Abstract

The liquefaction of coal to produce clean-burning synthetic fuels has been demonstrated at the pilot plant level. However, some significant materials problems should be solved to enable economic and reliable scale-up to commercial levels of production. Failures due to inadequate materials performance have been reported in many plant areas; in particular, stress corrosion cracking has been found in austenitic stainless steels in the reaction and separation areas, and severe corrosion has been observed in fractionation components. In order to screen candidate materials of construction, racks of U-bend specimens in welded and as-wrought conditions and unstressed surveillance coupons were exposed in pilot plant vessels and examined. Failed components were analyzed on-site and by subsequent laboratory work. Laboratory tests were also performed. These studies have identified alloys that are suitable for critical plant locations.

Similar content being viewed by others

References

Monthly, quarterly, and annual technical progress reports are available: H. E. Lewiset al, Solvent Refined Coal (SRC) Process: Operation of Solvent Refined Coal Pilot Plant at Wilsonville, Alabama, FE/2270-0-55).

Monthly, quarterly, and annual technical progress reports are available:Solvent Refined Coal (SRC) Process, FE/496-(l-175).

U. Blom: “Polythionic Acid Cracking in Stainless Steel and Alloys,”Chemical Economy and Engineering Review, vol. 4, no. 4, 1972, p. 47.

A. J. Brophy: “Stress Corrosion Cracking in Austenitic Stainless Steels in Refinery Environments,”Materials Performance, vol. 13, no. 9, 1974, p. 9.

C. H. Samans: “Stress Corrosion Cracking Susceptibility of Stainless Steels and Nickel-Base Alloys in Polythionic Acids and Acid Copper Sulfate Solution,”Corrosion, vol. 20, 1964, p. 256t.

E. Lendvai-Lintner: “Stainless Steel Weld Overlay Resistance to Polythionic Acid Attack,”Materials Performance, vol. 18, no. 3, 1979, p. 9.

A. V. Allesandria and N. Jaggard: “Refiners Report New Cases of Stainless Steel Failure,”Petroleum Refiner, vol. 39, 1960, p. 151.

J. J. Heller and G. R. Prescott: “Cracking of Stainless Steels in Wet Sulfidic Environments in Refinery Units,”Materials Protection, vol. 5, no. 9, 1965, p. 14.

S. D. Snyder and B. C. Leslie:In-Service Inspection of the Dissolver Tank in the Solvent-Refined Coal Pilot Plant at Wilsonville, Alabama, ORNL/TM-6277, Oak Ridge National Laboratory, Oak Ridge, Tenn., April 1978.

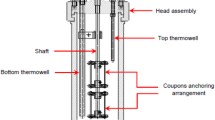

J. H. DeVan, B. C. Leslie, and R. T. King:Analysis of Blind Flange and Thermowell Assembly from Wilsonville, Alabama, Solvent Refined Coal Plant Dissolver Tank, ORNL/TM-6379, Oak Ridge National Laboratory, Oak Ridge, Tenn., July 1978.

D. R. Canfield, S. Ibarra, and J. D. McCoy, “SRC Corrosion Can Be Solved!,”Hydrocarbon Processing, vol. 55, July 1979, p. 203.

V. B. Bayloret al: Stress Corrosion Studies in Solvent Refined Coal (SRC) Liquefaction Pilot Plants, ORNL/TM-7513, Oak Ridge National Laboratory, Oak Ridge, Tenn., to be published.

J. Sorell: Exxon Research and Engineering Company, Florham Park, N.J., private communications, 1978–80.

S. J. Ibarra: Gulf Science and Technology Company, Pittsburgh, Pa., private communications, 1978–80.

K. L. Baumert: Air Products and Chemicals, Inc., Allentown, Pa., private communication, 1979.

V. B. Bayloret al:Analysis of T-105 Fractionation Column Failure at the Wilsonville, Alabama, Solvent Refined Coal (SRC) Pilot Plant, ORNL/TM-7327, Oak Ridge National Laboratory, Oak Ridge, Tenn., July 1980.

