Abstract

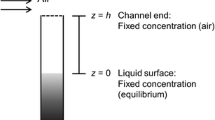

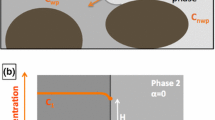

A mass balance error-free numerical procedure for simulation of multicomponent and multi-layered phase diffusional reactions has been suggested, based on an explicit fixed grid finite difference method. Basically, a local equilibrium was assumed at each phase interface and one dimensional movement of interfaces was considered. Attention was paid to the treatments of newly formed thin phase layers and different molar volumes among interacting phases, together with the removal of a mass balance error. Specially derived finite difference forms were used to treat phase layers thinner than two inter-grid distances. A new flux balance equation which is independent from the molar volume differences among phases and leaves no mass balance error was developed by a transformation of space variable system and by a systematic analysis of sources of mass balance error, respectively. Through some model simulations, it could be shown that the present numerical procedure cantreat multi-layered phase diffusion including thin layered phases and can reproduce transitions of layer sequences during diffusional reactions successfully, leaving no mass balance error.

Similar content being viewed by others

References

B.-J. Lee and K. H. Oh,Z. Metallkd. 87, 95 (1996).

S. Crusius, G. Inden, U. Knoop, L. Hoglund and J. Ågren,Z. Metallkd. 83, 673 (1992).

S. K. Kim, N. J. Kim, G. Shin and C. H. Lee,J. Kor. Inst. Met. & Mater. 33, 1144 (1995).

A. J. Hickl and R. W. Heckel,Metall. Trans. 6A, 431 (1975).

J. Crank,The Mathematics of Diffusion, Clarendon Press, Oxford (1975).

Y. Zhou and T. H. North,Modelling Simul. Mater. Sci. Eng. 1, 505 (1993).

L. Kaufman and H. Bernstein,Computer Calculation of Phase Diagrams, Academic Press, New York (1970).

B.-J. Lee, N. M. Hwang and H. M. Lee,Acta mater. 45, 1867 (1997).

B.-J. Lee,Acta mater. 45, 3993 (1997).

B.-J. Lee,Scripta mater. 38, 499 (1998).

B.-J. Lee,J. Kor. Inst. Met. & Mater. 31, 480 (1993).

J.-O. Andersson and J. Agren,J. Appl. Phys. 72, 1350 (1992).

J. Fridberg, L.-E. Torndahl and M. Hillert,Jernkont. Ann. 153, 263 (1969).

B.-J. Lee,Proceedings of the 6 th Symposium on Phase Transformation (eds., S.-K. Hwang, J.-K. Park and J.-S. Lee), p. 67, Kor. Inst. Met. & Mater., Korea (1996).

J. S. Bae, J. R. Soh, S. K. Kim, Y. D. Lee and H. M. Lee,J. Kor. Inst. Met. & Mater. 36, 402 (1998).

H. M. Lee, J. S. Bae, J. R. Soh, S. K. Kim and Y. D. Lee,Mater. Trans. JIM 39, 633 (1998).

J.-O. Andersson, L. Höglund, B. Jönsson and J. Ågren, inFundamentals and Applications of Ternary Diffusion (ed., G. R. Purdy), p. 153, Pergamon Press, New York (1990).

P. Nash (Ed.),Phase Diagrams of Binary Nickel Alloys, ASM International, Materials Park, OH (1991).

L. S. Castleman and L. L Seigle,Trans. TMS-AIME 212, 589 (1958).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, BJ. Numerical procedure for simulation of multicomponent and multi-layered phase diffusion. Metals and Materials 5, 1–15 (1999). https://doi.org/10.1007/BF03025998

Issue Date:

DOI: https://doi.org/10.1007/BF03025998