Abstract

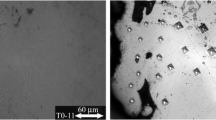

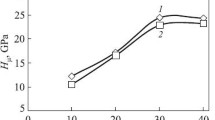

Commercial cermet inserts were coated with titanium nitride by plasma-enhanced chemical vapour deposition (PECVD) using a pulsed direct current (d.c.) glow discharge. The influence of the coating parameters on the deposition rate, on the layer composition, on the layer-substrate interface, on the structure and on the microhardness of the layers was investigated for deposition temperatures in the range 500–700 °C. The adhesive strengths, and some mechanical properties, of the coated cermets were characterized by scratch tests, by friction wear investigations and by measurement of the transverse rupture strength. The wear behaviour was examined in the cutting tests. It was found that TiNx-coatings deposited with a sufficiently high deposition rate and plasma power density have a low oxygen and chlorine content and that they are nearly stoichiometric. The layers usually have a columnar structure with a 〈200〉 texture. A granular, equiaxed structure was observed within a small range of deposition conditions. In interrupted and continuous turning tests with steel and grey cast iron, a high cutting performance of the coated inserts, which depended on the coating thickness and on the deposition temperature, was achieved.

Similar content being viewed by others

References

K. Malle, VDI-Z 134 (1992) 61.

P. Ettmayer and H. Kolaska, Metall. 43 (1989) 742.

J. E. Sundgren and H. T. G. Hentzell, J. Vac. Sci. Technol. A 4 (1986) 2259.

K. Bartsch, A. Leonhardt, E. Wolf, M. Schönherr and M. Seidler, J. Mater. Sci. 22 (1987) 3032.

M. Kato, H. Yoshimura and Y. Fujiwara, Proceedings of the 12th International Plansee Seminar, 8–12 May 1989, Reutte, Tirol, Austria, edited by H. Bildstein and H. M. Ortner (Verlagsanstalt Tyrolia, Innsbruck, 1989) pp. 93–107.

H. Arnold, “Chemisch dampfablagerung” (Akademie-Verlag, Berlin, 1982) p. 34.

D. C. Shah and D. G. Bhat, Surface Modification Technol. IV, edited by T. S. Sundarshan, D. G. Bhat, M. Jeandin (The Minerals, Metals and Materials Society 1991) p. 79.

A. Raveh, Mater. Sci. Engng. A 167 (1993) 155.

Y. Ishii, H. Ohtsu, T. Adachi, H. Ichimura and K. Kobayashi, Surf. Coat. Technol. 49 (1991) 279.

S. Veprek, C. Brendel and H. Schäfer, J. Cryst. Growth 9 (1971) 266.

B. Arnold and I. Endler, to be submitted to Fresenius J. Anal. Chem. 349 (1994) 249.

G. Meunier, J. P. Manaud and P. Grall, Mater. Sci. Engng. B 18 (1993) 303.

J. Laimer, H. Störi and P. Rödhammer, J. Vac. Sci. Technol. A 7 (1989) 2952.

U. C. Oh and J. H. Je, J. Appl. Phys. 74 (1993) 1692.

C. C. Jiang, T. Goto and T. Hirai, J. Alloys Compounds 190 (1993) 197.

V. Valvoda, R. Cerny, R. Kuzel, L. Dobiasova, J. Musil, V. Poulek and J. Vyskocil, Thin Solid Films 170 (1989) 201.

A. J. Perry, J. Vac. Sci. Technol. A 6 (1988) 2140.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Endler, I., Wolf, E., Leonhardt, A. et al. Preparation, characterization and wear behaviour of TiNx-coated cermets obtained by plasma-enhanced chemical vapour deposition. JOURNAL OF MATERIALS SCIENCE 29, 6097–6103 (1994). https://doi.org/10.1007/BF00354548

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00354548