Abstract

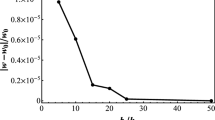

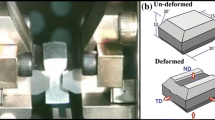

A method to determine surface strains in industrially stamped sheet panels has been studied. The method incorporates a quadrilateral grid imposed to the blank and automatic image analysis. The quadrilateral grid makes it possible to analyze complex strain histories with rotations of the deformation system. The grid size can easily be increased from a minimum value upward during the analysis of a panel, for example, from one area to the next. In areas of the panel where cracking occurs, a small size grid is required because of the sharp strain gradients close to the crack. In relatively flat areas of the panel with low levels of strain attention is usually focused on strain variations over larger distances than in failure regions, and larger grids are used. Such long range strain variations are of interest in analyzing buckling, springback, or shape fixation. An inner auto body component was stamped in a high strength rephosphorized sheet steel and analyzed in some detail. Complex strain histories were identified with rotations of the deformation system. The distribution of strains in different areas of the stamping was determined. The analysis gives both the magnitude of the strains and the direction of the largest strain. Such information can be used by a die engineer in tooling development and in selecting blank holder pressure. Cracking occurred at one location of the stamping. The corresponding strain path was complex. The failure could be predicted with the present strain analysis and the forming limit diagram.

Similar content being viewed by others

References

R. Sowerby, J. L. Duncan, and M. P. Sklad: “Large engineering strain, theory and the measurement of strain in pressings,” Internal report at the Department of Mechanical Engineering, McMaster University, Hamilton, ON L8S 4L7, Canada.

R. Sowerby, E. Chu, and J. L. Duncan: “Determination of large strains in metalforming,”J. Strain Analysis, 1982, vol. 17 (2), pp. 95–101.

T. C. Hsu: “The characteristics of coaxial and noncoaxial strain paths,”J. Strain Analysis, 1966, vol. 1 (3), pp. 216–22.

R. Sowerby and P. C. Chakravarti: “The determination of the equivalent strain in finite, homogeneous deformation processes,”J. Strain Analysis, 1983, vol. 18 (2), pp. 119–23.

B. Ekmark: “On large strain theories in sheet metal forming, general theories and numerical considerations with particular emphasis on strain analysis, nonconservative loading and plastic anisotropy,” Doctorial Thesis, 1983:24D, University of Luleå, Sweden.

E. Schedin, M. Hedman, and A. Melander: “Influence of sheet thickness on the forming limit diagrams and the strain distributions of rephosphorized steels,” Swedish Institute for Metals Research, Report IM-1864.

A. Melander and E. Schedin: “Influence of non-linear strain paths on the forming limit diagrams of a deep drawing quality steel and a dual phase steel,”Proc. Int. Conf. Technology and Applications of High Strength Low Alloy Steels, Philadelphia, PA, October 1983.

W. Muschenborn and H-M. Sonne: “Influence of the strain path on the forming limits of sheet metal,”Arch. Eisenhüttenwesen, 1975, vol. 46, pp. 597–602.

C. Y. Choi and T. C. Hsu: “Mohr circles for large and small strains in two-dimensional deformations,”J. Strain Analysis, 1971, vol. 6 (1), pp. 62–69.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Schedin, E., Melander, A. The evaluation of large strains from industrial sheet metal stampings with a square grid. J. Applied Metalworking 4, 143–156 (1986). https://doi.org/10.1007/BF02834378

Issue Date:

DOI: https://doi.org/10.1007/BF02834378