Abstract

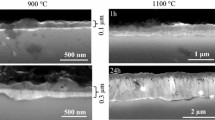

The susceptibilities to stress corrosion cracking (SCC) were investigated using the constant-potential U-bend SCC test. U-bend SCC evaluations were conducted on two iron aluminide compositions based on Fe3Al and containing 2 and 5 at.% Cr in acid-chloride (pH = 4200 ppm Cl), thiosulfate, and tetrathionate solutions at the freely-corroding conditions. Cracking failures occurred in the thiosulfate and tetrathionate solutions, but not in the acid-chloride solution. The iron aluminides were very susceptible to the sulfur-bearing environments in terms of SCC and aqueous corrosion characteristics. To investigate the effect of applied potential on the cracking behavior, U-bend tests were conducted in the acid-chloride solution at an anodic pitting potential and at cathodic hydrogen-evolution potentials. Cracking occurred within 200 h only at the highly negative cathodic potentials and only for the lower Cr composition. These results indicated that two iron aluminides investigated are susceptible to SCC in acid-chloride solution if the corrosion potential is sufficiently active to generate hydrogen, that the cracking mechanism was related to hydrogen embrittlement. The resistance to hydrogen embrittlement cracking increased with increasing Cr content, i.e., higher Cr levels were beneficial in minimizing this form of cracking. Increased resistance to cracking for the U-bend specimens is influenced by the chemical composition of the passive film. Metallographic examinations by scanning electron microscopy revealed that increasing Cr content decreased the proportion of transgranular cleavage cracking and increased the proportion of intergranular cracking.

Similar content being viewed by others

References

S. J. Dapkunas, inFossil Energy Advanced Research and Technology Development, Materials Program, Semiannual Progress Report For the Period Ending (eds., R. R. Judkins and D. N. Braski), p. 439, ORNL/FMP-90/2 (1990).

J. H. Devan, inOxidation of High-Temperature In-termetallics (eds., T. Grobstein and J. Doychak), p. 107, TMS, Warrendale, PA (1989).

S. A. David, J. A. Horton and C. G. McKamey,Welding J. 68, 372 (1989).

C. G. McKamey,in Fossil Energy Advanced Research and Technology Development, Materials Program, Proc. 4th Annual Conf. Fossil Energy Materials (eds., R. R. Judkins and D. N. Braski), p. 197, ORNL/FMP-90/1 (1990).

N. S. Stoloff, M. Shea and A. Castagna, inEnvironmental Effects on Advanced Materials (eds., R. H. Jones and R. E. Ricker), p. 3, TMS, Warrendale, PA (1991).

J. G. Kim and R. A. Buchanan,Corrosion 50, 658 (1994).

S. W. Ciaraldi, inHydrogen Embrittlement: Prevention and Control, STP 962 (ed., L. Raymond), p. 200, ASTM, Philadelphia, PA (1988).

R. C. Newman,Corr. 39, 386 (1983).

R. Bandy,Corr. 39, 391 (1983).

M. L. Saraf,Corr. 37, 412 (1981).

ASTM Standards Making and Using U-Bend Stress Corrosion Test Specimens, ASTM G30.

R. C. Newman and K. Sieradzki,Corr. Sci. 23, 363 (1983).

P. H. Berge,Nuclear Technology 55, 88 (1981).

B. A. Forster,The Acid Rain Debate, p. 12, Iowa State Univ. Press, Ames, IA (1993).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, JG. Stress corrosion cracking susceptibilities of Fe3Al-based iron aluminides. Metals and Materials 1, 133–141 (1995). https://doi.org/10.1007/BF03025924

Issue Date:

DOI: https://doi.org/10.1007/BF03025924