Abstract

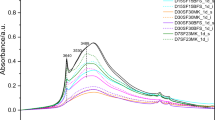

The pozzolanic activity of coal gangue burned at different burning temperatures was investigated. The burned coal gangue was mixed with portland cement in different proportions (20%–60%). The pozzolanic activity of coal gangue burned and the hydration, products were examined, the compressive strengths of the pastes of the mixtures were tested, and the mechanism of the reaction was discussed. The experimental results show that the coal gangue burned at 750 °C has the optimum pozzolanic activity, and the burned coal gangue with SiO2 and Al2O3 is in an active form. When the coal gangue burned at 750 °C is mixed into portland cement, the content of calcium hydroxide in paste is significantly reduced, while the contents of hydrated calcium silicate and hydrated calcium aluminate are increased accordingly, hence resulting in the improvement of the microstructure of mortar. The compressive strength of cement paste decreases with increasing the content of burned coal gangue. The decease in strength is small in the range of 20%–30% coal gangue substitution and significant in 30%–60% substitution.

Similar content being viewed by others

References

Cai Jingqang. A New Approach to High-effective Use of Coal Gangue[J].J. Rare and Hard Metal., 2000, (6): 37

Clement Greco and Guido Picciotti. Pozzolan Production[J].J. World Cement, 2001, 32(10): 39–43

B B Sabir, S Wild, J Bai. Metakaolin and Calcined Clays as Pozzolans for Concrete: A Review[J].J. Cement and Concrete Composites, 2001, 23(6): 441–454

C S Poon, S C Kou, L Lampore. Size Distribution of High Performance Metakaolin Concrete[J].J. Wuhan University of Technology—Mater. Sci. Ed., 2002, 17: 42–46

Ding Zhu, Zhang Decheng, Wang Xiangdong. Research and Application of Pozzolanic Activity of Metakaolin[J].J. Bulletin of the Chinese Ceramic Society, 1997, (4): 57–62

Gao Qiongying, Zhang Zhiqiang. Study on the Structure Change in the Calcination Process of Kaolinite and Its Pozzolanic Activity [J].J. Journal of the Chinese Ceramic Society, 1998, 17(6): 541–548

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by Social Development Plan in Science and Technology of Jiangsu Province (No. BS2006033)

Rights and permissions

About this article

Cite this article

Changsen, Z. Pozzolanic activity of burned coal gangue and its effects on structure of cement mortar. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 21, 150–153 (2006). https://doi.org/10.1007/BF02841227

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02841227