Abstract

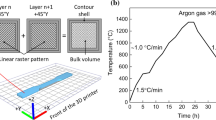

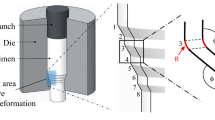

The feasibility of a new process that integrates all thermal and mechanical operations involved in the production of wrought metal strips was examined. The process involves continuous extrusion on a screw type extruder. A Pb-2.0% Sb alloy was used as a model material. Continuous strips of metal could be produced when back leakage of the melt was limited. For this, the clearance between screw and extruder barrel had to be kept small and the viscosity of the partially solidified alloy had to be kept high by limiting the rotational speed and by maintaining an experimentally determined temperature profile along the extruder barrel. Intense shearing of the material resulted in rapid homogenization and in dynamic recrystallization of the metallic matrix.

Similar content being viewed by others

References

A. S. El-Gizawy, and J. A. Schey, “Product Microstructure and Properties Induced by Hot Working a Pb-1.85% Sb Alloy,”Metallurgical Transactions, 16A 1985, pp. 1273–1283.

A. S. El-Gizawy, and J. A. Schey, “Application of Controlled Rolling to a Low-Antimony Lead Alloy,”Canadian Metallurgical Quarterly, 24, 1985, pp. 91–99.

M. Kiuchi, S. Sugiyama, and K. Arai, “Study of Metal Forming in the Mushy State 1st Report: Flow Stress and Deformation Behaviour of Alloy in Mushy State,” Proceedings of the 20th Int. MTDR Conference, 1980, pp. 71–78.

M. Kiuchi, S. Sugiyama, and K. Arai, “Study of Metal Forming in Mushy State 2nd Report: Extrusion of Tube, Bar, and Wire of Alloys in Mushy State,” Proceedings of the 20th Int. MTDR Conference, 1980, pp. 79–86.

M. Kiuchi, “Application of Mushy-State Working Processes to Production of Metal-Ceramics Composites,”Annals of the CIRP, 36, 1987, pp. 173–176.

S. D. E. Ramati, G. J. Abbuschian, D. G. Backman, and R. Mehrabian, “Forging of Liquid and Partially Solid Sn-15% Pb and Aluminium Alloys,”Metallurgical Transactions, 9B, 1978, pp. 279–286.

M. C. Flemings,Solidification Processing, McGraw-Hill, New York, 1974.

G. Williams, and K. M. Fisher, “Squeeze Forming of Aluminium-Alloy Components,”Metals Technology, 8, 1981, pp. 263–271.

A. S. El-Gizawy, “The Role of Thermomechanical Processing in Controlling Microstructure and Properties of Low-Antimony Lead Alloys,” Ph.D. Thesis, University of Waterloo, Waterloo, Ontario, 1983.

H. P. Stuwe, “Einige Abschatzungen zum Strangpressen,Metall, 22, 1968, pp. 1197–1200.

S. Kalpakjian,Manufacturing Processes for Engineering Materials, Addison-Wesley, Reading, Massachusetts, 1991.

J. A. Schey,Introduction to Manufacturing Processes, McGraw Hill, New York, 1987.

D. B. Spencer, R. Mehrabian, and M. C. Flemings, “Rheological Behavior of Sn-15% Pb in the Crystallization Range,”Metallurgical Transactions, 3, 1972, pp. 1925–1932.

M. M. Kamal, “A High Pressure Clearance Seal,” ASME,J. Lubrication Technology, 1968, pp. 412–416.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

El-Gizawy, A.S. Novel processing method for metallic materials. J. Materials Shaping Technology 9, 183–192 (1991). https://doi.org/10.1007/BF02833643

Issue Date:

DOI: https://doi.org/10.1007/BF02833643