Abstract

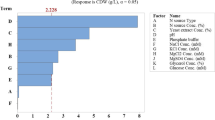

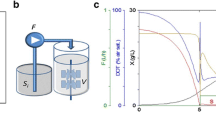

Preproinsulin is a well-known precursor of human insulin for the regulation of blood glucose levels. In this study, fed-batch fermentations of recombinantEscherichia coli JM109/pPT-MRpi were carried out for the overexpression of human preproinsulin. The expression of human preproinsulin was controlled by the temperature inducibleP2 promoter. The time-course profiles of fed-batch fermentation and SDS-PAGE analysis showed that human insulin expression was triggered by a culture temperature change from 30 to 37°C. Fermentation shift strategies, including the multi-step increase of temperature and the modulation of initiation time, were optimized to obtain high titers of cell mass and preproinsulin. The optimized fed-batch fermentation, consisting of a three-step shift of culture temperature from 30 to 37°C for 2 h, gave the best results of 43.1 g/L of dry cell weight and 33.3% preproinsulin content, which corresponded to 2.0- and 1.2-fold increases, respectively, as compared to those of fed-batch culture at a constant temperature of 37°C.

Similar content being viewed by others

References

Barfoed, H. C. (1987) Insulin production technology.Chem. Eng. Prog. 83: 49–54.

Norman, A. and G. Litwack (1987)Hormones. 1st ed., pp. 122–123. Academic Press, New York, NY, USA.

Ladisch, M. R. and K. L. Kohlmann (1992) Recombinant human insulin.Biotechnol. Prog. 8: 469–478.

Castellanos-Serra, L. R., E. Hardy, R. Ubieta, N. S. Vispo, C. Fernandez, V. Besada, V. Falcon, M. Gonzalez, A. Santos, G. Perez, A. Silva, and L. Herrera (1996) Expression and folding of an interleukin-2-proinsulin fusion protein and its conversion into insulin by a single step enzymatic removal of the C-peptide and the N-terminal fused sequence.FEBS Lett. 378: 171–176.

Evans, D. B., W. G. Tarpley, and S. K. Sharma (1991) Expression and characterization of chimeric rDNA proteins engineered for purification and enzymatic cleavage.Protein Expr. Purif. 2: 205–213.

Na, K. I., M. D. Kim, W. K. Min, J. A. Kim, W. J. Lee, D. O. Kim, K. M. Park, and J. H. Seo (2005) Expression and purification of ubiquitin-specific protease (UBP1) ofSaccharomyces cerevisiae in recombinantEscherichia coli.Biotechnol. Bioprocess Eng. 10:599–602.

Sharma, S. K., D. B. Evans, A. F. Vosters, T. J. McQuade, and W. G. Tarpley (1991) Metal affinity chromatography of recombinant HIV-1 reverse transcriptase containing a human renin cleavable metal binding domain.Biotechnol. Appl. Biochem. 14:69–81.

Park, Y. C., S. J. Kim, J. H. Choi, W. H. Lee, K. M. Park, M. Kawamukai, Y. W. Ryu, and J. H. Seo (2005) Batch and fed-batch production of coenzyme Q(10) in recombinantEscherichia coli containing the decaprenyl diphosphate synthase gene fromGluconobacter suboxydans.Appl. Microbiol. Biotechnol. 67: 192–196.

Wang, Y., P. Du, R. Gan, Z. Li, and Q. Ye (2005) Fedbatch cultivation ofEscherichia coli YK537 (pAET-8) for production ofphoA promoter-controlled human epidermal growth factor.Biotechnol. Bioprocess Eng. 10: 149–154.

Matsui, T., H. Yokota, S. Sato, S. Mukataka, and J. Takahashi (1989) Pressurized culture ofEscherichia coli for a high concentration.Agric. Biol. Chem. 53: 2115–2120.

Strandberg, L. and S. O. Enfors (1991) Batch and fed batch cultivations for the temperature induced production of a recombinant protein inEscherichia coli.Biotechnol. Lett. 13: 609–614.

Jensen, E. B. and S. Carlsen (1990) Production of recombinant human growth hormone inEscherichia coli: Expression of different precursors and physiological effects of glucose, acetate, and salts.Biotechnol. Bioeng. 36: 1–11.

Lan, J. C., T. C. Ling, G. Hamilton, and A. Lyddiatt (2006) A fermentation strategy for anti-MUC1 C595 diabody expression in recombinantEscherichia coli.Biotechnol. Bioprocess Eng. 11: 425–431.

Luli, G. W. and W. R. Strohl (1990) Comparison of growth, acetate production, and acetate inhibition ofEscherichia coli strains in batch and fed-batch fermentations.Appl. Environ. Microbiol. 56: 1004–1011.

Gleiser, I. E. and S. Bauer (1981) Growth ofEscherichia coli W to high cell concentration by oxygen level linked control of carbon source concentration.Biotechnol. Bioeng. 23: 1015–1021.

Rinas, U., H. A. Kracke-Helm, and K. Schugerl (1989) Glucose as a substrate in recombinant strain fermentation technology: by-product formation, degradation and intracellular accumulation of recombinant protein.Appl. Microbiol. Biotechnol. 31: 163–167.

Yee, L. and H. W. Blanch (1993) Recombinant trypsin production in high cell density fed-batch cultures inEscherichia coli.Biotechnol. Bioeng. 41: 781–790.

Birch, R. M. and G. M. Walker (2000) Influence of magnesium ions on heat shock and ethanol stress responses ofSaccharomyces cerevisiae.Enzyme Microb. Technol. 26: 678–687.

Wouters, J. A., H. H. Kamphuis, J. Hugenholtz, O. P. Kuipers, W. M. de Vos, and T. Abee (2000) Changes in glycolytic activity ofLactococcus lactis induced by low temperature.Appl. Environ. Microbiol. 66: 3686–3691.

Buttrick, P. (2006) The regulation of heat shock protein expression: How, when and where.J. Mol. Cell. Cardiol. 41: 785–786.

Lamotte, D., M. Ouzzine, S. Fournel-Gigleux, J. Magdalou, and J. Boudrant (1996) A temperature profile in batch culture to increase the production of the recombinant UDP-glucuronosyltransferase 2B4 inEscherichia coli.Process Biochem. 31: 235–241.

Lukacsovich, T., G. Baliko, A. Orosz, E. Balla, and P. Venetianer (1990) New approaches to increase the expression and stability of cloned foreign genes inEscherichia coli.J. Biotechnol. 13: 243–250.

Rasmussen, L. J., A. Lobner-Olesen, and M. G. Marinus (1995) Growth-rate-dependent transcription initiation from the dam P2 promoter.Gene 157: 213–215.

Murray, H. D., J. Alex Appleman, and R. L. Gourse (2003) Regulation of theEscherichia coli rrnB P2 promoter.J. Bacteriol. 185: 28–34.

Kim, S. G., D. H. Kweon, D. H. Lee, Y. C. Park, and J. H. Seo (2005) Coexpression of folding accessory proteins for production of active cyclodextrin glycosyltransferase ofBacillus macerans in recombinantEscherichia coli.Protein Expr. Purif. 41: 426–432.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Son, YJ., Park, KH., Lee, SY. et al. Effects of temperature shift strategies on human preproinsulin production in the fed-batch fermentation of recombinantEscherichia coli . Biotechnol. Bioprocess Eng. 12, 556–561 (2007). https://doi.org/10.1007/BF02931354

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02931354