Abstract

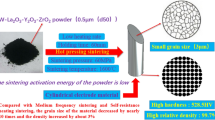

The Al2O3-ZrO2 eutectic composition was rapidly solidified, forming amorphous and crystalline structures. The as-quenched material was crushed and pressed into pellets which were sintered conventionally or with microwaves. Conventional and microwave sintering at temperatures up to 1600 °C resulted in a microstructure where 100–200 nm ZrO2 grains were present intergranularly in the α-Al2O3 grains. Larger ZrO2 grains (∼1 μm) were found intergranularly. The as-quenched lamellar structure spheroidized during sintering at high temperatures. Boron contamination of the powders resulted in more homogeneous and dense as-fired samples but promoted the ZrO2 tetragonal-to-monoclinic transformation, which was attributed to increased grain boundary diffusivity. Conventional sintering at low temperatures resulted in the formation of “rods” of an Al2O3-rich phase which grew from a low-melting B2O3-rich liquid.

Article PDF

Similar content being viewed by others

References

P. Duwez, R. H. Willens andW. Klement,J. Appl. Phys. 31 (1960) 1136.

P. T. Sargeant andR. Roy,J. Amer. Ceram. Soc. 50 (1967) 500.

M. C. Brockway andR. R. Wills, “Rapid Solidification of Ceramics — A Technology Assessment”, Metals and Ceramics Information Center Report MCIC 84–49 (Battelle Columbus Laboratories, Columbus, Ohio, 1984).

A. Revcolevschi andJ. Livage, in “Treatise on Materials Science and Technology”, Vol. 20, edited by H. Herman (Academic, New York, 1981) p. 73.

J. D. Katz andR. D. Blake,Ceram. Bull. 70 (1991) 1304.

J. Eastman, K. Sickafus, J. Katz, S. Boeke, R. Blake, C. Evans, R. Schwarz andY. Liao,Mater. Res. Soc. Symp. Proc. 189 (1991) 273.

J. McKittrick, G. Kalonji andT. Ando,J. Non-Cryst. Solids 94 (1987) 163.

T. Whitney, V. Jayaram, C. G. Levi, andR. Mehrabian, in “Solidification Processing of Eutectic Alloys”, edited by D. M. Stefanescu, G. J. Abbaschian and R. FJ. Bayuzick (Metallurgical Society, Warrendale, PA, 1988) p. 199.

N. Claussen, G. Lindemann andG. Petzow,Ceram. Int. 9 (3) (1983) 83.

P. J. M. Gielisse andW. R. Foster,Nature 195 (1962) 70.

L. A. Xue andI. W. Chen,J. Amer. Ceram. Soc. 74 (1991) 2011.

R. C. Garvie, R. H. J. Hannink andM. V. Swain,J. Mater. Sci. Lett. 11 (1983) 437.

B. N. Claussen andM. Rühle,Adv. Ceram. 3 (1981) 137.

R. C. Buchanan andC. M. Wilson,Gov. Rep. Announce. Index 85 (8) (1985) 111.

M. P. Harmer, in “Structure and Properties of MgO and Al2O3 Ceramics”, Advances in Ceramics, Vol. 10, edited by W. D. Kingery (American Ceramic Society, Columbus, OH, 1984) p. 679.

A. Heuer, N. Claussen, W. M. Kriven andM. Rühle,J. Amer. Ceram. Soc. 65 (1982) 642.

J. Baumard andP. Abelard, in “Advances in Ceramics”, Vol. 12, edited by N. Claussen, M. Rühle and A. Heuer (American Ceramic Society, Columbus, Ohio, 1984) p. 555.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McKittrick, J., Tunaboylu, B. & Katz, J. Microwave and conventional sintering of rapidly solidified Al2O3-ZrO2 powders. J Mater Sci 29, 2119–2125 (1994). https://doi.org/10.1007/BF01154689

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01154689