Abstract

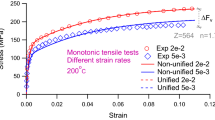

Some improvements in Jin's thermal visco-plastic constitutive model considering dynamic recrystallization is presented in this paper. By introducing the influence of the strain rate on the mobility of dynamic recovery, the improved model can be more smoothly applied to numerical simulation of material flow behaviour and microstructure prediction during hot working. Another improvement is to consider the accumulated dislocation energy in the newly recrystallized grains as a resistance to the driving force of dynamic recrystallization volume. This improvement makes the predicted results of dynamic recrystallization progress agree better with the actual physical process. Finally, some numerical examples are given to show the advantages of the improved model and the ability to predict the dynamic recrystallization.

Similar content being viewed by others

References

Roberts W. Dynamic changes that occur during hot working and their significance regarding microstructural development and hot workability. In: Krauss G ed. Deformation, Processing and Structure: Papers Presented at the 1982 ASM Materials Science Seminar. The Metallurgical Society of AIME. 1982. 109–184

Karhausen K, Kopp K. Model for integrated process and microstructure simulation in hot forming.Steel Res, 1992, 63: 247–258

Busso EP. A continuum theory for dynamic recrystallization with microstructure-related length scales.Int J Plast, 1998, 14: 319–353

Jin QL. A new analytical model of dynamic recrystallization.Journal of Plasticity Engineering, 1994, 1: 3–13 (in Chinese)

Sandström R, Langeborg R. A model for hot working occurring by recrystallization.Acta Metall, 1975, 23: 387–398

Roberts W, Ahlblom B. A nucleation criterion for dynamic recrystallization during hot working.Acta Metall, 1978, 26: 801–813

Mcqueen HJ, Ryan ND. Constitutive analysis in hot working.Mater Sci Eng A, 2002, 322: 43–63

Morris C. Self-diffusion during plastic deformation.Trans JIM, 1970, 11: 145–151

Pan JS, Tong JM, Tian MB. Material Science Foundation. Beijing: Tsinghua University Press, 1998 (in Chinese)

Wang GF, Yu SW, Feng XQ. Boundary layers near interfaces between crystals with strain gradient effects.Mech Res Communication, 2001, 28: 87–95

Wang GF, Feng XQ, Yu SW. Interface effects on effective elastic moduli of nanocrystalline materials.Mater Sci Eng A, 2003, 363: 1–8

Mcqueen HJ. Initiating nucleation of dynamic recrystallization, primarily in polycrystals.Mater Sci Eng A, 1988, 101: 149–160

Venugopal S, Mannan SL. On the modelling of Grain Size during hot working of stainless steels type AISI 304 and 316.J Mater Sci Lett, 1997, 16: 137–142

Xu FJ. Research on processing property of low pressure turbine rotor steel. [Master thesis], Beijing: Beijing Research Institute of Mechanical and Electrical Technology, 1998

Mcqueen HJ. Initiating nucleation of dynamic recrystallization, primarily in polycrystals.Mater Sci Eng A, 1988, 101: 149–160

Venugopal S, Mannan SL. On the modelling of Grain Size during hot working of stainless steels type AISI 304 and 316.J Mater Sci Lett, 1997, 16: 137–142

Brown SB, Kim KH, Anand L. An internal variable constitutive model for hot working of metals.Int J Plast, 1989, 5: 95–130

Sakai T, Jonas JJ. Dynamic recrystallization: mechanical and microstructural considerations.Acta Metall, 1984, 32: 189–205

Author information

Authors and Affiliations

Additional information

The project supported by the National Key Basic Research Development Plan (973 Planning) of Ministry of Science and Technology of China (G2000067200)

Rights and permissions

About this article

Cite this article

Jie, Q., Quanlin, J. & Bingye, X. Some improvements in visco-plastic model considering dynamic recrystallization. Acta Mech Sinica 20, 499–506 (2004). https://doi.org/10.1007/BF02484272

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02484272