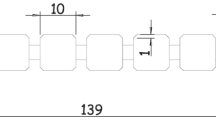

V. B. Bayloret al: Metallographic Examination of Surveillance Coupons from the Wilsonville, Alabama, Solvent Refined Coal Pilot Plant, 1977–1978, ORNL/TM-7365, Oak Ridge National Laboratory, Oak Ridge, Tenn., July 1980.

A. L. Blount:API Proceedings, Section 3, vol. 11, no. 75, 1930, p. 102.

W. A. Derungs: “Naphthenic Acid Corrosion—An Old Enemy of the Petroleum Industry,”Corrosion, vol. 12, 1956, p. 617t.

C. H. Samanset al: “Selection of Steel for High-Temperature Service in Petroleum Refinery Applications,”Metals Handbook, 8th ed., vol. 1, American Society for Metals, Metals Park, Ohio, 1961, p. 585.

J. J. Heller: “Corrosion of Refinery Equipment by Naphthenic Acid,”Materials Performance, vol. 2, no. 9, 1963, p. 9.

A. J. Breen: “Primary Petroleum Distillation Plant—Selection of Materials,”British Corrosion Journal, vol. 9, no. 4, 1974, p. 197.

J. Gutzeit: “Studies Shed Light on Naphthenic Acid Corrosion,”Oil and Gas Journal, vol. 74, 1976, p. 156.

J. Gutzeit: “Naphthenic Acid Corrosion in Oil Refineries,”Materials Performance, vol. 16, no. 10, 1977, p. 24.

Committee of Stainless Steel Producers:The Role of Stainless Steels in Petroleum Refining, Washington, D.C., April 1977.

R. L. Piehl: “Correlation of Corrosion in a Crude Distillation Unit with Chemistry of the Crudes,”Corrosion, vol. 16, no. 6, 1960, p. 305t.

K. Reiser: “The Control of Corrosion in Refinery Distillation Units,”Journal of the Institute of Petroleum, vol. 53, no. 527, 1967, p. 352.

R. S. Little, W. H. Baum, and J. P. Anerousis: “How to Control Crude Unit Overhead Corrosion,”Hydrocarbon Processing, vol. 53, May 1977, p. 205.

R. B. Wells and H. S. Carson: “Chemical Control of Crude Unit Corrosion and Fouling Problems,” unpublished paper 134, presented at NACE Corrosion/78, March 1978.

E. Mohsen: “Overhead Corrosion Control in Crude Distillation Unit,” unpublished paper 132, presented at NACE Corrosion/78, March 1978.

R. J. Hafsten and K. R. Walston: “Neutralizers and Inhibitors Today,”Petroleum Refiner, vol. 34, no. 5, 1955, p. 163.

E. C. French and W. F. Fahey: “HCl Not Sole Culprit in Crude Overhead Corrosion,”Oil and Gas Journal, vol. 77, 1979, p. 67.

C. P. Larabee and W. L. Mathay: “Controlling Corrosion in Coal Chemical Plants,”Corrosion, vol. 14, 1958, p. 183t.

R. C. Cronau: “Reducing Corrosion in Coal Tar Distillation Equipment,”Materials Protection, vol. 4, no. 12, 1965, p. 52.

R. C. Cronau and B. E. Wilde: “Procedures for Minimizing Corrosion in Coal-Chemical Facilities,” unpublished paper 90, presented at NACE Corrosion/79, March 1979.

T. Johnson, A. Sagü’es, and B. Davis:Distillation Tower Corrosion: Synergistic Effects of Chlorine and Phenolic Compounds in Coal Liquids, Institute for Mining and Minerals Research, Lexington, Ky., IMMR48-PD23-80, March 1980.

J. A. McMaster: “Selection of Titanium for Petroleum Refinery Components,”Materials Performance, vol. 18, no. 4, 1979, p. 28.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Baylor, V.B., Keiser, J.R. Corrosion and stress corrosion cracking in coal liquefaction processes. JMES 2, 12–27 (1980). https://doi.org/10.1007/BF02833394

Issue Date:

DOI: https://doi.org/10.1007/BF02833394