Abstract

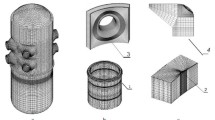

This study is concerned with structural integrity evaluations for the interference-fit flywheels in reactor coolant pumps (RCPs) of nuclear power plants. Stresses in the flywheel due to the shrinkage loads and centrifugal loads at the RCP normal operation speed, design overspeed and joint-release speed are obtained using the finite element method (FEM), where release of the deformation-controlled stresses as a result of structural interactions during rotation is considered. Fracture mechanics evaluations for a series of cracks assumed to exist in the flywheel are conducted, considering ductile (fatigue) and non-ductile fracture, and stress intensity factors are obtained for the cracks using the finite element alternating method (FEAM). From analysis results, it is found that fatigue crack growth rates calculated are negligible for smaller cracks. Meanwhile, the material resistance to non-ductile fracture in terms of the critical stress intensity factor(K IC) and the nil-ductility transition reference temperature RTinNDT are governing factors for larger cracks.

Similar content being viewed by others

Abbreviations

- a :

-

Inner radius of flywheel disc [mm]

- b :

-

Outer radius of flywheel disc [mm]

- C o :

-

Scaling constant

- c/a :

-

Ratio of half length (c)-to-depth (a) of elliptical crack

- da/dN :

-

Fatigue crack growth per load cycle

- E :

-

Elastic modulus of material [KN/mm2]

- K :

-

Stress intensity factor of crack

- K l :

-

Mode I stress intensity factor of crack

- n :

-

Slope of log (da/dN) vs. log (ΔAKl) curve

- P :

-

Primary stress intensity [N/mm2]

- P b :

-

Primary bending stress intensity [N/mm2]

- P m :

-

Primary membrane stress intensity [N/mm2]

- Q :

-

Secondary stress intensity [N/mm2]

- R :

-

Cyclic load ratio ofKmm to kmax

- δ :

-

Radial distance in flywheel disc [mm]

- δ M :

-

Mean radius of flywheel disc, (a+b)/2 [mm]

- S :

-

Scaling parameter

- S m :

-

Design stress intensity value [N/mm2]

- z :

-

Distance in the meridional direction along the thickness of flywheel [mm]

References

ASME Boiler and Pressure Vessel Code, 2001, Section II - Material Specification, American Society of Mechanical Engineers.

ASME Boiler and Pressure Vessel Code, 2001, Section III - Nuclear Power Plant Components, American Society of Mechanical Engineers.

ASME Boiler and Pressure Vessel Code, 2001, Section XI - Rules for Inspection and Testing of Components of Light-Water Cooled Plants, American Society of Mechanical Engineers.

Bae, D. H., Kwon, S. D, Song, S. J. and Lee, Y. Z., 2002, “Nondestructive Evaluation of the Characteristics of Degraded Materials Using Backward Radiated Ultrasound,”KSME International Journal, Vol. 16, pp. 1084–1092.

Hibbit, Karlsson & Sorensen, Inc., 1998, ABAQUS/Standard User’s Manual, Version 5.8, Providence, RI.

Kamaya, M. and Nishioka, T., 2004, “Evaluation of Stress Intensity Factors by Finite Element Alternating Method,” PVP-Vol. 481, RPV Integrity and Fracture Mechanics, ASME, pp. 113-120.

Nikishkov, G. P., Park, J. H. and Atluri, S. N., 2001, “SGBEM-FEM Alternating Method for Analyzing 3D Non-planar Cracks and Their Growth in Structural Components,”Computer Modeling in Engineering and Science, Vol. 2, pp. 401–422.

Park, J. H., Park, S. Y., Kim, M. W., Park, J. S. and Jin, T. E., 2004, “Development of a Code for 2D Elasto-Plastic Fracture Mechanics Analyses Using the Finite Element Alternating Method,”Key Engineering Materials, Vols. 270-273, pp. 1159–1164.

Riccardella, P. C. and Bamford, W. H., 1974, “Reactor Coolant Pump Flywheel Overspeed Evaluation,”Journal of Pressure Vessel Technology.

Song, J. L, Kim, S. and Shim, Y. L., 2002, “Residual Stress and Fracture Analysis of Thick Plate for Partial Penetration Multi-Pass Weldment,”KSME International Journal, Vol. 16, pp. 1033–1039.

USNRC Regulatory Guide 1.14, 1975, “Reactor Coolant Pump Flywheel Integrity,” Rev.l.

USNRC Information Notice No. 84–92, 1984, “Cracking of Flywheels on Cummins Fire Pump Diesel Engines”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, Js., Song, Hc., Yoon, Ks. et al. Structural integrity evaluation for interference-fit flywheels in reactor coolant pumps of nuclear power plants. J Mech Sci Technol 19, 1988–1997 (2005). https://doi.org/10.1007/BF02916491

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02916491