Abstract

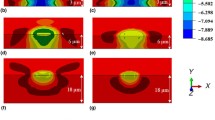

The interface adhesion strength (or interface toughness) of a thin film/substrate system is often assessed by the micro-scratch test. For a brittle film material, the interface adhesion strength is easily obtained through measuring the scratch driving forces. However, to measure the interface adhesion strength (or interface toughness) for a metal thin film material (the ductile material) by the micro-scratch test is very difficult, because intense plastic deformation is involved and the problem is a three-dimensional elastic-plastic one. In the present research, using a double-cohesive zone model, the failure characteristics of the thin film/substrate system can be described and further simulated. For a steady-state scratching process, a three-dimensional elastic-plastic finite element method based on the double cohesive zone model is developed and adopted, and the steady-state fracture work of the total system is calculated. The parameter relations between the horizontal driving forces (or energy release rate of the scratching process) and the separation strength of thin film/substrate interface, and the material shear strength, as well as the material parameters are developed. Furthermore, a scratch experiment for the Al/Si film/substrate system is carried out and the failure mechanisms are explored. Finally, the prediction results are applied to a scratch experiment for the Pt/NiO material system given in the literature.

Similar content being viewed by others

References

Blees MH, Winkelman GB, Balkenende AR, et al. The effect of friction on scratch adhesion testing: application to a sol-gel coating on polypropylene.Thin Solid Films, 2000, 359(1): 1–13

Pistor C, Friedrich K. Scratch and indentation tests on polyoxymethylene (POM).J Appl Polymer Science, 1997, 66(9): 1985–1996

Bull SJ. Failure modes in scratch adhesion testing.Surface & Coatings Tech, 1991, 50(1): 25–32

Maekawa H, Ikeda T, Horibe H, et al. On the scratch pattern of evaporated thin metal film.Quart J Japan Welding Society, 1994, 12(2): 262–268

Dutta I, Campbell JC. Determination of the adhesive strength of film-substrate interface using the constant depth scratch test.Mater Res Soc Symp Proc, 1995, 390(1): 49–54

Venkataraman S, Kohlstedt DL, Gerberich WW. Continuous microscratch measurements of the practical and true works of adhesion for metal/ceramic systems.J Mater Res, 1996, 11(12): 3133–3145

Jardret V, Zahouani H, Loubet JL, et al. Understanding and quantification of elastic and plastic deformation during a scratch test.Wear, 1998, 218(1): 8–14

Yamamoto S, Ichimura H. Effects of intrinsic properties of TiN coating on acoustic emission behavior at scratch test.J Mater Res, 1992, 7(11): 2240–2247

Thouless MD. An analysis of spalling in the microscratch test.Eng Frac Mech, 1998, 61(1): 75–81

Tvergaard V, Hutchinson JW. The relation between crack growth resistance and fracture process parameters in elastic-plastic solids.J Mech Phys Solids, 1992, 40(6): 1377–1397

Tvergaard V, Hutchinson JW, The influence of plasticity on mixed mode interface toughness.J Mech Phys Solids, 1993, 41(6): 1119–1135

Beltz GE, Rice JR, Shih CF, et al. A self-consistent model for cleavage in the presence of plastic flow.Acta Mater, 1996, 44(10): 3943–3954

Wei Y, Hutchinson JW. Nonlinear delamination mechanics for thin films.J Mech Phys Solids, 1997, 45(7): 1137–1159

Wei Y, Hutchinson JW. Interface strength, work of adhesion and plasticity in the peel test.Int J Fracture, 1998, 93(1–4): 315–333

Needleman A. A continuum model for void nucleation by inclusion debonding.J Applied Mechanics, 1987, 54(3): 525–531

Suo Z, Shih CF, Varias AG. A theory for cleavage cracking in the presence of plastic flow.Acta Metall Mater, 1993, 41(5): 1551–1557

Wei Y, Hutchinson JW. Models of interface separation accompanied by plastic dissipation at multiple scales.Int J Fracture, 1999, 95(1): 1–17

Hutchinson JW. On steady quasi-static crack growth. Harvard University Report DEAP S-8 (AFSOR-TR-74-1042), 1974

Dean RH, Hutchinson JW. Quasi-static steady crack growth in small scale yielding. In: Fracture Mechanics. Philadelphia: ASTM STP700, 1980. 383–405

Wei Y. Microscale mechanics for metal thin film delamination along ceramic substrates.Science in China (Series A), 2000, 43(5): 509–516

Fleck NA, Hutchinson JW. Strain gradient plasticity. In: Hutchinson JW et al. eds. Advances in Applied Mechanics. New York: Academic Press, 1997, 33: 295–361

Gao H, Huang Y, Nix WD, et al. Mechanism-based strain gradient plasticity: I. Theory.J Mech Phys Solids, 1999, 47(6): 1239–1263

Huang Y, Gao H, Nix WD, et al. Mechanism-based strain gradient plasticity: II. Analysis.J Mech Phys Solids, 2000, 48(1): 99–128

Chen S, Wang TC. A new hardening law for strain gradient plasticity.Acta Mater, 2000, 48(16): 3997–4005

Wei Y, Hutchinson JW. Steady-state crack growth and work of fracture for solids characterized by strain gradient plasticity.J Mech Phys Solids, 1997, 45(8): 1253–1273

Author information

Authors and Affiliations

Additional information

The project supported by the National Natural Science Foundation of China (19891180 and 19925211) and Bai Ren Plan of CAS

Rights and permissions

About this article

Cite this article

Yueguang, W., Manhong, Z. & Shan, T. Characterization of the fracture work for ductile film undergoing the micro-scratch. Acta Mech Sinica 18, 494–505 (2002). https://doi.org/10.1007/BF02486574

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02486574