Abstract

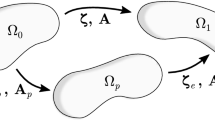

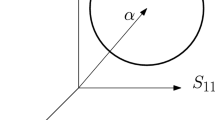

This article discusses the application of the visioplasticity method to the evaluation of large plastic strains such as those occurring in metalforming. Although this method can be used for any mode of deformation, its application to plane-strain deformation is treated here. The distortion of a quadrilateral element of a grid is tracked to compute strains during deformation. In each case any two lines of the quadrilateral can be used (length before and after deformation and direction cosines before deformation) to determine strains in the element. The method has been verified by application to basic cases of deformation such as uniaxial compression, tension, pure shear, and rotation of elements. The effect of choice of lines upon the results of strain calculation is also discussed.

Similar content being viewed by others

References

E.G. Thomsen, C.T. Yang, and S. Kobayashi,Plastic Deformation in Metal Processing, Macmillan, New York, 1965.

A.H. Shabaik and E.G. Thomsen, “A Theoretical Method for the Analysis of Metal-Working Problems,”J. Eng. Ind., 90, p. 343, May 1968.

A.H. Shabaik and E.G. Thomsen, “Computer Application to the Visioplasticity Method,”J. Eng. Ind., 89, p. 339, May 1967.

L.E. Farmer and P.L.B. Oxley, “A Computer-Aided Method for Calculating the Distributions of Strain Rate and Strain from an Experimental Flow Field,”J. Strain Analysis, 11, p. 26, 1976.

T.H.C. Childs, “Metal Flow in the Hot Extrusion of Mild Steel,”Metals Technol., 1, p. 305 (1974).

F.P. Chiang and P. Hareesh, “An Experimental Numerical Study of Cylindrical Extrusion Using Moiré Technique,” in13th NAMRC Proceedings (NAMRIO, SME, Dearborn, Michigan, 1985), p. 184.

R. Sowerby, E. Chu, and J.L. Duncan, “Determination of Large Strains in Metal Forming,”J. Strain Analysis, 17, p. 95, 1982.

R. Sowerby and P.C. Chakravarti, “The Determination of the Equivalent Strain in Finite, Homogeneous Deformation Process,”J. Strain Analysis, 18, p. 121, 1983.

H. Ford and J.M. Alexander,Advanced Mechanics of Materials, Halsted Press, New York, 1977.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jain, V.K., Matson, L.E., Gegel, H.L. et al. Physical modeling of metalworking processes—I: Determination of large plastic strains. J. Materials Shaping Technology 5, 243–248 (1988). https://doi.org/10.1007/BF02836004

Issue Date:

DOI: https://doi.org/10.1007/BF02836004