Abstract

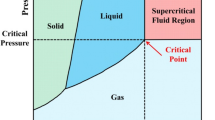

In the processing of microcellular foamed polymer products, one of the most important factors is the dependence of rheology on the mixture ratio of the polymer and the gas used as the blowing agent. The formation of a cell by employing the thermodynamic instability of the gas in a one-phase condition is the principle behind microcellular foaming. The viscosity change of the polymer and gas mixture is important in designing dies and molds and affects the quality of the microcellular foaming product. In this experiment, the extruder was modified to mix polymer with gas under a one-phase melted condition. The mixed polymer with gas was run through various capillary die shapes to measure the change in polymer viscosity against the gas supply rate. This paper describes the effect of talc and the blowing agent on the viscosity in continuous microcellular processes, revealing major factors in determining the viscosity of a polymer and gas mixture.

Similar content being viewed by others

References

C. B. Park and N. P. Suh,SPE ANTEC Tech Papers,39, 1818 (1993).

C. B. Park, D. F. Baldwin, and N. P. Suh,Polym. Eng. Sci.,35, 5 (1995).

J. Martini, F. A. Waldman, and N. P. Suh,SPE ANTEC Tech Papers,28, 674 (1982).

S. W. Cha and N. P. Suh,SPE ANTEC Tech Papers,37, 11527 (1992).

K. A. Seeler and V. Kumar,Cellular Polymers,38, 93 (1992).

D. F. Baldwin, D. E. Tate, C. B. Park, S. W. Cha, and N. P. Suh,J. Japan Soc. Polym. Proc.,6, 187 & 245 (1994).

D. Wee, D. G. Seong, and J. R. Youn,Fibers and Polymers,5, 160 (2004).

X. Wu, C. Lu, G. Wu, R. Zhang, and L. Ling,Fibers and Polymers,6, 103 (2005).

L. M. Matuana, C. B. Park, and J. J. Balatinecz,Cellular Polymers,17, 1 (1998).

V. Kumar, R. P. Juntunen, and C. Barlow,Cellular Polymers,19, 1 (2000).

R. P. Juntunen, V. Kumar, J. E. Weller, and W. R. Bezubic,J. Vinyl Additive Tech.,6, 2 (2000).

C. C. Barlow, V. Kumar, B. Flinn, R. K. Bordia, and J. Weller,J. Eng. Mater. Technol.,123, 229 (2001).

D. I. Collias and D. G. Baird,SPE ANTEC Tech Papers,38, 1532 (1992).

M. R. Holl, V. Kumar, J. L. Garbini, and W. R. Murray,J. Mater. Sci.,34, 637 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moon, Y., Cha, S.W. Study on viscosity changes with talc in microcellular foaming process. Fibers Polym 8, 393–398 (2007). https://doi.org/10.1007/BF02875828

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02875828