Abstract

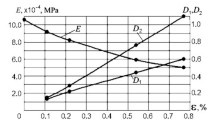

In this paper the method of damage measurement of metal structure at the creep is proposed. In contrast to other methods, it allows the measurement of this damage to be carried out in the process of creep test without unloading and cooling of specimens. Experimental damage curves during creep are obtained as a result of test data processing by the suggested method. The analysis of these curves leads to a conclusion that the material damage at repture is monotonically decreasing function of the applied stress. This conclusion is an experimental verification of the theoretical result, obtained earlier.

Similar content being viewed by others

References

Kachanov L. M., O vermeni razrusheniya v usloviyah polzuchesti, Izv. AN SSSR, Otdel. tehn. nauk, 8(1958), 26–31, (in Russian).

Rabotnov Yu. N., O mehanizme dliteinogo razrusheniya, v sbornike, Voprosi porchnosti materialov i konstrukcii, Izdat. AN SSSR,M., (1959), 5–7 (in Russian).

Rabotnov Yu. N., Polzuchest elementov konstrukcii. M., Nauka, 752str, (1966), (in Russian, translated into English).

Shesterikov S. A., Lokochtchenko A. M., Polzuchest i dlitelnaya prochnost metallov, Itogi nauki i tehniki. Ser. Mehan. deform. tverd. tela, Tom 13. Vses. inst. nauchn. i tehn. inform. M., (1980), 3–104 (in Russian).

Polzuchest i dlitelenaya prochnost elementov konstrukcii, Bibliogr. ukazatel (red.-Nikitenko A. F.), Sib. Otdel. AN SSSR,Novosibirsk, 342 str. (1987), (in Russian).

Lemaitre J., Damage modelling for prediction of plastic or creep fatigue failure in structures,Acta mechanica solida sinica,4(1981), 512–525 (in Chinese).

Shen Huairong. On nonlinear constitutive equation for visco-elastic damage media and dewetting damage model for highly filled polymers.Acta mechanica solida sinica, 1(1987), 41–47 (in Chinese).

Horiguhi M., Kawasaki T., Creep rupture of stainless steels at high temperatures, J. Jap. Soc., Strength and Fract. Mat.,12, 1(1977), 34–43 (in Japan).

Dyson B. F., Taplin D. M. R. Creep damage accumulation, Grain Bound. Inst. Met. Spring Resident. Conf., Ser. 3, (1976), london, s.a., E/23-E/28.

Biedel H., The extension of a macroscopic crack at elevated temperature by the growth and coalescence of microvoids, Creep in structures Proc. III IUTAM Symp. Leicester. 8–12. IX. 1980. Berlin e. a., (1981), 504–515.

Leckie F. A., Hayhurst D. R., Constitutive equations for creep rupture,Acta Met., 1977,25, 1059–1070.

Lokochtchenko A. M., Investigation of material damage under creep and creep strength. Prikl. mekhan. i tekhn. fiz., 6(1982) 129–133 (in Russian, translated into English).

Nigmatulin R. I., Holin N. N., Dislokacionnaya kinetika sverkhplastichnosti i polzuchestic metallov. Dokl. AN SSSR,231, 2(1976), 303–306 (in Russian).

Estrin Y., Mecking H. A unified phenomenological description of work hardening and creep, based on one-parameter models.Acta Met.,32, 1(1984), 57–70.

Rozenberg V. M., Shalimova A. V., Zvereva T. S., Vliyanie temperaturi i napryazenii na obrazovanie por pri polzuchesti, Fiz. met. i metalloved.,25,2(1968) 326–332(in Russian).

Cane B. F., Deformation, induced intergranular creep cavitation in alphairon,Metal. Sci. 12, 2 (1978), 102–108.

Betehtin V. I., Kadomcev A. G., Petrov A. I., Osobennosti mikrorazrusheniya metallov pri visokotemperaturnoi polzuchesti, Metalloved. i termich. obrab. met., 12(1980), 24–26 (in Russian).

Arutyunyan R. A., O vzaimosvyazi reollogii i razrusheniya polimernikh materialov,Mekh. kompoz. mater.,4, (1983) 583–586 (in Russian).

Kumanin V. I., Trunin I. I., Bogomolnaya R. B., Izychenie processa nakopleniya povrezdaemosti v usloviyakh visokotemperaturnoi polzuchesti. Nauchn. trudi Vses. zaochn. mashinostr. inst.,1, (1973) 55–65 (in Russian).

Belloni G., Bernasconi G. Creep damage models. Creep Eng. Mater. and Structure. Proc. Semin. Ispra (Varese), (1978). London, (1979), 195–227.

Shesterikov S. A., Lokochtchenko A. M., Myakotin E. A., Use of the method of measuring electrical resistance in studying the strength and creep of metals. Probl. prochn., AN UkrSSR, 10 (1984), 32–35 (in Russian, translated into English).

Broberg H. A new criterion for brittle rupture.J. Appl. Mech.,41, 3(1974), 809–811.

Boström P. O., Broberg H., Bräthe L., Chrzanowski M. On failure conditions in viscoelastic media and structures, Int. Symp. on mechanics of viscoelastic media and bodies, Gothenburg, Sept. (1974) 2–6. Springer-Verlag, Berlin (1975), 302–311.

Dacheva M. D., Lokochtchenko A. M., Shesterikov S. A., Model representation of the ultimate strain during creep. Prikl. mekhan. i tekhn. fiz., Sib. Otdel. AN SSSR,4(1984), 139–142 (in Russian, translated into English).

Author information

Authors and Affiliations

Additional information

Visiting scholar (1988–1989) at South China University of Technology

Rights and permissions

About this article

Cite this article

Lokochtchenko, A.M. The investigation of the metal damage at the creep by the method of electrical resistance measuring. Acta Mech Sinica 7, 157–161 (1991). https://doi.org/10.1007/BF02486843

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02486843