Abstract

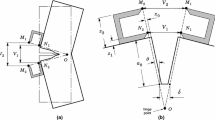

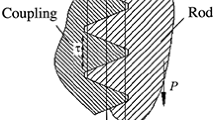

Failures of various types of hydraulic couplings used to connect pipes in a naval vessel are described and used to illustrate some of the general procedures for failure analysis. Cracking of couplings, which were manufactured from nickel-aluminum-bronze extruded bar, occurred in both seawater and air environments. Cracks initiated at an unusually wide variety of sites and propagated in either longitudinal or circumferential directions with respect to the axis of the couplings. Fracture surfaces were intergranular and exhibited little or no sign of corrosion (for couplings cracked in air), and there was very limited plasticity. Macroscopic progression markings were observed on fracture surfaces of several couplings but were not generally evident. At very high magnifications, numerous slip lines, progression markings, and striations were observed. In a few cases, where complete separation had occurred in service, small areas of dimpled overload fracture were observed. It was concluded from these observations, and from comparisons of cracks produced in service with cracks produced by laboratory testing under various conditions, that cracking had occurred by fatigue. The primary cause of failure was probably the unanticipated presence of high-frequency stress cycles with very low amplitudes, possibly due to vibration, resonance, or acoustic waves transmitted through the hydraulic fluid. Secondary causes of failure included the presence of high tensile residual stresses in one type of coupling, undue stress concentrations at some of the crack-initiation sites, and overtorquing of some couplings during installation. Recommendations on ways to prevent further failures based on these causes are discussed.

Similar content being viewed by others

References

D.A. Ryder, T.J. Davies, and I. Brough: “General Practice in Failure Analysis,”Failure Analysis and Prevention, Vol. 11, 9th ed.,ASM Handbook, ASM International, Materials Park, OH, 1986, pp. 15–46.

A.J. McEvily:Metal Failures: Mechanisms, Analysis, Prevention, John Wiley, 2002.

Anon.: D.G. Ships Procurement Specification 1043, Issue 03, “Nickel-Aluminium Forgings, Forging Stock, Rods and Sections,” MOD, U.K., Ships Dept., March 1981.

M. Sadayappan, R. Zavadil, and M. Sahoo: “Effect of Impurity Elements on the Mechanical Properties of Aluminium Bronze Alloy C95800,”Abstracts and Summaries of 8th CF/CRAD Meeting in Naval Applications of Materials Technology, Defence Research Establishment Atlantic, Special Report DREA SR 1999-162, Canada, 1999, pp. 221–34.

Anon.: ASTM B 154-89, “Standard Test Method for Mercurous Nitrate Test for Copper and Copper Alloys,” ASTM, Philadelphia, PA.

F. Hansan, A. Jahanafrooz, G.W. Lorimer, and N. Ridley: “The Morphology, Crystallography, and Chemistry of Phases in As-Cast Nickel-Aluminium Bronze,”Metall. Trans. A, 1982,13, pp. 1337–45.

A. Jahanafrooz, F. Hasan, G.W. Lorimer, and N. Ridley: “Microstructural Development in Complex Nickel-Aluminium Bronzes,”Metall. Trans. A, 1983,14, pp. 1951–56.

Failure Analysis and Prevention, Vol. 11, 9th ed.,ASM Handbook, ASM International, Materials Park, OH, 1998, p. 26.

Fractography, Vol. 12, 10th ed., ASM International, Materials Park, OH, 1999, p. 290.

R.N. Parkins, C.M. Rangel, and J. Yu:Metall. Trans. A., 1985,16, p. 1671.

E.J. Czyryca and R.B. Niederberger: “Mechanical, Fatigue and Corrosion Properties of Propeller Bronzes,”Propellers ’75, The Soc. of Naval Arch. and Marine Engs., New York, 1976.

B.F. Brown: “Stress-Corrosion Cracking Control Measures,”Copper Alloys, National Bureau of Standards, 1977.

