Abstract

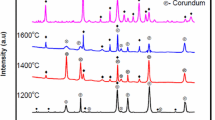

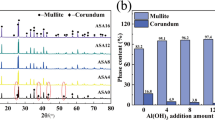

The sinterability of mullite (3Al2O3·2SiO2) powder prepared by chemical vapour deposition was examined to improve the conditions for fabricating dense mullite ceramics. The starting powder contained not only mullite, but also a small amount of γ-Al2O3 (Al-Si spinel) and amorphous material. Although the compressed powder was fired at a temperature between 1550 and 1700 °C for 1, 3 and 5 h, the relative densities of the sintered compacts were limited to ∼ 90%: (i) due to the creation of pores/microcracks during the solid state reaction (1100–1350 °C), and (ii) due to restriction on the rearrangement of grains because the amount of liquid phase (1550–1700 °C) was insufficient. Calcination of the starting powder was effective for preparation of easily sinterable powder with homogeneous composition. When the compact formed by compressing the calcined powder at 1400 °C for 1 h was fired at 1650 °C for 3 h, the relative density was raised up to 97.2%; moreover, mullite was the only phase detected from the sintered compact. The sintered compact was composed of polyhedral grains with sizes of 1–2 μm and elongated grains with long axes of ∼ 6 μm.

Similar content being viewed by others

References

I. A. Aksay and J. A. Pask, J. Amer. Ceram. Soc. 58 (1975) 507.

H. Schneider and E. Eberhard, ibid. 73 (1990) 2073.

S. Kanzaki, T. Kumanaga, J. Asaumi, O. Abe and H. Tabata, J. Ceram. Soc. Jpn 93 (1985) 407.

R. R. Tummala, J. Amer. Ceram. Soc. 74 (1991) 895.

I. A. Aksay, D. M. Dabbs and M. Sarikaya, ibid. 74 (1991) 2343.

M. D. Sacks, H-W. Lee and J. A. Pask, in “Mullite and Mullite Matrix Composites”, edited by S. Sōmiya, R. F. Davis and J. A. Pask (The American Ceramic Society, Westerville, OH, 1990) p. 167.

F. Kara and J. A. Little, J. Mater. Sci. 28 (1993) 1323.

S. Hori and R. Kurita, in “Mullite and Mullite Matrix Composites”, edited by S. Sōmiya, R. F. Davis and J. A. Pask (The American Ceramic Society, Westerville, OH, 1990) p. 311.

K. Itatani, T. Kubozono, A. Kihioka, F. S. Howell and M. Kinoshita, J. Mater. Sci. in press.

P. D. D. Rodrigo and P. Boch, Sci. Ceram. 13 (1985) C1–405.

Powder diffraction file Card No. 15-776 (JCPDS-International Center for Diffraction Data, Swarthmore, PA).

Powder diffraction file Card No. 10-425 (JCPDS-International Center for Diffraction Data, Swarthmore, PA).

P. D. D. Rodrigo and P. Boch, Int. J. High Technol. Ceram. 1 (1985) 3.

A. M. German, “Liquid Phase Sintering” (Plenum Press, New York, 1985) p. 1.

R. F. Davis and J. A. Pask, J. Amer. Ceram. Soc. 55 (1972) 525.

N. Shinohara, D. M. Dabbs and I. A. Aksay, Proc. SPIE-Int. Soc. Opt. Eng. 683 (1986) 19.

K. Itatani, A. Itoh, F. S. Howell, A. Kishioka and M. Kinoshita, J. Mater. Sci. 28 (1993) 719.

M. O. Sacks and J. A. Pask, J. Amer. Ceram. Soc. 65 (1977) 70.

W. G. Fahrenholz, D. M. Smith and J. Cesarano III, ibid. 76 (1993) 433.

J. S. Lee and S. C. Yu, J. Mater. Sci. 27 (1992) 5203.

H. Ohnishi, T. Kawanami, A. Nakahira and K. Niihara, J. Ceram. Soc. Jpn 98 (1990) 541.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Itatani, K., Kubozono, T., Howell, F.S. et al. Some properties of mullite powders prepared by chemical vapour deposition. JOURNAL OF MATERIALS SCIENCE 30, 1196–1202 (1995). https://doi.org/10.1007/BF00356119

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00356119