Abstract

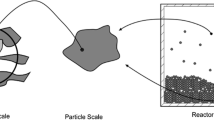

This work deals with the modelling of a travelling bed waste gasifier. This gasifier is a part of a more general process devoted to the production of electricity from waste and refused derived fuel. In a first stage the load is dried and gasified in a travelling bed gasifier using air with an equivalence ratio of 0.3. This product gas contains light hydrocarbons as well as tars. It is converted into a syngas free from tars in a specific reformer (Turboplasma©) that uses plasma technology in order to raise the temperature of the incoming gas to a value compatible with thermal cracking of tars. The model of the travelling bed gasifier is based on the coupling between a software devoted to the description of the chemical and physical processes occurring within the travelling bed, and a CFD package (Fluent™) that allows for the description of the homogenous gas reaction and radiation occurring within the freeboard of the bed. The first software is a “home made” software based on the conservation equations of the solid, liquid and gas phases as well as of the energy. The balance equations are firstly written at the “phase scale”, and then, using a homogenisation technique (volume averaging) balance equations are derived at a representative volume scale. In this first work, this model is written using a one dimensional formalism along the axis of the travelling bed. Wood is used as a case study material with a pyrolysis mechanism that uses three parallel reactions leading to the formation of gas, tars and char. The gas and tars produced during the pyrolysis step can be converted within the bed itself but also over the freeboard of the bed. Hence, the free board of the bed is used as a boundary condition of the CFD domain, with known local mass flow-rate, composition and temperature. This study allows for a complete and precise description of the processes occurring within the gasifier under consideration.

Similar content being viewed by others

Abbreviations

- aw :

-

Water activity

- C:

-

Heat capacity [J kg−1 K−1]

- Cp:

-

Constant pressure heat capacity [J kg−1 K−1]

- D:

-

Diffusivity in the air [m2 s−1]

- \( \underline{\underline{\text{D}}}_{\text{ieff}} \) :

-

Diffusion tensor of i gaseous species in porous medium [m2 s−1]

- \( \underline{\underline{\text{D}}}_{\text{b}} \) :

-

Diffusion tensor of bound water in porous medium [m2 s−1]

- e j :

-

Unit vector in the j direction of space

- f, f :

-

Scalar and vector functions

- Fmi :

-

i species mass flux [kg m−2 s−1]

- g :

-

Gravity vector [m s−2]

- H:

-

Height of the bed [m]

- hi :

-

Intrinsic enthalpy of i gaseous species [J kg−1]

- \( {\bar{\text{h}}}_{\text{b}} \) :

-

Intrinsic averaged enthalpy of bound water [J kg−1]

- hα :

-

Intrinsic averaged enthalpy of free water [J kg−1]

- ∆Hb :

-

Heat of desorption [J kg−1]

- \( \Updelta {\text{H}}_{\text{v}}^{\text{ref}} \) :

-

Latent heat of vaporisation at the reference temperature Tref [J kg−1]

- \( \underline{\underline{\text{k}}} \) :

-

Intrinsic permeability tensor [m²]

- \( \underline{\underline{\text{k}}}_{{{\text{r}}\alpha }} \) :

-

Relative permeability of the α phase in the porous medium [m²]

- l:

-

Width of the porous bed [m]

- L:

-

Length of the porous bed [m]

- m:

-

Molar mass [kg]

- q :

-

Conduction heat flux [W m−2]

- n :

-

Outer unit normal to the product

- P:

-

Pressure [Pa]

- ri :

-

Chemical reaction rate of i species [kg m−3 s−1]

- FQ :

-

Heat flux [W m−2]

- T:

-

Temperature [K or °C]

- t:

-

Time [s]

- t :

-

Unit tangential vector to the product

- V :

-

Velocity [m s−1]

- W:

-

Moisture content (in dry basis)

- Ea:

-

Energy of activation [J mol−1]

- N:

-

Number of gaseous species present in the reactor

- qray :

-

Radiation heat flux [W m−2]

- I:

-

Intensity of the radiation heat flux [W m−2]

- ki :

-

Pre exponential factor in formulae of the homogeneous chemical reaction rate [s−1]

- w :

-

Interface velocity vector [m]

- R:

-

Perfect gas constant

- λ:

-

Thermal conductivity [W m−1 K−1]

- \( \underline{\underline{\lambda }}_{\text{eff}} \) :

-

Effective thermal conductivity tensor [W m−1 K−1]

- ρ:

-

Density [kg m−3]

- μ:

-

Viscosity [kg m−1 s−1]

- \( \bar{\omega }_{\text{i}} \) :

-

Mass fraction of i species in the porous medium

- ωi :

-

Mass fraction of i species in the surroundings

- εα :

-

Volume fraction of the α phase

- φ:

-

Conservative variable

- Γ :

