Abstract

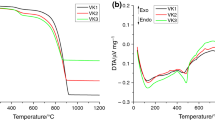

The sintering of lime by double calcination process from natural limestone has been conducted with La2O3 and CeO2 additive up to 4 wt.% in the temperature range 1500–1650° C. The results show that the additives enhanced the densification and hydration resistance of sintered lime. Densification is achieved up to 98.5% of the theoretical value with La2O3 and CeO2 addition in lime. Grain growth is substantial when additives are incorporated in lime. The grain size of sintered CaO (1600°C) with 4 wt.% La2O3 addition is 82 μm and that for CeO2 addition is 50 μm. The grains of sintered CaO in presence of additive are angular with pores distributed throughout the matrix. EDX analysis shows that the solid solubility of La2O3 and CeO2 in CaO grain is 2.9 and 1.7 weight %, respectively. The cell dimension of CaO lattice is 4.803 %C. This value decreases with incorporation of La2O3 and CeO2. The better hydration resistance of La2O3 added sintered lime compared to that of CeO2 added one, is related to the bigger grain size of the lime in former case.

Similar content being viewed by others

References

Boynton R S 1980Chemistry and technology of lime and limestone (New York: John Wiley and Sons) p. 18

Bratschun W R 1962J. Am. Ceram. Soc. 45 611

Brezny B 1976J. Am. Ceram. Soc. 59 529

Carr K, Evans L J, Leonard L A and Richardson 1968Trans. Br. Ceram. Soc. 64 473, 493

Ghoneim N H, Mandour M A and Serry M A 1989Ceram. Int. 15 357

Ghosh A, Bhattacharya T K, Mukherjee B and Das S K 2001Ceram. Int. 27 201

Gropyanov V M and Novikov V L 1923Ogneupory 9 11

Harkulich T M, Magder J, Vukasovich M S and Lockhart R J 1966J. Am. Ceram. Soc. 49 295

Heslop R B and Jones K 1976Inorganic chemistry, A guide to advanced study (Amsterdam: Elsevier Scientific Publishing Co.)

Hubble D H 1969J. Am. Ceram. Soc. Bull. 48 618

Nadachowski F 1975Interceram 24 42

Nadachowski F 1976Ceramurgia Int. 2 55

Petersen R O and Cutler IB 1968J. Am. Ceram. Soc. 51 21

Samsonov G V 1973The oxide hand book (New York: Plenum Press) 2nd ed. p. 178

Shi Ying-Yi, Messing G L and Bradt R C 1984J. Am. Ceram. Soc. 67 C-109

White J 1972Bol. Soc. ESP Ceram. 11 11

Williams P, Sunderlan M and Briggs G 1982Iron Making & Steel Making 9 150

Wong L Lana and Bradt C Richard 1995J. Am. Ceram. Soc. 78 1611

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bhattacharya, T.K., Ghosh, A., Tripathi, H.S. et al. Solid state sintering of lime in presence of La2O3 and CeO2 . Bull Mater Sci 26, 703–706 (2003). https://doi.org/10.1007/BF02706767

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02706767