2000).

M. J. Couper, A. E. Neeson, and J. R. Griffiths,Fatigue Fract. Eng. Mater. Struct. 13, 213 (1990).

J. C. Ting and F. V. Lawrence,Fatigue Fract. Eng. Mater. Struct. 16, 631 (1993).

B. Skallerud, T. Iveland, and Harkegard,Eng. Fract. Mech. 44, 857 (1993).

M. Kobayashi and T. Matsui,Trans. Jpn. Soc. Mech. Eng. A 62, 341 (1996).

Y. Murakami, M. Kobayashi, T. Makino, T. Toriyama, Y. Kurihara, S. Takasaki, and R. Ebara,Trans. Jpn. Soc. Mech. Eng. A 57, 2305 (1991).

E. J. Gumbel,Statistics of Extremes, p. 34, Columbia Univ. Press. (1957).

M. Kubota, Y. Ochi, A. Ishii, and S. Shibata,Trans. Jpn. Soc. Mech. Eng. A 61, 2342 (1995).

K. Shiozawa, Y. Tohda, and S. M. Sun,Fatigue Fract. Eng. Mater. Struct. 20, 237 (1997).

S. W. Han, S. Kumai, and A. Sato,Mater. Sci. Eng. A 332, 56 (2002).

J. Lankford,Fatigue Fract. Eng. Mater. Struct. 8, 161 (1985).

J. Lankford,Fatigue of Eng. Mater. Struct. 5, 233 (1982).

K. J. Miller,Fatigue of Eng. Mater. Struct. 5, 223 (1982).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Han, SW., Lee, UJ. & Kim, SW. Effects of solidification structure on fatigue crack initiation and fatigue strength in Al−Si−Mg cast alloys. Met. Mater. Int. 8, 443–447 (2002). https://doi.org/10.1007/BF03027240

Issue Date:

DOI: https://doi.org/10.1007/BF03027240