-

Surface flux corresponding to the conservative variable φ

- Π:

-

Production/loss volumetric rate of the conservative variable φ

- α:

-

Phase α

- i:

-

Gaseous species i

- b:

-

Bound water

- s:

-

Solid

- c:

-

Capillarity

- sat:

-

Bound water saturation point

- fo:

-

Formation

- g:

-

Gas

- j:

-

Direction of space

- L:

-

Liquid

- OM:

-

Organic matter

- I:

-

Inorganic matter

- C:

-

Char

- vsat:

-

Vapour saturation

- v:

-

Vapour

- hom:

-

Homogeneous

- het:

-

Heterogeneous

- gasi:

-

Gasification

- pyr:

-

Pyrolysis

- com:

-

Combustion

- 0:

-

Frontier of the porous medium corresponding to x2=0

- H:

-

Interface between the porous medium and the gaseous environment in the reactor

- bed:

-

Porous medium

- 1:

-

Relative to the axial direction of the bed (Ox1)

- 2:

-

Relative to the transverse direction of the bed (Ox2)

- bed:

-

Relative to the bed

- foi:

-

Formation of the i component

- decar:

-

Decarbonation

- L:

-

Liquid phase

- g:

-

Gas phase

- α:

-

α phase

- ref:

-

Reference

- s:

-

Solid

- waste:

-

Waste

- −:

-

Average

- −α :

-

Intrinsec average to the α phase

- \( \nabla \) :

-

Gradient operator

- \( \nabla \cdot \) :

-

Divergence operator

- \( \underline{\underline{\left( \cdot \right)}} \) :

-

Second order tensor

- \( \frac{\text{D}}{\text{Dt}} \) :

-

Material derivative

References

Fourcault, A., Marias, F., Michon, U.: Design of a high temperature chamber fed by a plasma torch for tars thermal removal, pp. 18–20. Nawtec, Chantilly, VA (2009)

Erriguible, A., Bernada, P., Couture, F., Roques, M.: Simulation of convective drying of a porous medium with boundary conditions provided by CFD. Chem. Eng. Res. Des. 84, 113–123 (2006)

Yang, Y.B., Newman, R., Sharifi, V., Swithenbank, J., Ariss, J.: Mathematical modelling of straw combustion in a 38 MWe power plant furnace and effect of operating conditions. Fuel 86, 129–142 (2007)

Yang, Y.B., Ryu, C., Goodfellow, J., Nasserzadeh Sharifi, V., Swithenbank, J.: Modelling waste combustion in grate furnaces. Process Saf. Environ. Prot. 82, 208–222 (2004)

Ménard, Y., Asthana, A., Patisson, F., Sessiecq, Ph, Ablitzer, D.: Thermodynamic study of heavy metals behaviour during municipal waste incineration. Process Saf. Environ. Prot. 84, 290–296 (2006)

Yang, W., Nam, H., Choi, S.: Improvement of operating conditions in waste incinerators using engineering tools. Waste Manage. (Oxford) 27, 607–613 (2004)

Marias, F.: A model of a rotary kiln incinerator including processes occurring within the solid and the gaseous phases. Comput. Chem. Eng. 27, 813–825 (2003)

Marias, F., Roustan, D., Pichat, A.: Modelling of a rotary kiln for the pyrolysis of Aluminium waste. Chem. Eng. Sci. 60, 4609–4622 (2005)

Marias, F., Roustan, D., Pichat, A.: Coupling between CFD and a bed model in a rotary kiln. -Aplication to the pyrolysis of Aluminium waste. Progr. Comput. Fluid Dyn. 7, 40–50 (2007)

Whitaker, S.: Simultaneous heat, mass, and momentum transfer in porous media: a theory of drying. Adv. Heat Transf. 13, 119–203 (1977)

Marle, C.M.: Ecoulements monophasiques en milieu poreux. Rev. Inst. Fr. Petrole 22, 1471–1509 (1967)

Whitaker, S.: Diffusion and dispersion in porous media. AIChE J. 13, 420–427 (1967)

Slattery, J.C.: Flow of viscoelastic fluids through porous media. AIChE J. 13, 1066–1071 (1967)

Gray, W.G.: A derivation of the equation for multiphase transport. Chem. Eng. Sci. 13, 229–233 (1975)

Slattery, J.C.: Advanced transport phenomena. Cambridge Press, Cambridge (1999)

Erriguible A (2004) Modélisation des transferts à l’interface d’un milieu multiphasique et de son environnement, PhD Thesis, Université de Pau, France

Melaaen, M.C.: Numerical analysis of heat and mass transfer in drying and pyrolysis of porous media. Numer. Heat Transf. Part A 29, 331 (1996)

