Abstract

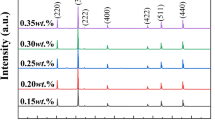

Strontium ferrites (SrO · 5.5Fe2O3) were prepared using hot-rolled mill scale as a source of iron oxides. Calcination was performed at 1200°C for 2 h. The fused B2O3-SiO2, with various mole ratios of B2O3 to SiO2, was added to the calcined ferrites during the milling stage. The ferrites were formed anisotropically. The fused additives are quite effective to enhance the magnetic properties; (BH)max can reach 3.0 MGOe for the ferrite sintered at 1220°C for 2 h. In general, (BH)max is independent of the mole ratio of B2O3 to SiO2 and dominantly influenced by the sintering temperature. The addition of 0.3 or 0.5 wt% fused additives showed no significant difference in the magnet quality. The quality of the magnet was decreased with increasing mole ratio of B2O3 to SiO2 when unfused B2O3-SiO2 was used under the same processing conditions.

Similar content being viewed by others

References

T. J. Gray and R. J. Routil, in “Symposium on Electricity and Magnetisms in Optical Ceramics”, London, 13–14 December (1972) p. 91.

Y. T. Chien and Y. C. Ko, J. Mater. Sci. 25 (1990) 1711.

H. Harada, in “Proceedings of the International Conference on Ferrites”, Japan, September–October (1980) p. 354.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Teng, S.C., Chien, Y.T. & Ko, Y.C. Effect of forms of B2O3-SiO2 as an additive on magnetic properties of SrFe12O19 ferrites. J Mater Sci 27, 2665–2669 (1992). https://doi.org/10.1007/BF00540687

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00540687