Abstract

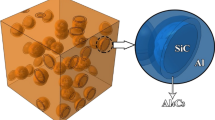

In this paper, two and three-dimensional clustering models are developed to characterize the effect of nano-particle clustering on toughening of nanocomposite ceramics. It is found that crack pinning toughens the nano-composite ceramics because a higher stress intensity factor is needed for crack to propagate around or to pull-out the nano-particle. The nano-particle along the grain boundary steers the crack into the matrix grain due to the strong cohesion between the nanoparticle and the matrix. Since the fracture resistance of the grain boundary is lower than that of the grain lattice, the higher the probability of transgranular fracture induced by nano-particles, the tougher is the nano-composite. However, both crack pinning and transgranular fracture are affected by nano-particle clustering. Nanoparticle clustering, which increases with increasing volume fraction of nano-particles, leads to reduction of both the strength and toughness of the nano-composite ceramics. The larger the size of the clustered particle, and the more defects it contains, the easier it is for the crack to pass through the clustered particle, which means that the nano-particle clustering can reduce toughening induced by crack pinning and transgranular fracture. The theoretical prediction, based on the combination of the three mechanisms of nano-particles, is in agreement with the experimental data.

Similar content being viewed by others

References

Izaki K, Hakkei K, Ando K. Ultrastructure processing for advanced ceramics. New York: John Willey & Sons, 1988. 981–990

Niihara K, Nakahira A. Particulate strengthened oxide nanocomposites. In: Vincenzini P ed. Advanced Structural Inorganic Composites. Trieste: Elsevier Scientific Publishing Co, 1990. 637–664

Niihara K. New design concept of structural ceramics-ceramic nanocomposites. The centennial issue of the Ceramic Society of Japan,J Ceram Soc of Jpn, 1991, 99(10): 962–974

Niihara K, Suganuma K, Nakahira A, et al. Interfaces of Si3N4/SiC nano-composites.J Mater Sci Let, 1990, 9: 598–599

Niihara K, Unal N, Nakahira A. Mechanical properties of (Y-TZP)-alumina-silicon carbide nanocomposites and the phase stability Y-TZP particles in it.J Mater Sci, 1994, 29: 164–168

Sawaguchi A, Toda K, Niihara K. Mechanical and electrical properties of nano-composites.J Am Ceram Soc, 1991, 74: 1142–1144

Zhao J, Stearns LC, Harmer MP, et al. Mechanical behavior of Alumina-silicon carbide “nanocomposite”J Am Ceram Soc, 1993, 76(2): 225–240

Levin I, Kaplan WD, Brandon DG, et al. Residual stresses in Alumina-SiC nanocomposites.Acta Metall Mater, 1994, 42(4): 1147–1154

Sato S, Chu MC, Kim JH, et al. Influence of SiC particle size on microstructure and mechanical properties of Si3N4/SiC composite ceramics.J Ceramic Soc of Jpn, 1996, 103: 667–670

Tian W, Zhou Y, Zhou WL. SiC nano-particle reinforced Si3N4 matrix composites.J Mat Sci, 1998, 33: 797–802

Tan HL, Yang W. Toughening mechanisms of nano-composite ceramicsMechanics of Materials, 1998, 30: 111–123

Hwang KT, Kim CS, Auh KH, et al. Influence of SiC particle size and drying method on mechanical properties and microstructure of Si3N4/SiC nano-composites.Materials Letters, 1997, 132: 251–257

Pezzotti G, Nishida T, Sakai M. Physical limitations of the inherent toughness and strength in ceramic-ceramic and ceramic-metal nano-composites.J Ceramic Soc of Jpn, 1996, 103: 889–896

Pezzotti G, Nishida T, Sakai M. Reply to “Comments on ‘Physical limitations of the inherent toughness and strength in ceramic-ceramic and ceramic-metal nano-composites‘’.J Ceramic Soc of Jpn, 1997, 104: 557–558

Ortize M, Phillips R. Nanomechanics of defects in solids.Advances in Applied Mechanics, 1999, 36: 1–79

Tszeng TC. The effects of particle clustering on the mechanical behavior of particle reinforced composites.Composites Part B, 1998, 29B: 299–308

Hu GK, Guo G, Baptiste D. A micromechanical model of influence of particle fracture and particle cluster on mechanical properties of metal matrix composites.Computational Materials Science, 1998, 9: 420–430

Estevez R, Maire E, Franciosi P, et al. Effect of particle clustering on the strengthening versus damage rivalry in particulate reinforced elastoplastic materials: A 3D analysis from a self-consistent modeling.Eur J Mech A/Solids, 1999, 18: 785–804

Gauckler KJ, Graule TJ. Swiss Patent 1992, No.02377/92-1

Lawn BR, Evans AG, Marshall DB. Elastic/plastic indentation damage in ceramics: The median/radial crack system.J Am Ceram Soc, 1980, 62: 574–581

Toya M. A crack along the interface of a circular inclusion embedded in an infinite solidJ Mech Phys Solids, 1972, 22: 325–348

Cotterell B, Rice JR. Slightly curved or kinked cracks.Int J Fract, 1980, 116: 155–169

Sumi Y. Energy consideration on branched and curved crack extension. In: Weng GJ, et al. eds. Micromechanics and Inhomogeneity (Toshio Mura's anniversary volume). Berlin: Springer, 1989. 407–419

Sumi Y. A second order perturbation solution of a non-collinear crack and its application to crack path prediction of brittle fracture in weldment. Naval Architect.Ocean Eng, 1992, 28: 143–156

McColm IJ. Ceramic Hardness, New York: Plenum Press, 1990

Author information

Authors and Affiliations

Additional information

The project supported by the National Natural Science Foundation of China (19891180) and the Research Grants Council of the HKSAR, China(HKU7081/00E)

Rights and permissions

About this article

Cite this article

Zhaoxu, D., Daining, F. & Kah, S.A. On the effect of nano-particle clustering on toughening of nano-composite ceramics. Acta Mech Sinica 18, 146–158 (2002). https://doi.org/10.1007/BF02487469

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02487469