Perré, P., Turner, I.W.: A 3-D version of TransPore: a comprehensive heat and mass transfer computational model for simulating the drying of porous media. Int. J. Heat Mass Transf. 42, 4501–4521 (1999)

Ratte, J., Marias, F., Vaxelaire, J., Bernada, P.: Mathematical modelling of slow pyrolysis of a particle of treated wood waste. J. Hazard. Mater. 170, 1023–1040 (2009)

F. Couture, Modélisation fine d’un problème de séchage, développement d’outils adaptés, PhD Thesis, Université de Bordeaux I, France (1995)

Perré, P., Degiovanni, A.: Simulations par volumes finis des transferts couplés en milieu poreux anisotropes: séchage du bois à basse et à haute temperature. Int. J. Heat Mass Transf. 33(11), 2463–2478 (1990)

Whitaker, S.: Heat and mass transfer in granular porous media. Adv. Drying 1, 23–61 (1980)

Whitaker, S.: Improved constraints for the principle of local thermal equilibrium. Ind. Eng. Chem. Res. 30, 983–997 (1991)

Quintard, M., Whitaker, S.: One- and two-equation models for transient diffusion processes in two-phase system. Adv. Heat Transf. 23, 369–464 (1993)

Wood, B.D., Whitaker, S.: Multi-species diffusion and reaction in biofilms and cellular media. Chem. Eng. Sci. 55, 3397–3418 (2000)

Modélisation des transferts réactifs de masse et de chaleur dans les installations de stockage de déchets ménagers: application aux installations de type bioréacteur, D. Chenu, PhD thesis, INP Toulouse, France (2007)

Whitaker, S.: Moisture transport mechanisms during the drying of granular porous media. Proc. Fourth Int. Drying Symp. 1, 31–42 (1984)

P. Bonneau, Modélisation du séchage d’un matériau hétérogène: application à un bois de résineux, PhD Thesis, Université de Bordeaux I, France (1991)

Puiggali, J.R., Quintard, M.: Properties and simplifying assumptions for classical drying models. Adv. drying 5, 131–147 (1992)

Deydier, A., Marias, F., Couture, F., Bernada, P., Michon, U.: Equilibrium model for a travelling bed gasifier. Biomass Bioenergy 35, 133–145 (2011)

Shafizadeh, F., Chin, P.S.: Thermal deterioration of wood, wood technology: chemical aspects. ACS Symp. Ser. 43, 57–81 (1977)

Thurner, F., Mann, U.: Kinetic investigation of wood pyrolysis. Ind. Eng. Chem. Process Design Dev. 20, 482–488 (1981)

Di Blasi, C.: Modeling and simulation of combustion processes of charring and non-charring solid fuels. Prog. Energy Combust. Sci. 19, 71–104 (1993)

A. Fourcault, F. Marias, U. Michon, Modelling of a high temperature plasma reactor for tar removal, 18th European Biomass Conference, Lyon, 3–7 (2010)

Jess, A.: Mechanisms and kinetics of thermal reactions of aromatic hydrocarbons from pyrolysis of solid fuels. Fuel 75, 1441–1448 (1996)

F. Nozahic. Production de gaz de synthèse par interactions à haute température du gaz, des goudrons et du résidu carboné issus de la pyrolyse de biomasses, Thèse de l’Université de Toulouse (2008)

S.R. Turns. An Introduction to Combustion, Concepts and applications. (1996)

Petersen, I., Werther, J.: Experimental investigation and modeling of gasification of sewage sludge in the circulating fluidized bed. Chem. Eng. Process. 44, 717–736 (2005)

Cooper, J., Hallett, W.L.H.: A numerical model for packed-bed combustion of char particles. Chem. Eng. Sci. 55, 4451–4460 (2000)

Chelliah, H.K., Makino, A., Araki, N., Law, C.K.: Modeling of graphite oxidation in a staganation-point flow field using detailed homogeneous and semi global heterogeneous mechanisms with comparison to experiments. Combust. Flame 104, 469–480 (1996)

Slattery, J.C.: Interfacial transport phenomena. Springer, Berlin (1990)

Erriguible, A., Bernada, P., Couture, F., Roques, M.-A.: Simulation of vacuum drying by coupling models. Chem. Eng. Process. 46(12), 1274–1285 (2006)

Ene, I.H., Sanchez-Palencia, E.: Equations et phénomènes de surface pour l’écoulement dans un modèle de milieu poreux. J. Méc. 14(1), 73–108 (1975)

Gear, C.N., Petzold, L.R.: ODE methods for solution of differential/algebraic systems. J. Num. Anal. 4, 716–728 (1984)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernada, P., Marias, F., Deydier, A. et al. Modelling of a Traveling Bed WASTE Gasifier. Waste Biomass Valor 3, 333–353 (2012). https://doi.org/10.1007/s12649-012-9115-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-012-9115-9