Abstract

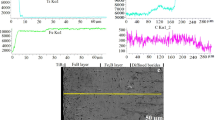

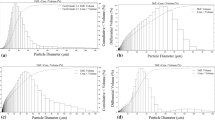

Contamination with copper particles of the surfaces of rapidly solidified Mg-3.5 wt% Al alloy splats during processing is discussed. Two batches of splats produced with copper substrates of different surface finish, were examined by atomic absorption spectrometry (AAS), electron probe micro-analysis (EPMA) and Rutherford back scattering (RBS). Lower copper content was detected on the well-polished splats (splats B) by AAS, while EPMA and RBS analysis with a micro-beam showed fine copper particles on the surfaces of the splats prepared with pistons of inferior surface finish (splats A). Immersion corrosion tests carried out in a 3% NaCl solution saturated with Mg(OH)2 resulted in higher pit density and earlier pitting times for splats A. Pitting is associated with copper particles (splats A) and with surface cracks and macro-porosity (splats A and B). A mechanism for pitting is suggested in which Mg(OH)Cl is envisaged to be an intermediate reaction product before decomposing to Mg(OH)2 in the pitting process.

Similar content being viewed by others

References

K. N. Reichek, K. J. Clark and J. E. Hillis, SAE Technical Paper, No. 850417, March, 1985.

J. D. Hanawalt, C. E. Nelson and J. A. Peloubet, Trans. Amer. Inst. Mining Met. Eng. 147 (1942) 273.

E. F. Emley, in “Principles of Magnesium Technology” (Pergamon Press, New York, 1966).

R. E. Lewis, A. Joshi and H. Jones, Proceedings of the International Conference on Enhanced Properties of Structural Materials via Rapid Solidification, Orlando, Florida, Oct. 4–9, 1986 (ASM, Metals Park, Ohio) p. 367.

F. Hehmann and H. Jones, in “Magnesium Technology” (The Institute of Metals, London, 1986) p. 83.

Metals Handbook, 9th Edn, Vol. 10, Material Characterization (ASM, Ohio, 1986) pp. 568, 628.

W.-K. Chu, J. W. Mayer and M. A. Nicolet, in “Backscattering Spectronietry” (Academic Press, New York, 1978).

E. F. Emley, A. C. Jessup and W. F. Higgins, J. Inst. Metals 80 (1951–52) 23.

C. B. Baliga, P. Tsakiropoulos and J. F. Watts, 4 (1989) 231.

A. P. Mattews, C. Jeynes, K. J. Ruson and J. Thornton, Nuclear Instr. Methods 330 (1988) 497.

J. F. Ziegler, in “Helium stopping powers and ranges in all elemental matter” (Pergamon Press, NY, 1977).

D. S. Ahmed, University of Sheffield, unpublished work.

W. Unsworth, Mel, private communication.

J. L. Murray, Bull. Alloy Phase Diagrams 3 (1982) 60.

A. Csanady, I. Betroti, M. Mohai, S. Pereel and B. Albert, Surface Interface Analysis 12 (1988) 229.

N. D. Tomashov, V. S. Komissarova and M. A. Timonova, Issledoran Korrozi Metal, No. 4 (1985) 172.

J. L. Robinson and P. F. King, J. Electrochem. Soc. 108 (1961) 36.

P. F. King, ibid. 113 (1966) 536.

G. Wranglen, in “An introduction to corrosion and protection of metals” (Chapman and Hall, London, 1985).

E. J. Casey and R. E. Bergeron, Canadian J. Chem. 31 (1953) 849.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Baliga, C.B., Tsakiropoulos, P. & Jeynes, C. Surface contamination and its effect on the corrosion of rapidly solidified Mg-Al alloy splats. J Mater Sci 26, 1497–1504 (1991). https://doi.org/10.1007/BF00544658

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00544658