Abstract

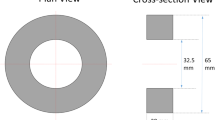

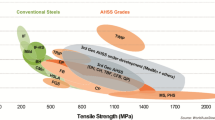

Galvanized steels have been increasingly used to improve the corrosion resistance of automobiles, particularly of corrosion critical components. In addition to the studies of the effect of coating on weldability and paintability, a further understanding of the effect of galvanized coating on the formabilities of steel is needed. Two forming tests, i.e., limiting dome height and hole expansion, were used to determine the plane strain and edge formabilities of four widely-used, hot-dipped galvanized high strength steels both in the as-coated and the as-stripped conditions. These two modes of fracture are believed to be the most frequently encountered problems in stamping operations. The results indicate that the hot-dipped galvanized coating increases the plane strain formability while it decreases the edge formability of high strength steels. Thus, galvanized steel and uncoated steel are interchangeable in plane strain-controlled applications. However, when regular uncoated steel is replaced with galvanized steel in edge/flange stretching-controlled applications, care must be exercised in determining blank size and tooling design.

Similar content being viewed by others

References

J. Mackowiak and N. R. Short:International Metal Review, 1979, vol. 1, p. 1.

The Study and Prevention of Corrosion SP-538, SAE, Warrendale, PA, Feb. 1983.

Proceedings of the 2nd Automotive Corrosion Prevention Conference, SAE, Warrendale, PA, Dec. 1983.

R.Stevenson:Proc. 1982 American Institute of Physics, 1982, p. 297.

R. Stevenson: General Motors Research publication GMR-4283, Feb. 1983.

D. J. Meulemanet al.: SAE paper #840370, Warrendale, PA, 1984.

S.S. Hecker:Formability: Analysis, Modeling and Experimentation, S.S. Heckeret al., eds., AIME, 1978.

R. A. Ayreset al.:J. Applied Metalworking, 1979, vol. 1, p. 41.

A. K. Ghosh:Metals Engineering Quarterly, 1975, vol. 15, p. 53.

A. S. Kasperet al.:Advances in Deformation Processing—21st Sagamore Army Materials Research Conference, Aug. 13–16, 1974.

R. R. Pradhan:Proc. of the 21st Mechanical Working & Steel Processing Conference at Cleveland, OH, Oct. 24–25, AIME, 1979, p. 1.

T. E. Fineet al.: Proc. of the 19th Mechanical Working and Steel Processing Conference at Pittsburgh, PA, Jan., AIME, 1977, p. 313.

S.P. Keeler: National Steel Corporation, private communication.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cheng, F.L., Aichbhaumik, D. The effect of hot-dipped galvanized coating on the edge and plane strain formabilities of high strength steels. J. Applied Metalworking 4, 176–182 (1986). https://doi.org/10.1007/BF02834381

Issue Date:

DOI: https://doi.org/10.1007/BF02834381