Abstract

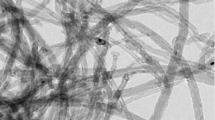

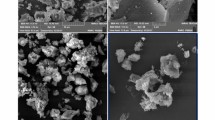

Mullite-SiC nanocomposites are synthesized by introducing surface modified sol-gel mullite coated SiC particles in the matrix and densification and associated microstructural features of such precursor are reported. Nanosize SiC (average size 180 nm) surface was first provided with a mullite precursor coating which was characterized by the X-ray analysis and TEM. An average coating thickness of 120 nm was obtained on the SiC particles. The green compacts obtained by cold isostatic pressing were sintered in the range 1500–1700°C under pressureless sintering in the N2 atmosphere. The percentage of the theoretical sintered density decreases with increase in SiC content. A maximum sintered density of 97% was achieved for mullite-5 vol.% SiC. The fractograph of the sintered composite showed a highly dense, fine grained microstructure with the SiC particles uniformly distributed along the grains as well as at the grain boundaries inside the mullite. The Vicker’s microhardness of mullite-5 vol.% SiC composite was measured as 1320 kg/mm2 under an applied indentation load of 500 g. This value gradually decreased with an increase in SiC content.

Similar content being viewed by others

References

Bhaduri S and Bhaduri S B 1998J. Mater. 1 44

Choa Y H, Niihara A and Niihara K 1994J. Am. Ceram. Soc. 77 3259

Hu C L and Rahaman M N 1992J. Am. Ceram. Soc. 75 2056

Hu C L and Rahaman M N 1993J. Am. Ceram. Soc. 76 2549

Kanpuri N, Rai K N and Upadhyaya G S 1996Ceram. Int. 106 14

Kapolnek D and De Jonghe L C 1991J. Eur. Ceram. Soc. 7 345

Komerneni S 1992J. Mater. Chem. 2 1219

Mitchell T D and De Jonghe L C 1995J. Am. Ceram. Soc. 78 199

Niihara K 1991J. Ceram. Soc. Jpn. 99 974

Pezzotti G and Saki M 1994J. Am. Ceram. Soc. 77 3039

Saka Y, Bidinger D D and Aksay I A 1995J. Am. Ceram. Soc. 78 479

Thompson A M, Chan H M, Harmer M P and Cook R F 1995J. Am. Ceram. Soc. 78 567

Warrier K G K, Hareesh U S, Anil Kumar G M and Damodaran A D 1996Ceram. Trans. 68 251

Wang C M 1996J. Mater. Sci. 31 4709

Wang J, Ponton C B and Marquis P M 1996Scr. Mater. 34 935

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Warrier, K.G.K., Kumar, G.M.A. & Ananthakumar, S. Densification and mechanical properties of mullite-SiC nanocomposites synthesized through sol-gel coated precursors. Bull Mater Sci 24, 191–195 (2001). https://doi.org/10.1007/BF02710100

Issue Date:

DOI: https://doi.org/10.1007/BF02710100