Abstract

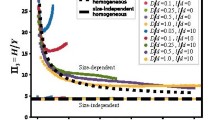

Micro-indentation tests at scales of the order of sub-micron show that the measured hardness increases strongly with decreasing indent depth or indent size, which is frequently referred to as the size effect. At the same time, at micron or sub-micron scale, another effect, which is referred to as the geometrical size effects such as crystal grain size effect, thin film thickness effect, etc., also influences the measured material hardness. However, the trends are at odds with the size-independence implied by the conventional elastic-plastic theory. In the present research, the strain gradient plasticity theory (Fleck and Hutchinson) is used to model the composition effects (size effect and geometrical effect) for polycrystal material and metal thin film/ceramic substrate systems when materials undergo micro-indenting. The phenomena of the “pile-up” and “sink-in” appeared in the indentation test for the polycrystal materials are also discussed. Meanwhile, the micro-indentation experiments for the polycrystal Al and for the Ti/Si3N4 thin film/substrate system are carried out. By comparing the theoretical predictions with experimental measurements, the values and the variation trends of the micro-scale parameter included in the strain gradient plasticity theory are predicted.

Similar content being viewed by others

References

Nix WD, Gao H. Indentation size effects in crystalline materials: a law for strain gradient plasticity.J Mech Phys Solids, 1998, 46(3): 411–425

McElhaney KW, Vlassak JJ, Nix WD. Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments.J Mater Res, 1998, 13(5): 1300–1306

Begley M, Hutchinson JW. The mechanics of size-dependent indentation.J Mech Phys Solids, 1998, 46(3): 2049–2068

Shu JY, Fleck NA. The prediction of a size effect in micro-indentation.Int J Solids Structures, 1998, 35(13): 1363–1383

Poole WJ, Ashby MF, Fleck NA. Micro-hardness tests on annealed and work-hardened copper polycrystals.Scripta Metall Mater, 1996, 34(6): 559–564

Atkinson M. Further analysis of the size effective in indentation hardness tests of some metals.J Mater Res, 1995, 10(12): 2908–2915

Ma Q, Clarke DR. Size dependent hardness of silver single crystals.J Mater Res, 1995, 10(4): 853–863

Stelmashenko NA, Walls MG, Brown LM, et al. Microindentation on W and Mo priented single crystals: an STM study.Acta Metall Mater, 1993, 41(10): 2855–2865

Wei Y, Wang X, Wu X, et al. Theoretical and experimental researches of size effect in micro-indentation test.Science in China (Series A), 2001, 44(1): 74–82

Cheng YT, Cheng CM. Scaling relationships in conical indentation of elastic-perfectly plastic solids.Int J Solids Structures, 1999, 36(5): 1231–1243

Fleck NA, Hutchinson JW. Strain gradient plasticity.Advances in Applied Mechanics, 1997, 33: 295–361

Gao H, Huang Y, Nix WD, et al. Mechanism-based strain gradient plasticity—I: Theory.J Mech Phys Solids, 1999, 47(6): 1239–1263

Aifantis EC. On the microstructural origin of certain inelastic models.Trans ASME J Eng Mater Tech, 1984, 106(3): 326–330

Wei Y, Hutchinson JW. Steady-state crack growth and work of fracture for solids characterized by strain gradient plasticity.J Mech Phys Solids, 1997, 45(8): 1253–1273

Timoshenko SP, Goodier JN. Theory of Elasticity. Third edition. New York: McGraw-Hill, Inc, 1970. 401

Shaw MC. In: McClintock FA, Argon AS, eds. Mechanical Behavior of Materials. Reading: Addison-Wesley, Mass, 1966. 443

Hill R. Continuum micro-mechanics of elastoplastic polycrystals.J Mech Phys Solids, 1965, 13(1): 89–101

Xia ZC, Hutchinson JW. Crack tip fields in strain gradient plasticity.J Mech Phys Solids, 1996, 44: 1621–1648

Chen JY, Wei Y, Huang Y, et al. The crack tip fields in strain gradient plasticity: the asymptotic and numerical analyses.Eng Fract Mech, 1999, 64: 625–648

Wei Y. Particulate size effects in the particle-reinforced metal matrix composites.Acta Mechanica Sinica, 2001, 17(1): 45–58

Author information

Authors and Affiliations

Additional information

The project supported by the National Natural Science Foundation of China (19891180 and 19925211) and Bai Ren Plan of CAS

Rights and permissions

About this article

Cite this article

Yueguang, W., Xuezheng, W., Manhong, Z. et al. Size effect and geometrical effect of solids in micro-indentation test. Acta Mech Sinica 19, 59–70 (2003). https://doi.org/10.1007/BF02487454

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02487454