Abstract

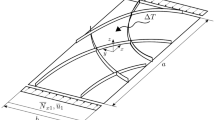

A parametric study of the factors controlling static and dynamic denting, as well as local stiffness, has been made on simplified panels of different sizes, curvatures, thicknesses and strengths. Analyses have been performed using the finite element method to predict dent resistance and panel stiffness. A parametric approach is used with finite element models of simplified panels. Two sizes of panels with square plan dimensions and a wide range of curvatures are analysed for several combinations of material thickness and strength, all representative of automotive closure panels. Analysis was performed using the implicit finite element code, LS-NIKE, and the explicit dynamic code, LS-DYNA for the static and dynamic cases, respectively. Panel dent resistance and stiffness behaviour are shown to be complex phenomena and strongly interrelated. Factors favouring improved dent resistance include increased yield strength and panel thickness. Panel stiffness also increases with thickness and with higher curvatures but decreases with size and very low curvatures. Conditions for best dynamic and static dent performance are shown to be inherently in conflict ; that is, panels with low stiffness tend to perform well under impact loading but demonstrate inferior static dent performance. Stiffer panels are prone to larger dynamic dents due to higher contact forces but exhibit good static performance through increased resistance to oil canning.

Similar content being viewed by others

References

Belytschko, T., Lin, J. I. and Tsay, C., 1984, “Explicit Algorithms for the Non-Linear Dynamics of Shells,”Computer Methods in Applied Mechanics and Engineering, Vol.42, pp.225–251.

Belytschko, T. and Tsay, C., 1983, “A Stabilization Procedure for the Quadrilateral Plate Element with One-Point Quadrature,”International Journal for Numerical Methods in Engineering, Vol. 19, pp. 405–419.

Burley, C. E., Niemeier, B. A. and Koch, G. P., 1976, “Dynamic Denting of Autobody Panels,”SAE Technical Paper No. 760165.

Burley, C. E. and Niemeier, B. A., 1977, “Denting Properties of Aluminum Autobody Components,”SAE Technical Paper No. 770199.

DiCello, J. A. and George, R. A., 1974, “Design Criteria for the Dent Resistance of Auto Body Panels,”SAE Technical Paper No. 740081.

Ekstrand, G. and Asnafi, N., 1998, “On Testing of the Stiffness and the Dent Resistance of Autobody Panels,”Materials and Design 19.

Halquist, J. O., 1996, “LS-NIKE3D User’s Manual,”LSTC Report 1016, Livermore Software Technology Corporation, Livermore, CA.

Halquist, J. O., 1995, “LS-DYNA3D User’s 2020

Manual,”LSTC Report 1082, Livermore Software Technology Corporation, Livermore, CA.

Johnson, T.E. and Schaffnit, W.O., 1973, “Dent Resistance of Cold-Rolled Low-Carbon Steel Sheet,”SAE Technical Paper No. 730528.

Jung, D.W., 2002, “A Parametric Study of Sheet Metal Denting Using a Simplified Design Approach,”KSME International Journal, Vol. 16, No. 12, pp. 1479–1492.

Kohmura, S. and Urbanek, J., 1977, “Dent Resistance of Aluminum Alloy Sheets,” Alcan International Ltd., KRDC Report, KR-77/044.

Mahmood, H. F., 1981, “Dent Resistance of Surface Panel and Slam Area,”SAE Technical Paper No. 810099.

Neimeier, B. A. and Burley, C. E., 1978, “Hailstone Response of Body Panels — Real and Simulated,”SAE Technical Paper No. 780398.

Rolf, R. L., Sharp, M. L. and Stroebel, H. H., 1976, “Structural Characteristics of Aluminum Body Sheet,”SAE Technical Paper No. 770200.

Shi, M. F., Brindza, J. A., Michel, P. F., Bucklin, P., Belanger, P. J. and Prencipe, J. M., 1997, “Static and Dynamic Dent Resistance Performance of Automotive Steel Body Panels,”SAE Technical Paper No. 970158.

Swenson, W. E. and Trafkante, R. J., 1982, “The Influence of Aluminum Properties on the Design, Manufacturability and Economics of an Automotive Body Panel,”SAE Technical Paper No. 820385.

Thomas, D., Hodgins, R. B., Worswick, M. J., Oddy, A. S., Gong, K. and Finn, M., 1999, “FEM Technique for Static & Dynamic Dent Modelling of Aluminum,”Proceedings of Numisheet ’99 —Volume I, Gelin, J. C. and Picart, P., Eds., pp. 367–372.

Thorburn, H. J., 1994, “Comparitive Tests of Stiffness and Dent Resistance on Aluminum and Steel Fenders,”Proceedings IBEC ’94, International Body Engineering Conference, pp. 105–112.

Vadhavkar, A. V., Fecek, M. G., Shah, V. C. and Swenson, W. E., 1981, “Panel Optimization Program (POP),”SAE Technical Paper No. 810230.

Vreede, P. T., Tamis, P. J. and Roelofsen, M. E., 1995, “The Influence of Material Properties and Geometry on Dynamic Dent Resistance : Experiments and Simulations,”Proceedings IBEC ’95, International Body Engineering Conference, pp. 79–86.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jung, DW., Worswick, M.J. A parameter study for static and dynamic denting. KSME International Journal 18, 2009–2020 (2004). https://doi.org/10.1007/BF02990443

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02990443