R.N. Parkins and Y. Suzuki: “Environment-Sensitive Cracking of a Nickel-Aluminium-Bronze Under Monotonic and Cyclic Loading Conditions,”Corros. Sci., 1983,23, pp. 577–99.

R.D. Scheffel, M.A. Phoplonker, J. Byrne, R.L. Jones, and P. Barnes: “Sustained-Load Crack Growth in an Aluminium-Silicon Bronze Alloy,”Fracture Control of Engineering Structures, ECF 6, H.C. Van Elst and A. Bakker, Ed., EMAS, Amsterdam, 1986, pp. 1851–60.

J.W.H. Price, R.N. Ibrahim, and D. Ischko: “Sustained-Load Crack Growth Leading to Failure in Aluminium Gas Cylinders in Traffic,”Eng. Fail. Anal., 1997,4, pp. 259–70.

J.J. Lewandowski, V. Kohler, and N.J.H. Holroyd: “Effect of Lead on the Sustained-Load Cracking of Al-Mg-Si Alloys at Ambient Temperatures,”Mater. Sci. Eng., 1987,96, pp.185–95.

J.J. Lewandowski, Y.S. Kim, and N.J.H. Holroyd: “Lead-Induced Solid-Metal Embrittlement of an Excess Silicon Al-Mg-Si Alloy at Temperatures of −4°C to 80°C,”Metall. Trans. A, 1992,23, pp. 1679–89.

S.E. Stanzl and H.M. Ebenberger: “Concepts of Fatigue Crack Growth Thresholds Gained by the Ultrasound Method,”Fatigue Crack Growth Threshold Concepts, D.L. Davidson and S. Suresh, Ed., Met. Soc. AIME, 1984, pp. 399–416.

M.A. Phoplonker, J. Byrne, T.V. Duggan, R.D. Scheffel, and P. Barnes: “Near-Threshold Fatigue Crack Growth in an Aluminium Bronze Alloy,”Int. Conf. on Fatigue of Engineering Materials and Structures, Vol. 1, Inst. of Mechanical Engineers, London, 1986, pp. 137–44.

Metal Fatigue, G. Simes and J.L. Waisman, Ed., McGraw-Hill, London, 1959, p. 11.

S. Finnvedan, “Simplified Equations of Motion for the Radial-Axial Vibrations of Fluid-Filled Pipes,”J. Sound Vib., 1997,208, pp. 685–703.

J.K. Smith, P.C. Riccardella, and S.R. Gosselin: “Development of a Screening Procedure for Vibrational Fatigue in Small-Bore Piping,”Int. Pressure Vessels and Piping Codes and Standards, Vol. 2, Current Perspectives, PVP-Vol. 313-2, ASME, 1995, pp. 67–74.

F.L. Eisinger: “Designing Piping Systems Against Acoustically Induced Structural Fatigue,”Flow-Induced Vibration, PVP-Vol. 328, ASME, 1996, pp. 397–404.

K.J. Miller and W.J. O’Donnell: “The Fatigue Limit and its Elimination,”Fatigue Fract. Eng. Mater. Struct., 1999,22, pp. 545–57.

C. Bathias, L. Drouillac, and P.Le. Francois: “How and Why the Fatigue S-N Curve Does Not Approach a Horizontal Asymptote,”Int. J. Fatigue, 2001,23, pp. S143-S151.

B. Wallen and T. Andersson: “Galvanic Corrosion of Copper Alloys in Contact with Highly Alloyed Stainless Steel in Seawater,” Avesta Corrosion Management, Avesta AB, Avesta Acom No. 2-1987.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lynch, S.P., Edwards, D.P., Nethercott, R.B. et al. Failure of nickel-aluminum-bronze hydraulic couplings, with comments on general procedures for failure analysis. Practical Failure Analysis 2, 50–61 (2002). https://doi.org/10.1007/BF02715500

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02715500