Abstract

Lactic acid is a green chemical that can be used as a raw material for biodegradable polymer. To produce lactic acid through microbial fermentation, we previously screened a novel lactic acid bacterium. In this work, we optimized lactic acid fermentation using a newly isolated and homofermentative lactic acid bacterium. The optimum medium components were found to be glucose, yeast extract, (NH4)2HPO4, and MnSO4. The optimum pH and temperature for a batch culture ofLactobacillus sp. RKY2 was found to be 6.0 and 36°C, respectively. Under the optimized culture conditions, the maximum lactic acid concentration (153.9 g/L) was obtained from 200 g/L of glucose and 15 g/L of yeast extract, and maximum lactic acid productivity (6.21 gL−1h−1) was obtained from 100 g/L of glucose and 20 g/L of yeast extract. In all cases, the lactic acid yields were found to be above 0.91 g/g. This article provides the optimized conditions for a batch culture ofLactobacillus sp. RKY2, which resulted in highest productivity of lactic acid.

Similar content being viewed by others

References

Davison, B. E., R. L. Llanos, M. R. Cancilla, N. C. Redman, and A. J. Hillier (1995) Current research on the genetics of lactic acid production in lactic acid bacteria.Int. Dairy J. 5: 763–784.

Datta, R., S. P. Tsai, P. Bonsignore, S. H. Moon, and J. R. Frank (1995) Technological and economic potential of poly(lactic acid) and lactic acid derivatives.FEMS Microbiol. Rev. 16: 221–231.

Richter, K. and C. Berthold (1998) Biotechnological conversion of sugar and starch crops into lactic acid.J. Agric. Eng. Res. 71: 181–191.

Yang, Y. J., S. H. Hwang, S. M. Lee, Y. J. Kim, and Y. M. Koo (2002) Continuous cultivation ofLactobacillus rhamnosus with cell recycleing using an acoustic cell settler.Biotechnol. Bioprocess Eng. 7: 357–361.

Varadarajan, S. and D. J. Miller (1999) Catalytic upgrading of fermentation-derived organic acids.Biotechnol. Prog. 15: 845–854.

Amass, W., A. Amass, and B. Tighe (1998) A review of biodegradable polymers: Uses, current developments in the synthesis and characterization of biodegradable polymers, blends of biodegradable polymers and recent advances in biodegradation studies.Polym. Int. 47: 89–114.

Vink, E. T. H., K. R. Rábago, D. A. Glassner, and P.R. Gruber (2003) Applications of life cycle assessment to NatureWorksTM polylactides (PLA) production.Polym. Degrad. Stabil. 80: 403–419.

Litchfield, J. H. (1996) Microbiological production of lactic acid.Adv. appl. Microbiol. 42: 45–95.

Bai, D. M., X. M. Zhao, X. G. Li, and S. M. Xu (2004) Strain improvement ofRhizopus oryzae for over-production of L(+)-lactic acid and metabolic flux analysis of mutants.Biochem. Eng. J. 18: 41–48.

Miura, S., L. Dwiarti, T. Arimura, M. Hoshino, L. Tiejun, and M. Okabe (2004) Enhanced production ofl-lactic acid by ammonia-tolerant mutant strainRhizopus sp. MK-96-1196.J. Biosci. Bioeng. 97: 19–23.

Yun, J. S., Y. J. Wee, and H. W. Ryu (2003) Production of optically purel(+)-lactic acid from various carbohydrates by batch fermentation ofEnterococcus faecalis RKY1.Enzyme Microb. Technol. 33: 416–423.

Hofvendahl, K. and B. Hahn-Hägerdal (2000) Factors affecting the fermentative lactic acid production from renewable resources.Enzyme Microb. Technol. 26: 87–107.

Stiles, M. E. and W. H. Holzapfel (1997) Lactic acid bacteria of foods and their current taxonomy.Int. J Food Microbiol. 36: 1–29.

Berry, A. R., C. M. M. Franco W. Zhang and A. P. J. Middelberg (1999) Growth and lactic acid production in batch culture ofLactobacillus rhamnosus in a defined medium.Biotechnol. Lett. 21: 163–167.

Butos, G., A. B. Moldes, J. L. Alonso, and M. Vázquez (2004) Optimization ofd-lactic acid production byLactobacillus coryniformis using response surface methodology.Food Microbiol. 21: 143–148.

Hofvendahl, K., E. W. J. van Niel, and B. Hahn-Hägerdal (1999) Effect of temperature and pH on growth and product formation ofLactobacillus lactis ssp.lactis ATCC 19435 growing on maltose.Appl. Microbiol. Biotechnol. 51: 669–672.

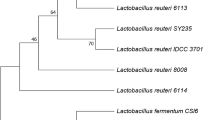

Wee, Y. J., J. S. Yun, D. H. Park, and H. W. Ryu (2004) Isolation and characterization of a novel lactic acid bacterium for the production of lactic acid.Biotechnol. Bioprocess Eng. 9: 303–308.

Lee, J. H., M. H. Choi, J. Y. Park, H. K. Kang, H. W. Ryu, C. S. Sunwo, Y. J. Wee, K. D. Park, D. W. Kim, and D. Kim (2004) Cloning and characterization of the lactate dehydrogenase genes fromLactobacillus sp. RKY2.Biotechnol. Bioprocess Eng. 9: 318–322.

deMan, J. C., M. Rogosa, and M. E. Sharpe (1960) A medium for the cultivation of lactobacilli.J. Appl. Bacteriol. 23: 130–135.

Stainer, R. Y., J. L. Ingraham, M. L. Wheelis, and P. R. Painter (1986)The Microbial World. 5th ed., pp. 495–504. Prentice Hall, NY, USA.

Angelis, M. D. and M. Gobbetti (1999)Lactobacillus sanfranciscensis CB1: Manganese, oxygen, superoxide dismutase and metabolism.Appl. Microbiol. Biotechnol. 51: 358–363.

Bruno-Bárcena, J. M., A. L. Ragout, P. R. Córdoba, and F. Siñeriz (1999) Continuous production ofl(+)-lactic acid byLactobacillus casei in two-stage systems.Appl. Microbiol. Biotechnol. 51: 316–324.

Åkerberg, C., K.Hofvendahl, G. Zacchi, and B. Hahn-Hägerdal (1998) Modeling the influence of pH, temperature, glucose and lactic acid concentrations on the kinetics of lactic acid production byLactococcus lactis ssp.lactis ATCC 19435 in whole-wheat flour.Appl. Microbiol. Biotechnol. 49: 682–690.

Ohara, H., K. Hiyama, and T. Yoshida (1992) Noncompetitive product inhibition in lactic acid fermentation from glucose.Appl. Microbiol. Biotechnol. 36: 773–776.

Hujanen, M., S. Linko, Y. Y. Linko, and M. Leisola (2001) Optimization of media and cultivation conditions forl(+)(S)-lactic acid production byLactobacillus casei NRRL B-441.Appl. Microbiol. Biotechnol. 56: 126–130.

Hujanen, M. and Y. Y. Linko (1999) Effect of temperature and various nitrogen sources onl(+)-lactic acid production byLactobacillus casei.Appl. Microbiol Biotechnol. 45: 307–313.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wee, YJ., Kim, JN., Yun, JS. et al. Optimum conditions for the biological production of lactic acid by a newly isolated lactic acid bacterium,Lactobacillus sp. RKY2. Biotechnol. Bioprocess Eng. 10, 23–28 (2005). https://doi.org/10.1007/BF02931178

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02931178